Abstract

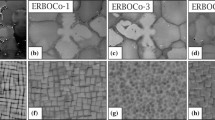

The influence of Ta and Ti additions on microstructural stability and creep behavior in novel Co-Al-W base single-crystal alloys has been investigated. Compared to the ternary alloy, the γ′ solvus temperature and γ′ volume fraction were raised by individual additions of Ta and Ti, and increased further in the quinary alloy containing both alloying additions. In contrast to ternary and quaternary alloys, an improved microstructural stability with the stable γ–γ′ two-phase microstructure and more than 60% γ′ volume fraction existed in the quinary alloy after prolonged aging treatment at 1050°C for 1000 h. The creep behavior at 900°C revealed lower creep rates and longer rupture lives in the quaternary alloys compared to the ternary alloy, whereas the quinary alloy exhibited even better creep resistance. When the creep temperature was elevated to about 1000°C, the creep resistance of the quinary alloy exceeded the previously reported Co-Al-W-base alloys and first-generation Ni-base single-crystal superalloys. The improved creep resistance at approximately 1000°C was considered to be associated with high γ′ volume fraction, γ′ directional coarsening, and dislocation substructure, which included γ–γ′ interfacial dislocation networks and the sheared γ′ precipitates containing stacking faults and anti-phase boundaries.

Similar content being viewed by others

References

R.C. Reed, The Superalloys: Fundamentals and Applications (Cambridge, U.K.: Cambridge University Press, 2006).

T.M. Pollock and S. Tin, J. Propul. Power 22, 361 (2006).

J. Sato, T. Omori, K. Oikawa, I. Ohnuma, R. Karinuma, and K. Ishida, Science 312, 90 (2006).

A. Suzuki and T.M. Pollock, Acta Mater. 56, 1288 (2008).

M.S. Titus, A. Suzuki, and T.M. Pollock, Superalloys 2012, eds. E.S. Huron, R.C. Reed, M.C. Hardy, M.J. Mills, R.E. Montero, P.D. Portella, and J. Telesman (Warrendale, PA: The Minerals, Metals & Materials Society; Hoboken, NJ: John Wiley & Sons, 2012), pp. 823–832.

K. Tanaka, M. Ooshima, N. Tsuno, A. Sato, and H. Inui, Philos. Mag. 92 (2012), pp. 4011–4027.

T.M. Pollock, J. Dibbern, M. Tsunekane, J. Zhu, and A. Suzuki, JOM 62(1), 58 (2010).

T. Omori, K. Oikawa, J. Sato, I. Ohnuma, U.R. Kattner, R. Kainuma, and K. Ishida, Intermetallics 32, 274 (2013).

F. Xue, M. Wang, and Q. Feng, Superalloys 2012, eds. E.S. Huron, R.C. Reed, M.C. Hardy, M.J. Mills, R.E. Montero, P.D. Portella, and J. Telesman (Warrendale, PA: The Minerals, Metals & Materials Society; Hoboken, NJ: John Wiley & Sons, 2012), pp. 813–821.

A. Bauer, S. Neumeier, F. Pyczak, R.F. Singer, and M. Göken, Mater. Sci. Eng. A 550, 333 (2012).

F. Xue, Z.Q. Li, and Q. Feng, Mater. Sci. Forum 654–656, 420 (2010).

F. Xue, M.L. Wang, and Q. Feng, Mater. Sci. Forum 686, 388 (2011).

A. Bauer, S. Neumeier, F. Pyczak, and M. Göken, Superalloys 2012, eds. E.S. Huron, R.C. Reed, M.C. Hardy, M.J. Mills, R.E. Montero, P.D. Portella, and J. Telesman (Warrendale, PA: The Minerals, Metals & Materials Society; Hoboken, NJ: John Wiley & Sons, 2012), pp. 695–703.

M.S. Titus, A. Suzuki, and T.M. Pollock, Scripta Mater. 66, 574 (2012).

F. Xue, H.J. Zhou, X.H. Chen, Q.Y. Shi, H. Chang, M.L. Wang, X.F. Ding, and Q. Feng, Eurosuperalloys 2014, eds. J.Y. Guédou and J. Choné (Les Ulis, France: EDP Sciences, 2014), 15002.

F. Xue, H.J. Zhou, X.F. Ding, M.L. Wang, and Q. Feng, Mater. Lett. 112, 215 (2013).

X.H. Li, B. Gan, Q. Feng, Z.Q. Sun, G.L. Chen, G.Q. Zhang, and L.M. Cao, J. Univ. Sci. Technol. Beijing 30, 1369 (2008).

F. Xue, T. Mi, M.L. Wang, X.F. Ding, X.H. Li, and Q. Feng, Acta Metall. Sin. 50, 845 (2014).

G.L. Erickson and K. Harris, U.S. patent 4643782 (1987).

M. Condat and B. Décamps, Scripta Metall. 21, 607 (1987).

S. Kobayashi, Y. Tsukamoto, and T. Takasugi, Intermetallics 31, 94 (2012).

S. Kobayashi, Y. Tsukamoto, and T. Takasugi, Intermetallics 19, 1908 (2011).

T.M. Pollock and R.D. Field, Dislocations in Solids, Vol. 11, eds. F.R.N. Nabarro and M.S. Duesbery (Amsterdam, The Netherlands: Elsevier, 2002), pp. 547–618.

H. Mughrabi, M. Ott, and U. Tetzlaff, Mater. Sci. Eng. A 234–236, 434 (1997).

P.C.J. Gallagher, Metall. Trans. 1, 2429 (1970).

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China (Nos. 50771012, 51201006, and 51301014), Aeronautical Science Foundation of China (No. 2009ZF74011), and New Century Excellent Talents in University (No. NCET-06-0079). The authors are very grateful to X.H. Li, Z.Q. Li, T. Mi, D.Z. Tang, Y.S. Zhao, Q.Y. Shi, M.L. Wang, X.F. Ding, and H. Chang for their contributions during the investigation of Co-base alloys in the past few years.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xue, F., Zhou, H.J. & Feng, Q. Improved High-Temperature Microstructural Stability and Creep Property of Novel Co-Base Single-Crystal Alloys Containing Ta and Ti. JOM 66, 2486–2494 (2014). https://doi.org/10.1007/s11837-014-1181-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-1181-y