Abstract

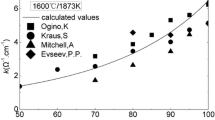

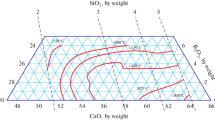

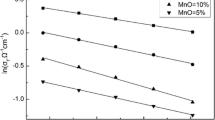

Slag properties, such as electrical conductivity, thermal conductivity, density, viscosity, and surface tension, and the prediction of these properties play an important role in melting and metal refining. Optical basicity depends on the electronegativity of the ions of an individual oxide. This feature represents the bonding characteristics, ionization ability, ion size, and consequently the mobility of free ions inside the slag. These properties affect the electrical conductivity of slags. Therefore, in the current study, various slags containing mainly CaF2 and various oxides were prepared. The optical basicity value of each slag was calculated and their electrical conductivities were measured between 1450°C and 1600°C. The relationship between the optical basicity and the measured properties were discussed. It was observed that increasing optical basicity increases the electrical conductivity as well as the temperature. Thus, a new model for predicting electrical conductivity of slags was built between 1450°C and 1600°C depending on optical basicity and temperature.

Similar content being viewed by others

References

T. Mattar, in 6th International Tooling Conference (TOOL) (Karlstad University Press, Karlstad, 2002), pp. 403–409.

K. Mehrabi, M. Rahimipour, and A. Shokuhfar, Int. J. Iron Steel Soc. Iran 2, 37 (2005).

P. Presoly, J. Korp, and R. Schneider, Arch. Metall. Mater. 53, 1 (2008).

S. Hara, H. Hashimoto, and K. Ogino, Trans. Iron Steel Inst. Jpn. 23, 1053 (1983).

W. Chiho and X. Shunhua, ISIJ Int. 33, 239 (1993).

R.C. Behera and U.K. Mohanty, ISIJ Int. 41, 834 (2001).

J. Björkvall, D. Sichen, and S. Seetharaman, Ironmak. Steelmak. 28, 250 (2001).

K.C. Mills and B.J. Keene, Int. Mater. Rev. 32, 1 (1987).

L. Segers, A. Fontana, and R. Winand, Can. Metall. Quart. 22, 429 (1983).

S.B. Sarkar, ISIJ Int. 9, 348 (1989).

M. Askari and A.M. Cameron, Can. Metall. Q. 30, 207 (1991).

J.A. Duffy and M.D. Ingram, J. Amer. Chem. Soc. 93, 6448 (1971).

J.A. Duffy and M.D. Ingram, J. Inorg. Nucl. Chem. 37, 1203 (1975).

J.A. Duffy, J. Phys. Chem. B 108, 7641 (2004).

K.C. Mills and S. Sridhar, Ironmak. Steelmak. 26, 262 (1999).

A. Kondratiev, E. Jak, and P.C. Hayes, JOM 54 (11), 41 (2002).

K. Mills, Southern African Pyrometallurgy 2011 International Conference (Southern African Institute of Mining and Metallurgy, Johannesburg, 2011), pp. 1–52.

J. Medved, P. Mrvar, V. Gontarev, F. Kavicka, and M. Zdovc, in Paper presented at Metal 2002 (Hradec Nad Moravicí, Czech Republic, 2002), pp. 1–8.

K. Mills, L. Yuan, R. Jones, and J.S. Afr, Inst. Min. Metall. 111, 649 (2011).

G.-H. Zhang and K.-C. Chou, Metall. Mater. Trans. B 41, 131 (2009).

U.B. Pal, C.J. MacDonald, E. Chiang, W.C. Chernicoff, K.C. Chou, J. Avyle, M.A. Molecke, and D. Melgaard, Metall. Mater. Trans. B 32, 1119 (2001).

G.-H. Zhang, K.-C. Chou, and F.-S. Li, Int. J. Miner. Metall. Mater. 16, 500 (2009).

J.T. Ju, Z.L. Lu, Z.Y. Jiao, J. Yang, and Z.H. Zhang, Mater. Sci. Forum 724, 460 (2012).

X.M. Li, S.J. Wang, J.X. Zhao, Y.R. Cui, and Y.M. Chen, Adv. Mater. Res. 239–242, 1960 (2011).

K.W. Peng, P. Zhang, J.G. Xie, and H.L. Ma, Appl. Mech. Mater. 117–119, 269 (2011).

K. Mills and B. Keene, Int. Met. Rev. 26, 21 (1981).

B. Sikora and M. Zielinski, Hutnik 41, 433 (1974).

S. Krauss and G. Neuhof (Doctoral thesis, University of Freiberg, Sachsen, Bergakad. Freiberg, 1973).

A. Mitchell and J. Cameron, Metall. Mater. Trans. B 2, 3361 (1971).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Birol, B., Polat, G. & Saridede, M.N. Estimation Model for Electrical Conductivity of Molten CaF2-Al2O3-CaO Slags Based on Optical Basicity. JOM 67, 427–435 (2015). https://doi.org/10.1007/s11837-014-1230-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-014-1230-6