Abstract

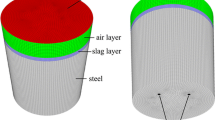

A three-dimensional discrete phase model–volume of fluid coupled model has been developed to study the argon/steel/slag/air multiphase flow and mixing phenomena in an industrial gas-stirred ladle taking the coalescence, expansion and breakup of the argon bubbles as well as the fluctuant slag layer into account. The simulated results of the flow rate and bubble size evolution of the water model, as well as the slag eye size, are in good agreement with the experimental results reported in the literature. The modeling results show that the expansion of bubbles has a significant impact on the bubble size evolution and multiphase flow in an industrial ladle. The effects of different plug configurations on the flow characteristics and mixing time in the ladle are also investigated.

Similar content being viewed by others

References

W. Lou and M. Zhu, Metall. Mater. Trans. B 45, 1706 (2014).

U.C. Bandara, S.M. Asce, P.D. Yapa, and M. Asce, J. Hydraul. Eng. 137, 729 (2011).

C. Chen, Q. Rui, and G. Cheng, Steel Res. Int. 84, 900 (2013).

S.T. Johansen and F. Boysan, Met. Trans. B 19b, 755 (1988).

Y. Xie, S. Orsten, and F. Oeters, ISIJ Int. 32, 66 (1992).

L. Zhang, Model. Simul. