Abstract

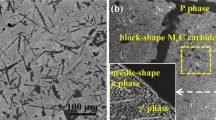

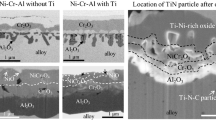

An accurate procedure for predicting oxidation-induced damage and lifetime limits is crucial for the reliable operation of high-temperature metallic components in practical applications. In order to develop a predictive oxidation lifetime model for Ni–Cr alloys, specimens of wrought NiCrW alloy 230 with different thicknesses were cyclically oxidized in air at 950–1050°C for up to 3000 h. After prolonged exposure, two types of carbides as well as a Cr-rich nitride (π-phase) precipitated in the γ-Ni matrix. The oxidation-induced loss of Cr from the alloy resulted in the formation of subscale zones, which were free of the Cr-rich carbide and nitride but also of the Ni-W rich M6C. The width of the M6C-free zone was smaller than that free of the Cr-rich precipitates. Thermodynamic and diffusion calculations of the observed time- and temperature-dependent Cr depletion processes identified that back diffusion of C occurred which resulted in an increased volume fraction of M23C6 in the specimen core. With increasing time and temperature, the amount of π-phase in the specimen core increased. The subscale depletion of the initially present Cr-nitrides and the formation of Cr-nitrides in the specimen center is believed to be related to a mechanism which is qualitatively similar to that described for the Cr carbide enrichment. However, with increasing time and decreasing specimen thickness, N uptake from the atmosphere becomes apparent. As a result, the precipitates present in the specimen center eventually consisted almost exclusively of nitrides.

Similar content being viewed by others

References

D.J. Young, High Temperature Oxidation and Corrosion of Metals (Oxford: Elsevier, 2008), p. 196.

A.V. Dean and P.J. Ennis, Nucl. Technol. 66, 117 (1984).

W.R. Johnson, L.D. Thompson, and T.A. Lechtenberg, Nucl. Technol. 66, 88–101 (1984).

R.H. Cook, Nucl. Technol. 66, 283 (1984).

H.M. Tawancy, J. Mater. Sci. 27, 6481 (1992).

D.L. Klarstrom and G.Y. Lai, Proceedings 6th International Symposium on Superalloys (Seven Springs, PA, Sept. 18–22, 1988).

P.J. Ennis, W.J. Quadakkers, and H. Schuster, Mater. Sci. Technol. 8, 78 (1992).

U. Bruch, D. Schuhmacher, P.J. Ennis, and E. te Heesen, Nucl. Technol. 66, 357 (1984).

N. Birks, G.H. Meier, and F.S. Petit, Introduction to the High-Temperature Oxidation of Metals (Cambridge: Cambridge University Press, 2006), p. 101.

R. Bauer, M. Baccalaro, L.P.H. Jeurgens, M. Pohl, and E.J. Mittemeijer, Oxid. Met. 69, 265 (2008).

H.E. Evans and A.T. Donaldson, Oxid. Met. 50, 457 (1998).

D.P. Whittle, D.J. Evans, D.B. Scully, and G.C. Wood, Acta Metall. 15, 1421 (1967).

H. Ackermann, G. Teneva-Kosseva, H. Koehne, K. Lucka, S. Richter, and J. Mayer, Mater. Corros. 59, 380 (2008).

U. Brill, Metallurgy 46, 778 (1992).

U. Brill and J. Klöwer, Metallurgy 51, 263 (1997).

R. Pillai, H. Ackermann, H. Hattendorf, and S. Richter, Corros. Sci. 75, 28 (2013).

R. Pillai, H. Ackermann, and K. Lucka, Corros. Sci. 69, 181 (2013).

R.N. Durham, B. Gleeson, and D.J. Young, Oxid. Met. 50, 139 (1998).

P.J. Maziasz, B.A. Pint, J.P. Shingledecker, N.D. Evans, Y. Yamamoto, K.L. More, and E. Lara-Curzio, Int. J. Hydrogen Energy 32, 3622 (2007).

R. Duan, A. Jalowicka, P. Huczkowski, B. Pint and W.J. Quadakkers, Forschungszentrum Juelich GmbH, unpublished research (2015).

B.A. Pint, P.T. Tortorelli, and I.G. Wright, Oxid. Met. 58, 73 (2002).

W.J. Quadakkers, A. Elschner, W. Speier, and H. Nickel, Appl. Surf. Sci. 52, 271 (1991).

A. Chyrkin, R. Pillai, H. Ackermann, H. Hattendorf, S. Richter, W. Nowak, D. Grüner, and W.J. Quadakkers, Corros. Sci. 96, 32 (2015).

“High Temperature Tech Brief” Haynes International, 2009, http://www.haynesintl.com/pdf/h3060.pdf. Accessed 16 July 2015.

B.D. Bastow, D.P. Whittle, and G.C. Wood, Oxid. Met. 12, 413–438 (1978).

