Abstract

Trimodal composites, consisting of nanocrystalline or ultrafine grains (UFGs), coarse grains (CGs), and ceramic particles, were originally formulated to achieve combinations of physical and mechanical properties that are unattainable with the individual phases, such as strength, ductility, and high-strain-rate deformation. The concept of a trimodal structure is both scientifically novel as well as technologically promising because it provides multiple controllable degrees of freedom that allow for extensive microstructure design. The UFGs provide efficient obstacles for dislocation movement, such as grain boundaries and other crystalline defects. The size, distribution, and spatial arrangement of the CGs can be controlled to provide plasticity during deformation. The size, morphology, and distribution of the reinforcement particles can be tailored to attain various engineering and physical properties. Moreover, the interfaces that form among the various phases also help determine the overall behavior of the trimodal composites. In this article, a review is provided to discuss the selection and design of each component in trimodal Al composites. The toughening and strengthening mechanisms in the trimodal composite structure are discussed, paying particular attention to strategies that can be implemented to tailor microstructures for optimal mechanical behavior. Recent results obtained with high-performance trimodal Al composites that contain nanometric reinforcements are also discussed to highlight the ability to control particle–matrix interface characteristics. Finally, a perspective is provided on potential approaches that can be explored to develop the next generation of trimodal composites, and interesting scientific paradigms that evolve from the proposed design strategies are discussed.

Similar content being viewed by others

References

J.C. Ye, B.Q. Han, Z. Lee, B. Ahn, S.R. Nutt, and J.M. Schoenung, Trends in Materials and Manufacturing Technologies for Transportation Industries and Powder Metallurgy Research and Development in the Transportation Industry, ed. T. Bieler, J.E. Carsley, H.L. Fraser, J.W. Sears, and J.E. Smugeresky (Warrendale, PA: TMS, 2005), pp. 383–389.

J. Ye, B.Q. Han, Z. Lee, B. Ahn, S.R. Nutt, and J.M. Schoenung, Scripta Mater. 53, 481 (2005).

H. Zhang, J. Ye, S.P. Joshi, J.M. Schoenung, E.S.C. Chin, and K.T. Ramesh, Scripta Mater. 59, 1139 (2008).

H.T. Zhang, J.C. Ye, S.P. Joshi, J.M. Schoenung, E.S.C. Chin, G.A. Gazonas, and K.T. Ramesh, Adv. Eng. Mater. 9, 355 (2007).

Y. Li, Y.H. Zhao, V. Ortalan, W. Liu, Z.H. Zhang, R.G. Vogt, N.D. Browning, E.J. Lavernia, and J.M. Schoenung, Mater. Sci. Eng. A 527, 305 (2009).

Y. Li, Z. Zhang, R. Vogt, J.M. Schoenung, and E.J. Lavernia, Acta Mater. 59, 7206 (2011).

Z.H. Zhang, T. Topping, Y. Li, R. Vogt, Y.Z. Zhou, C. Haines, J. Paras, D. Kapoor, J.M. Schoenung, and E.J. Lavernia, Scripta Mater. 65, 652 (2011).

R. Vogt, Z. Zhang, E. Huskins, B. Ahn, S. Nutt, K.T. Ramesh, E.J. Lavernia, and J.M. Schoenung, Mater Sci. Eng. A 527, 5990 (2010).

J. Ye, B.Q. Han, and J.M. Schoenung, Philos. Mag. Lett. 86, 721 (2006).

J.M. Schoenung, J. Ye, J. He, F. Tang, and D. Witkin, Mater. Forum 29, 123 (2005).

R.G. Vogt, Z. Zhang, T.D. Topping, E.J. Lavernia, and J.M. Schoenung, J. Mater. Process. Technol. 209, 5046 (2009).

J. Ye, J. He, and J. Schoenung, Metall. Mater. Trans. A 37, 3099 (2006).

Y. Li, Y.H. Zhao, V. Ortalan, W. Liu, Z.H. Zhang, R.G. Vogt, N.D. Browning, E.J. Lavernia, and J.M. Schoenung, Mater. Sci. Eng. A 527, 305 (2009).

