Abstract

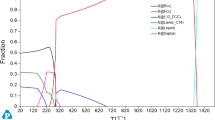

Homogenizing at 1220°C for 20 h and subsequent aging at 900°C for 5 h and 50 h of a novel Al10Co25Cr8Fe15Ni36Ti6 compositionally complex alloy (high-entropy alloy) produces a microstructure consisting of an L12 ordered γ′ phase embedded in a face-centered cubic solid-solution γ matrix together with needle-like B2 precipitates (NiAl). The volume fraction of γ′ phase is ~46% and of needle-like B2 precipitates <5%, which is in accordance with the prediction of calculation of phase diagram method (CALPHAD using Thermo-Calc software with TTNi7 database; Thermo-Calc Software, Stockholm, Sweden). The high-temperature tensile tests were carried out at room temperature, 600°C, 700°C, 800°C, and 1000°C. The tensile strength as well as the elongation to failure of both heat-treated specimens is very high at all tested temperatures. The values of tensile strength has been compared with literature data of well-known Alloy 800H and Inconel 617, and is discussed in terms of the observed microstructure.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Adv. Eng. Mater. 6, 299 (2004).

J.W. Yeh, Y.L. Chen, S.J. Lin, and S.K. Chen, Mater. Sci. Forum 560, 1 (2007).

A. Manzoni, H. Daoud, S. Mondal, S. van Smaalen, R. Völkl, S. Mondal, U. Glatzel, and N. Wanderka, J. Alloy. Compd. 552, 430 (2013).

M.C. Gao and D.E. Alman, Entropy 15, 4504 (2003).

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu, Prog. Mater. Sci. 61, 1 (2014).

A.C. Yeh, Y.J. Chang, C.W. Tsai, Y.C. Wang, J.W. Yeh, and C.M. Kuo, Metall. Mater. Trans. A 45, 184 (2014).

F. Otto, A. Dlouhy, Ch Somsen, H. Bei, G. Eggeler, and E.P. George, Acta Mater. 6, 5743 (2013).

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle, Intermetallics 19, 698 (2011).

O.N. Senkov, J.M. Scott, S.V. Senkova, D.B. Miracle, and C.F. Woodward, J. Alloy. Compd. 509, 6043 (2011).

H.M. Daoud, A. Manzoni, R. Völkl, N. Wanderka, and U. Glatzel, JOM 65, 1805 (2013).

A. Sengupta, S.K. Putatunda, L. Bartosiewicz, J. Hangas, P.J. Nailos, M. Peputapeck, and F.E. Alberts, J. Mater. Eng. Perform. 3, 664 (1994).

L. Müller, U. Glatzel, and M. Feller-Kniepmeier, Acta Metall. Mater. 41, 3401 (1993).

H.M. Daoud, Ph.D. Thesis, Mikrostruktur (2014).

K.B. Zhang, Z.Y. Fua, J.Y. Zhang, W.M. Wang, H. Wang, Q.J. Zhang, J. Shi, and J.Y. Zhang, Mater. Sci. Eng. A 508, 214 (2009).

The Version TCCR, ThermoCalc Software AB, Stockholm, Sweden, 2006. http://www.thermocalc.com.

Thermotech Ni-based Superalloys Database, TTNI7, Version 7.0 (Thermo-Calc Software AB, Stockholm, 2006).

DIN Deutsches Institut für Normung e.v. (Hrsg.), DIN-Taschenbuch 205, Materialprüfnormen für metallische Werkstoffe 3-Mechanische-technologische Prüfverfahren (rzeugnisformabhängig), Schweißverbindungen, Metallklebungen, 3rd ed. (Beuth Verlag, Berlin, 1996), p. 44.

C.J. Tong, Y.L. Chen, S.K. Chen, J.W. Yeh, T.T. Shun, C.H. Tsau, S.J. Lin, and S.Y. Chang, Metall. Mater. Trans. A 36, 881 (2005).

Special Metals Company. http://www.specialmetals.com/documents/Inconel%20alloy%20617.pdf.

Sandmeyer Steel Company. http://www.sandmeyersteel.com/images/Alloy800H-800HT-APR2013.pdf.

A.V. Kuznetsov, D.G. Shaysultnov, N.D. Stepanov, G.A. Salishchev, and O.N. Senkov, Mater. Sci. Eng. A 533, 107 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Daoud, H.M., Manzoni, A.M., Wanderka, N. et al. High-Temperature Tensile Strength of Al10Co25Cr8Fe15Ni36Ti6 Compositionally Complex Alloy (High-Entropy Alloy). JOM 67, 2271–2277 (2015). https://doi.org/10.1007/s11837-015-1484-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1484-7