Abstract

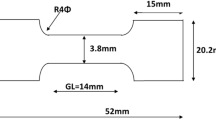

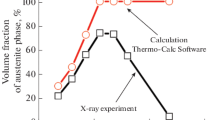

The effects of adiabatic heating during deformation of a medium-manganese transformation-induced plasticity steel containing 10.1Mn-1.68Al-0.14C-0.2Si (wt.%) processed with initially 57 vol.% retained austenite were investigated over the temperature range from − 60°C to 100°C at strain rates from 0.002 s−1 to 0.2 s−1. Tensile tests were performed on specimens immersed in isothermal baths, which reduced but did not completely eliminate adiabatic heating. The specimen temperature depended on the extent of adiabatic heating, which increased with strain and strain rate. The measured properties primarily reflected the effects of temperature on austenite stability and the corresponding resistance of austenite transformation to martensite with strain. Changes in austenite stability were monitored by measurements of austenite fractions at a specific strain and observation of microstructures after deformation. The results of this study provide a basis to identify input material parameters required for numerical models applicable to sheet metal forming of medium-Mn steels.

Adapted from Ref. 3

Reprinted with permission from Ref. 3

Adapted based on predictions of Pereira and Rolfe18

Similar content being viewed by others

References

P.J. Gibbs, E. De Moor, M.J. Merwin, B. Clausen, J.G. Speer, and D.K. Matlock, Metall. Mater. Trans. A 42A, 3691 (2011).

R. Rana, P.J. Gibbs, E. De Moor, J.G. Speer, and D.K. Matlock, Steel Res. Int. 86, 1139 (2015).

R. Rana, D.K. Matlock, J.G. Speer, and E. De Moor, in Proceedings of the 1st International Conference on Automobile Steel and the 3rd International Conference on High Manganese Steels, ed. By Haiwen Luo (Beijing, Metallurgical Industry Press, 2016) pp. 119–122.

D.W. Suh, J.H. Ryu, M.S. Joo, H.S. Yang, K.Y. Lee, and H.K.D.H. Bhadeshia, Metall. Mater. Trans. A 46A, 286 (2013).

Y. Ma, Mater. Sci. Technol. 33, 1713 (2017).

Y.-K. Lee and J. Han, Mater. Sci. Technol. 31, 843 (2015).

B.C. De Cooman, in Automotive Steels: Design, Metallurgy, Processing and Applications, ed. R. Rana and S. B. Singh (London: Elsevier, 2016), p. 317.

B. Hu, H. Luo, F. Yang, and H. Dong, J. Mater. Sci. Technol. (2017). https://doi.org/10.1016/j.jmst.2017.06.017.

D.K. Matlock and J.G. Speer, Microstructure and Texture in Steels and Other Materials, ed. by A. Haldar, S. Suwas, and D. Bhattacharjee (London: Springer, 2009) p. 185.

D.K. Matlock, J.G. Speer, E. De Moor, and P.J. Gibbs, Eng. Sci. Technol. Int. J. (JESTECH) 15, 1 (2012).

Y. Zhang, L. Wang, K.O. Findley, and J.G. Speer, Metall. Mater. Trans. A 48A, 2140 (2017).

G. Frommeyer, U. Brüx, and P. Neumann, ISIJ Int. 43, 438 (2003).

I. Tamura, Metal. Sci. 16, 245 (1982).

S. Curtze and V.-T. Kuokkala, Acta Mater. 58, 5129 (2010).

P. Hora, P. Peters, N. Manopulo, and M. Gorji, in Proceedings of Advanced Constitutive Models in Sheet Metal Forming (Zurich: Institute of Virtual Manufacturing, 2015), pp. 3–9.

S. Bruschi, T. Altan, D. Banabic, P.F. Bariani, A. Brosius, J. Cao, A. Ghiotti, M. Khraisheh, M. Merklein, and A.E. Tekkaya, CIRP Ann. Manuf. Technol. 63, 727 (2014).

M.A. Ablat and A. Qattawi, Int. J. Adv. Manuf. Technol. 89, 1235 (2017).

M.P. Pereira and B.F. Rolfe, J. Mater. Process. Technol. 214, 1749 (2014).

M. Callahan, O. Hubert, F. Hild, A. Perlade, and J.-H. Schmitt, Mater. Sci. Eng. A 704, 391 (2017).

Y.F. Shen, N. Jia, R.D.K. Misra, and L. Zuo, Acta Mater. 103, 229 (2016).

G.S. Langdon and G.K. Schleyer, J. Strain Anal. Eng. Des. 39, 71 (2004).

B.K. Choudhary, Metall. Mater. Trans. A 45A, 302 (2004).

G.B. Olson, in Deformation, Processing, and Structure, ed. by G. Krauss (Metals Park: ASM, 1984) pp. 391–424.

C.-C. Li and W.C. Leslie, Metall. Trans. A 9A, 1765 (1978).

P. Verleysen, J. Peirs, J. Van Slycken, K. Faes, and L. Duchene, J. Mater. Process. Technol. 211, 1457 (2011).

Acknowledgement

The authors acknowledge support of the corporate sponsors of the Advanced Steel Processing and Products Research Center at the Colorado School of Mines. This material is based upon work supported by the Department of Energy National Energy Technology Laboratory under Award No. DE-EE0005976. This report was prepared as an account of work sponsored by an agency of the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency thereof.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rana, R., De Moor, E., Speer, J.G. et al. On the Importance of Adiabatic Heating on Deformation Behavior of Medium-Manganese Sheet Steels. JOM 70, 706–713 (2018). https://doi.org/10.1007/s11837-018-2779-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-2779-2