Abstract

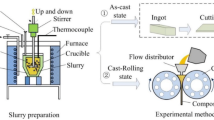

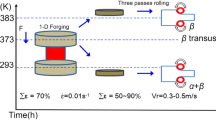

Al-4.5wt.%Cu-5wt.%TiB2 in situ composite, fabricated by stir casting through a mixed salt reaction route process, needs further processing to exclude casting defects. Mushy state rolling has been developed as an easy and energy-efficient method for microstructural refinement and improvement in mechanical properties. It has been carried out at 621°C and 632°C with 20 vol.% and 30 vol.% of liquid, respectively, for up to 5% reduction in thickness. Mushy state rolling of the as-cast composite gives rise to a bimodal microstructure, which consists of very fine equiaxed grains adjacent to the rolled surface and comparatively larger elongated grains away from the rolled surface of the sample. Microhardness of the mushy state rolled sample has been observed to decrease gradually from edge to center of the rolled sample. The presence of the dislocation tangles and subgrains formed by dynamic recovery within solid-state deformed elongated grains and formation of recrystallized grains just adjacent to the second-phase particles have been examined with the help of electron backscattered diffraction and transmission electron microscopy analysis.

Similar content being viewed by others

References

S. Rawal, JOM 53, 14 (2001).

B.S.B. Reddy, K. Das, and S. Das, J. Mater. Sci. 42, 9366 (2007).

S. Suresh, N. Shenbag, and V. Moorthi, Proc. Eng. 38, 89 (2012).

S.C. Tjong and K.C. Lau, Mater. Sci. Technol. 16, 99 (2000).

I.G. Siddhalingeshwar, D. Deepthi, M. Chakraborty, and R. Mitra, Wear 271, 748 (2011).

A.V. Smith and D.D.L. Chung, J. Mater. Sci. 31, 5961 (1996).

S.C. Tjong, S.Q. Wu, and H.G. Zhu, Compos. Sci. Technol. 59, 1341 (1999).

M.A. Herbert, C. Sarkar, R. Mitra, and M. Chakraborty, Wear 265, 1606 (2008).

R. Ipek, J. Mater. Process. Technol. 162, 71 (2005).

R.G. Munro, J. Res. Natl. Inst. Stand. Technol. 105, 709 (2000).

R. Mitra, W.A. Chiou, M.E. Fine, and J.R. Weertman, J. Mater. Res. 8, 2380 (1993).

M.A. Herbert, C. Sarkar, R. Mitra, and M. Chakraborty, Metall. Mater. Trans. A 38, 2110 (2007).

I.G. Siddhalingeshwar, M. Chakraborty, M. Herbert, and R. Mitra, Mater. Sci. Eng. A 528, 1787 (2011).

M.C. Flemings, Solidification Processing (New York: McGraw-Hill Book Co., 1974), pp. 22–23.

M. Kiuchi and R. Kopp, J. Jpn. Soc. Technol. Plastic. 20, 826 (1979).

J. Corrochano, P. Hidalgo, M. Leblich, and J. Ibáñez, Mater. Char. 61, 1294 (2010).

D.J. Jensen, N. Hansen, and F.J. Humphreys, Acta Metall. 33, 2155 (1985).

N. Hansen and B. Bay, Acta Metall. 29, 65 (1981).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mandal, M., Mitra, R. Effect of Mushy State Rolling on the Microstructure, Microhardness, and Microtexture in Al-4.5wt.%Cu-5wt.%TiB2 In Situ Composite. JOM 68, 1902–1908 (2016). https://doi.org/10.1007/s11837-016-1911-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-016-1911-4