R. Vogt, Z. Zhang, Y. Li, M. Bonds, N.D. Browning, E.J. Lavernia, and J.M. Schoenung, Scripta Mater. 61, 1052 (2009).

D. Witkin, Z. Lee, R. Rodriguez, S. Nutt, and E. Lavernia, Scripta Mater. 49, 297 (2003).

D.B. Witkin and E.J. Lavernia, Prog. Mater. Sci. 51, 1 (2006).

E.J. Lavernia, B.Q. Han, and J.M. Schoenung, Mater Sci. Eng. A 493, 207 (2008).

C. Suryanarayana, Prog. Mater. Sci. 46, 1 (2001).

F. Zhou, X.Z. Liao, Y.T. Zhu, S. Dallek, and E.J. Lavernia, Acta Mater. 51, 2777 (2003).

K.K. Ma and J.M. Schoenung, Philos. Mag. Lett. 90, 739 (2010).

K. Ma, E.J. Lavernia, and J.M. Schoenung, Adv. Eng. Mater. 14, 77 (2011).

Y. Li, W. Liu, V. Ortalan, W.F. Li, Z. Zhang, R. Vogt, N.D. Browning, E.J. Lavernia, and J.M. Schoenung, Acta Mater. 58, 1732 (2010).

R. Vogt, Z. Zhang, E. Huskins, B. Ahn, S. Nutt, K.T. Ramesh, E.J. Lavernia, and J.M. Schoenung, Mater. Sci. Eng. A 527, 5990 (2010).

Y. Xiang, T. Li, Z.G. Suo, and J.J. Vlassak, Appl. Phys. Lett. 87, 161910–161911 (2005).

T.H. Fang, W.L. Li, N.R. Tao, and K. Lu, Science 331, 1587 (2011).

K.S. Chan, Metall. Trans. A 23, 183 (1992).

L.R.F. Rose, Int. J. Fract. 31, 233 (1986).

S. Suresh, Metall. Trans. A 16, 249 (1985).

B. Budiansky, J.C. Amazigo, and A.G. Evans, J. Mech. Phys. Solids 36, 167 (1988).

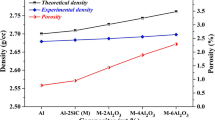

X.Z. Kai, Z.Q. Li, W.L. Zhang, G.L. Fan, L. Jiang, W.J. Lu, and D. Zhang, Mater Sci. Eng. A 530, 574 (2011).

L. Jiang, Z.Q. Li, G.L. Fan, and D. Zhang, Scripta Mater. 65, 412 (2011).

L. Jiang, Z.Q. Li, G.L. Fan, L.L. Cao, and D. Zhang, Scripta Mater. 66, 331 (2012).

Y.T. Zhu and X.Z. Liao, Nat. Mater. 3, 351 (2004).

Y. Li, Y.J. Lin, Y.H. Xiong, J.M. Schoenung, and E.J. Lavernia, Scripta Mater. 64, 133 (2011).

K. Lu, L. Lu, and S. Suresh, Science 324, 349 (2009).

L. Lu, Y.F. Shen, X.H. Chen, L.H. Qian, and K. Lu, Science 304, 422 (2004).

K.C. Chen, W.W. Wu, C.N. Liao, L.J. Chen, and K.N. Tu, Science 321, 1066 (2008).

V. Yamakov, D. Wolf, S.R. Phillpot, A.K. Mukherjee, and H. Gleiter, Nat. Mater. 1, 45 (2002).

X.Z. Liao, Y.H. Zhao, S.G. Srinivasan, Y.T. Zhu, R.Z. Valiev, and D.V. Gunderov, Appl. Phys. Lett. 84, 592 (2004).

H. Van Swygenhoven, Science 296, 66 (2002).

X.Z. Liao, F. Zhou, E.J. Lavernia, S.G. Srinivasan, M.I. Baskes, D.W. He, and Y.T. Zhu, Appl. Phys. Lett. 83, 632 (2003).

B.Q. Han, Z. Lee, D. Witkin, S. Nutt, and E.J. Lavernia, Metall. Mater. Trans. A 36A, 957 (2005).

