Abstract

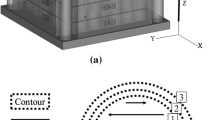

During the electron beam melting (EBM) process, builds occur at temperatures in excess of 800°C for nickel-base superalloys such as Inconel 718. When coupled with the temporal differences between the start and end of a build, a top-to-bottom microstructure gradient forms. Characterized in this study is a microstructure gradient and associated tensile property gradient common to all EBM Inconel 718 builds, the extent of which is dependent on build geometry and the specifics of a build’s processing history. From the characteristic microstructure elements observed in EBM Inconel 718 material, the microstructure gradient can be classified into three distinct regions. Region 1 (top of a build) is comprised of a cored dendritic structure that includes carbides and Laves phase within the interdendritic regions. Region 2 is an intermediate transition zone characterized by a diffuse dendritic structure, dissolution of the Laves phase, and precipitation of \(\delta \) needle networks within the interdendritic regions. The bulk structure (Region 3) is comprised of a columnar grain structure lacking dendritic characteristics with \(\delta \) networks having precipitated within the grain interiors. Mechanically, at both 20°C and 650°C, the yield strength, ultimate tensile strength, and elongation at failure exhibit the general trend of increasing with increasing build height.

Similar content being viewed by others

References

H.J. Wagner, and A.M. Hal, Tech. Rep. (Battelle Memorial Institue, Columbus, 1965)

C. Sims, The Superalloys (Wiley, New York, 1972)

J.F. Radavich, in Superalloy 718: Metallurgy and Applications, ed. by E. Loria (Minerals, Metals & Materials Society, USA, 1989), pp. 229–240

I. Gibson, D. Rosen, and B. Stucker, Additive Manufacturing Technologies (Springer, New York, 2010)

H.E. Helmer, C. Körner, and R.F. Singer, J. Mater. Res. 29, 1987 (2014)

W. Sames, K. Unocic, R. Dehoff, T. Lolla, and S. Babu, J. Mater. Res. 29, 1920 (2014)

Y. Tian, D. McAllister, H. Colijn, M. Mills, D. Farson, M. Nordin, and S. Babu, Metall. Mater. Trans. A 45, 4470 (2014)

K. Unocic, L. Kolbus, R. Dehoff, S. Dryepondt, and B. Pint, Corrosion (NACE International, USA, 2014)

K. Amato, S. Gaytan, L. Murr, E. Martinez, P. Shindo, J. Hernandez, S. Collins, and F. Medina, Acta Mater. 60, 2229 (2012)

Z. Wang, K. Guan, M. Gao, X. Li, X. Chen, and X. Zeng, J. Alloys Compd. 513, 518 (2012)

A. Strondl, R. Fischer, G. Frommeyer, and A. Schneider, Mater. Sci. Eng. A 480, 138 (2008)

L. Carter, M. Attallah, and R. Reed, in Superalloys 2012, ed. by E. Huron, R. Reed, M. Hardy, M. Mills, R. Montero, P. Portella, and J. Telesman (Wiley, New York, 2012), p. 577

L. Murr, E. Martinez, X. Pan, S. Gaytan, J. Castro, C. Terrazas, F. Medina, R. Wicker, and D. Abbott, Acta Mater. 61, 4289 (2013)

L. Murr, E. Martinez, S. Gaytan, D. Ramirez, B. Machado, P. Shindo, J. Martinez, F. Medina, J. Wooten, D. Ciscel, U. Ackelid, and R. Wicker, Metall. Mater. Trans. A 42, 3491 (2011)

ASTM E08–13a, Standard Test Methods for Tension Testing of Metallic Mater. Tech. Rep. (ASTM International, 2013)

ASTM E21–09, Standard Test Methods for Elevated Temperature Tension Tests of Metallic Mater. Tech. Rep. (ASTM International, 2009)

R.G. Thompson, and S. Genculc, Weld. Res. Supp. 337, (1983)