D. Klarstrom, Corrosion, 407/1-407/12 (1994).

L. Jiang, R. Hu, H. Kou, J. Li, G. Bai, and H. Fu, Mater. Sci. Eng. A 536, 37 (2012).

P. Subramanya Herle, M.S. Hegde, K. Sooryanarayana, T.N. Guru Row, and G.N. Subbanna, J. Mater. Chem. 8, 1435 (1998).

V. Gavriljuk and H. Berns, High Nitrogen Steels, Structure, Properties, Manufacture, Applications (Berlin: Springer, 1999).

C.S. Giggins and F.S. Pettit, J. Electrochem. Soc. 118, 1782 (1971).

C.S. Tedmon, J. Electrochem. Soc. 113, 766 (1966).

H.C. Graham and H.H. Davis, J. Am. Ceram. Soc. 54, 89 (1971).

D. Young and B. Pint, Oxid. Met. 66, 137 (2006).

M. Michalik, M. Hänsel, J. Zurek, L. Singheiser, and W.J. Quadakkers, Mater. High Temp. 22, 213 (2005).

D. Kim, C. Jang, and W.S. Ryu, Oxid. Met. 71, 271 (2009).

W.J. Quadakkers, J. Piron-Abellan, V. Shemet, and L. Singheiser, Mater. High Temp. 20, 115 (2003).

“MNX - MEMS and Nanotechnology Exchange” https://www.memsnet.org/material/chromiumoxidecr2o3bulk/?keywords=chromium%20oxide. Accessed 08 July 2015.

H. Evans, Int. Mater. Rev. 40, 1 (1995).

W.J. Quadakkers, P. Huczkowski, D. Naumenko, J. Zurek, G.H. Meier, L. Niewolak, and L. Singheiser, Mater. Sci. Forum 595–598, 1111 (2008).

J. Zurek, G.H. Meier, E. Essuman, M. Hänsel, L. Singheiser, and W.J. Quadakkers, J. Alloys Compd. 467, 450 (2009).

W.J. Quadakkers and L. Singheiser, Mater. Sci. Forum 369, 77 (2001).

S. Osgerby, K. Berriche-Bouhanek, and H.E. Evans, Mater. Sci. Eng. A 412, 182 (2005).

A. Baldan, J. Mater. Sci. 37, 2171–2202 (2002).

A. Chyrkin, P. Huczkowski, V. Shemet, L. Singheiser, and W.J. Quadakkers, Oxid. Met. 75, 143 (2010).

K. Ledjeff, A. Rahmel, and M. Schorr, Werkst. Korros. 30, 767 (1979).

P. Berthod, C. Vebert, L. Aranda, R. Podor, and C. Rapin, Oxid. Met. 63, 57 (2005).

R. Petkovic-Luton and T.A. Ramanarayanan, Oxid. Met. 34, 381 (1990).

W.J. Quadakkers, Mat. Sci. Eng. 87, 107 (1987).

“MNX - MEMS and Nanotechnology Exchange” http://www.memsnet.org/material/nickelnibulk/?keywords=nickel. Accessed 08 July 2015.

P. Villars, “Material Phases Data System (MPDS)” (Springer-Verlag GmbH, Heidelberg, 2014) http://materials.springer.com/isp/crystallographic/docs/sd_0540673. Accessed 09 July 2015.

P. Villars, “Material Phases Data System (MPDS)” (Springer-Verlag GmbH, Heidelberg, 2014) http://materials.springer.com/isp/crystallographic/docs/sd_1008647.Accessed 09 07 2015.

Acknowledgements

The authors would like to acknowledge Dr. K. Ohla from Haynes International for supplying the material. The authors would also like to acknowledge the Bundesministerium für Bildung und Forschung (BMBF) for funding part of this work under Grant No. 03EK3032. Assistance with ICP-OES analysis provided by H. Lippert and V. Nischwitz from the Central Institute for Engineering, Electronics and Analytics, ZEA-3, Forschungszentrum Jülich GmbH is greatly appreciated. The authors are grateful to the following colleagues in the Institute of Energy and Climate Research of the Forschungszentrum Jülich GmbH IEK-2 for assistance in the experimental work: R. Mahnke, H. Cosler, and A. Kick for the oxidation experiments, V. Gutzeit and J. Bartsch for metallographic studies, Dr. E. Wessel for EBSD investigations and Dr. Nowak for GDOES analyses. At ORNL, G. Garner, T. Lowe and T. Jordan assisted with the experimental work and the research was sponsored by the U.S. Department of Energy, U.S. Assistant Secretary for Energy Efficiency and Renewable Energy, Advanced Manufacturing Office (Combined Heat and Power Program).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jalowicka, A., Duan, R., Huczkowski, P. et al. Effect of Specimen Thickness on Microstructural Changes During Oxidation of the NiCrW Alloy 230 at 950–1050°C. JOM 67, 2573–2588 (2015). https://doi.org/10.1007/s11837-015-1645-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-015-1645-8