Abstract

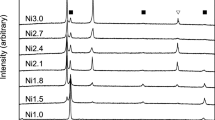

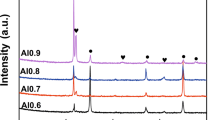

High-entropy alloys Al x CoCrFeMo0.5Ni with varied Al contents (x = 0, 0.5, 1.0, 1.5, and 2.0) have been designed based on the Al x CoCrCuFeNi system to improve mechanical properties for room and elevated temperatures. They have been investigated for microstructure and mechanical properties. As the aluminum content increases, the as-cast structure evolves from face-centered cubic dendrite + minor σ-phase interdendrite at x = 0 to B2 dendrite with body-centered cubic (bcc) precipitates + bcc interdendrite with B2 precipitates at x = 2.0. This confirms the strong bcc-forming tendency of Al. The room-temperature Vickers hardness starts from the lowest, HV 220, at x = 0, attains to the maximum, HV 720, at x = 1.0, and then decreases to HV 615 at x = 2.0. Compared with the base alloy system, the current alloy system has a superior combination of hardness and fracture toughness. In addition, Al x CoCrFeMo0.5Ni alloys except x = 0 display a higher hot hardness level than those of Ni-based superalloys, including In 718 and In 718 H, up to 1273 K and show great potential in high-temperature applications.

Similar content being viewed by others

References

Handbook Committee, Properties and Selection: Irons, Steels, and High Performance Alloys, 10th ed. (Metals Park: ASM International, 1990).

Handbook Committee, ASM Handbook, Properties and Selection: Nonferrous Alloys and Special-Purpose Materials (Metals Park: ASM International, 1990).

C.Y. Hsu, J.W. Yeh, S.K. Chen, and T.T. Shun, Metall. Mater. Trans. A 35, 1465 (2004).

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

J.W. Yeh, Ann Chim. Sci. Mater. 31, 633 (2006).

J.W. Yeh, S.K. Chen, J.Y. Gan, S.J. Lin, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Metall. Mater. Trans. A 35, 2533 (2004).

Y.Y. Chen, T. Duval, U.D. Hung, J.W. Yeh, and H.C. Shih, Corros. Sci. 47, 2257 (2005).

C.J. Tong, M.R. Chen, S.K. Chen, J.W. Yeh, T.T. Shun, S.J. Lin, and S.Y. Chang, Metall. Mater. Trans. A 36, 1263 (2005).

C.J. Tong, Y.L. Chen, S.K. Chen, J.W. Yeh, T.T. Shun, C.H. Tsau, S.J. Lin, and S.Y. Chang, Metall. Mater. Trans. A 36, 881 (2005).

Y.J. Zhou, Y. Zhang, Y.L. Wang, and G.L. Chen, Appl. Phys. Lett. 90, 181904 (2007).

J.M. Zhu, H.F. Zhang, H.M. Fu, A.M. Wang, H. Li, and Z.Q. Hu, J. Alloys Compd. 497, 52 (2010).

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, and P.K. Liaw, Intermetallics 18, 1758 (2010).

C.Y. Hsu, T.S. Sheu, J.W. Yeh, and S.K. Chen, Wear 268, 653 (2010).

C.Y. Hsu, W.R. Wang, W.Y. Tang, S.K. Chen, and J.W. Yeh, Adv. Eng. Mater. 12, 44 (2010).

J.M. Zhu, H.M. Fu, H.F. Zhang, A.M. Wang, H. Li, and Z.Q. Hu, Mater. Sci. Eng. A 527, 6975 (2010).

C.Y. Hsu, C.C. Juan, W.R. Wang, T.S. Sheu, J.W. Yeh, and S.K. Chen, Mater. Sci. Eng. A 528, 3581 (2011).

C.C. Juan, C.Y. Hsu, C.W. Tsai, W.R. Wang, T.S. Sheu, J.W. Yeh, and S.K. Chen, Intermetallics 32, 401 (2013).

Handbook Committee, Alloy Phase Diagrams, 10th ed. (Metals Park: ASM International, 1992).

B.D. Cullity, Elements of X-Ray Diffraction, 2nd ed. (Boston: Addison-Wesley, 1978).

G.E. Dieter, Mechanical Metallurgy, SI Metric Edition (London: McGraw-Hill, 1988).

W.D. Schubert, H. Neumeister, G. Kinger, and B. Lux, Int. J. Refract. Met. Hard Mater. 16, 133 (1998).

K.Y. Tsai, M.H. Tsai, and J.W. Yeh, Acta Mater. 61, 4887 (2013).

Acknowledgements

This research was supported by the National Science Council of Taiwan under grant NSC 100-2221-E-007-049.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hsu, CY., Juan, CC., Sheu, TS. et al. Effect of Aluminum Content on Microstructure and Mechanical Properties of Al x CoCrFeMo0.5Ni High-Entropy Alloys. JOM 65, 1840–1847 (2013). https://doi.org/10.1007/s11837-013-0753-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-013-0753-6