R. Thompson, JOM 40, 44 (1988)

S. David, S. Babu, and J. Vitek, JOM 55, 14 (2003)

S. Babu, M. Miller, J. Vitek, and S. David, Acta Mater. 49, 4149 (2001)

M. Gäumann, C. Bezençon, P. Canalis, and W. Kurz, Acta Mater. 49, 1051 (2001)

J.D. Hunt, Mater. Sci. Eng. 65, 75 (1984)

J. Tien, and T. Caulfield, Superalloys, Supercomposites, and Superceramics (Academic, New York, 1989)

Y. Zhang, Z. Li, P. Nie, and Y. Wu, Metall. Mater. Trans. A 44, 5513 (2013)

W. Kurz, B. Giovanola, and R. Trivedi, Acta Metall. 34, 823 (1986)

A. Devaux, L. Nazé, R. Molins, A. Pineau, A. Organista, J. Guédou, J. Uginet, and P. Héritier, Mater. Sci. Eng. A 486, 117 (2008)

G. Bouse, in Superalloys 718, 625 and Various Derivatives, 1989, ed. by E. Loria, p. 69

J. Schirra, R. Caless, and R. Hatala, in Superalloys 718, 625 and Various Derivatives, 1989, ed. by E. Loria, p. 375

G. Sjoberg, N. Ingesten, and R. Carlson, in Superalloys 718, 625 and Various Derivatives, 1989, ed. by E. Loria, p. 603

X. Liang, R. Zhang, Y. Yang, and Y. Han, in Superalloys 718, 625, 706 and Various Derivatives, 1994, ed. by E. Loria, p. 947

M. Sundararaman, P. Mukhopadhyay, and S. Banerjee, Mater. Trans. A 19, 453 (1988)

J.M. Oblak, D.F. Paulonis, and D.S. Duvall, Metall. Mater. Trans. 5, 143 (1974)

M. Sundararaman, and P. Mukhopadhyay, Mater. Char. 31, 191 (1993)

D.A. Korzekwa, Int. J. Cast Metals Res. 22, 187 (2009)

W. Cao, R. Kennedy, and M. Willis. in Superalloys 718, 625 and Various Derivatives, 1991, ed. by E. Loria, p. 147

G.A. Rao, M. Srinivas, and D. Sarma, Mater. Sci. Technol. 20, 1161 (2004)

H. Zhang, S. Zhang, M. Cheng, and Z. Li, Mater. Char. 61, 49 (2010)

S. Azadian, L.-Y. Wei, and R. Warren, Mater. Char. 53, 7 (2004)

S. Wlodek, and D. Field, in Superalloys 718, 625, 706 and Various Derivatives, 1994, ed. by E. Loria, p. 659

M.C. Chaturvedi, and Y.-F. Han, Metal Sci. 17, 145 (1983)

A. Argon, Strengthening Mechanisms in Crystal Plasticity (Oxford University Press, New York, 2007), pp. 113–144

Acknowledgements

This research is sponsored by the US Department of Energy, Office of Energy Efficiency and Renewable Energy, Advanced Manufacturing Office, under Contract DE-AC05-00OR22725 with UT-Battelle, LLC. The United States Government retains, and the publisher, by accepting the article for publication, acknowledges that the United States Government retains, a non-exclusive, paid-up, irrevocable, worldwide license to publish or reproduce the published form of this manuscript, or allow others to do so, for United States Government purposes. This research was performed, in part, using instrumentation provided by the Department of Energy, Office of Nuclear Energy, Fuel Cycle R&D Program and the Nuclear Science User Facilities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kirka, M.M., Unocic, K.A., Raghavan, N. et al. Microstructure Development in Electron Beam-Melted Inconel 718 and Associated Tensile Properties. JOM 68, 1012–1020 (2016). https://doi.org/10.1007/s11837-016-1812-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-016-1812-6