A. Magee, L. Ladani, T.D. Topping, and E.J. Lavernia, Acta Mater. 60, 5838 (2012).

S. Nelson, L. Ladani, T. Topping, and E. Lavernia, Acta Mater. 59, 3550 (2011).

Z. Lee, V. Radmilovic, B. Ahn, E.J. Lavernia, and S.R. Nutt, Metall. Mater. Trans. A 41A, 795 (2010).

B.M. Ahn, E.J. Lavernia, and S.R. Nutt, J. Mater. Sci. 43, 7403 (2008).

S.P. Joshi, K.T. Ramesh, B.Q. Han, and E.J. Lavernia, Metall. Mater. Trans. A 37A, 2397 (2006).

B.Q. Han, J.Y. Huang, Y.T. Zhu, and E.J. Lavernia, Acta Mater. 54, 3015 (2006).

G.J. Fan, H. Choo, P.K. Liaw, and E.J. Lavernia, Acta Mater. 54, 1759 (2006).

P.S. Pao, H.N. Jones, C.R. Feng, D.B. Witkin, and E.J. Lavernia, Ultrafine Grained Materials IV, ed. Y.T. Zhu, T.G. Langdon, Z. Horita, M.J. Zehetbauer, S.I. Semiatin, and T.C. Lowe (San Antonio, TA: TMS, 2006), pp. 331–336.

Z. Lee, D.B. Witkin, V. Radmilovic, E.J. Lavernia, and S.R. Nutt, Mater. Sci. Eng. A 410, 462 (2005).

R.Q. Ye, B.Q. Han, and E.J. Lavernia, Metall. Mater. Trans. A 36A, 1833 (2005).

J. He, J. Ye, E.J. Lavernia, D. Matejczyk, C. Bampton, and J.M. Schoenung, J. Mater. Sci. 39, 6957 (2004).

R.Q. Ye, B.Q. Han, and E.J. Lavernia, Mater. Res. Soc. Symp. Proc. 821, 313 (2004).

Z.H. Lee, D.B. Witkin, E.J. Lavernia, and S.R. Nutt, Mater. Res. Soc. Symp. Proc. 791, 3 (2004).

Z. Lee, J. Lee, E.J. Lavernia, and S.R. Nutt, Mater. Res. Soc. Symp. Proc. 821, 257 (2004).

F. Zhou, Z. Lee, E.J. Lavernia, and S.R. Nutt, Mater. Res. Soc. Symp. Proc. 821, 83 (2004).

Z. Lee, D.B. Witkin, E.J. Lavernia, and S.R. Nutt, Mater. Res. Soc. Symp. Proc. 740, 21 (2003).

V.L. Tellkamp, A. Melmed, and E.J. Lavernia, Metall. Mater. Trans. A 32, 2335 (2001).

M. Taya, W.D. Armstrong, M. Dunn, and T. Mori, Mater Sci. Eng. A 143, 143 (1991).

X.Z. Kai, Z.Q. Li, G.L. Fan, Q. Guo, Z.Q. Tan, W.L. Zhang, Y.S. Su, W.J. Lu, W.J. Moon, and D. Zhang, Scripta Mater. 68, 555 (2013).

Y.S. Suh, S.P. Joshi, and K.T. Ramesh, Acta Mater. 57, 5848 (2009).

N.A. Fleck, M.F. Ashby, and J.W. Hutchinson, Scripta Mater. 48, 179 (2003).

D.J. Lloyd, Int. Mater. Rev. 39, 1 (1994).

Z. Wang, T.K. Chen, and D.J. Lloyd, Metall. Trans. A 24, 197 (1993).

H.X. Peng, Z. Fan, and J.R.G. Evans, J. Microsc-Oxford 201, 333 (2001).

Z.Y. Fan, Philos. Mag. A 73, 1663 (1996).

Z. Zhou, H.X. Peng, Z. Fan, and D.X. Li, Mater. Sci. Tech. Ser. 16, 908 (2000).

P. Zhang and F.G. Li, Rare Metal Mat. Eng. 39, 1525 (2010).

T.C. Tszeng, Compos. Part B 29, 299 (1998).

G. Liu, G.J. Zhang, F. Jiang, X.D. Ding, Y.J. Sun, J. Sun, and E. Ma, Nat. Mater. 12, 344 (2013).

F. Cai, S.H. Zhang, J.L. Li, Z. Chen, M.X. Li, and L. Wang, Appl. Surf. Sci. 258, 1819 (2011).

L.F. Smith, A.D. Krawitz, P. Clarke, S. Saimoto, N. Shi, and R.J. Arsenault, Mater. Sci. Eng. A 159, L13 (1992).

S. Mukherjee, C.R. Ananth, and N. Chandra, Compos. Sci. Technol. 57, 1501 (1997).

Y.G. Wei, T.P. Li, and H. Xie, Adv. Mater. Res. 33, 591 (2008).

E. Carreno-Morelli, Mater. Sci. Forum 366–3, 570 (2001).

Y.Q. Ning, Z.K. Yao, H.Z. Guo, Y. Tao, and Y.W. Zhang, Chin. J. Mech. Eng. 22, 925 (2009).

F. Chen, X.P. Li, J.Y. Wu, Q. Shen, J.M. Schoenung, and L.M. Zhang, Scripta Mater. 68, 297 (2013).

J.Y. Wu, F. Chen, Q. Shen, J.M. Schoenung, and L.M. Zhang, J. Nanomater. 2013, 1 (2013).

J.R. Song, K.K. Ma, Y. Li, L.M. Zhang, and J.M. Schoenung, Mater Sci. Eng. A 528, 3210 (2011).

J.R. Song, K.K. Ma, L.M. Zhang, and J.M. Schoenung, Surf. Coat. Tech. 205, 1241 (2010).

J.A. Picas, Y. Xiong, M. Punset, L. Ajdelsztajn, A. Forn, and J.M. Schoenung, Int. J. Refract. Met. Hard Mater. 27, 344 (2009).

D.M. Liu, Y.H. Xiong, Y. Li, T.D. Topping, Y.Z. Zhou, C. Haines, J. Paras, D. Martin, D. Kapoor, J.M. Schoenung, and E.J. Lavernia, Metall. Mater. Trans. A 44A, 1908 (2013).

Y.H. Xiong, D.M. Liu, Y. Li, B.L. Zheng, C. Haines, J. Paras, D. Martin, D. Kapoor, E.J. Lavernia, and J.M. Schoenung, Metall. Mater. Trans. A 43A, 327 (2012).

D.M. Liu, Y.H. Xiong, T.D. Topping, Y.Z. Zhou, C. Haines, J. Paras, D. Martin, D. Kapoor, J.M. Schoenung, and E.J. Lavernia, Metall. Mater. Trans. A 43A, 340 (2012).

J.C. Ye, L. Ajdelsztajn, and J.M. Schoenung, Metall. Mater. Trans. A 37A, 2569 (2006).

J.S. Wang, A. Horsfield, P.D. Lee, and P. Brommer, Phys. Rev. B 82, 184203 (2010).

A.M. Bunn, P. Schumacher, M.A. Kearns, C.B. Boothroyd, and A.L. Greer, Mater. Sci. Tech. Ser. 15, 1115 (1999).

T. Qin and Z. Fan, The 3rd International Conference on Advances in Solidification Processes (Materials Science and Engineering, 2011).

A. Kulpa and T. Troczynski, J. Am. Ceram. Soc. 79, 518 (1996).

Acknowledgements

The authors wish to acknowledge financial support for this research. The fundamental studies on structure–property relations in trimodal materials have been funded by the Office of Naval Research (ONR) under the guidance of Dr. Larry Kabacoff (ONR N00014-12-1-0237). Support for the development of trimodal armor systems has been provided by ONR under the guidance of Rod Peterson and Bill Golumbfskie (ONR N00014-03-C-0163 and N00014-12-C-0241) as well as by the Army Research Laboratory (ARL) under the direction of Kyu Cho (ARL W911NF-08-2-0028).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jiang, L., Ma, K., Yang, H. et al. The Microstructural Design of Trimodal Aluminum Composites. JOM 66, 898–908 (2014). https://doi.org/10.1007/s11837-014-0906-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-0906-2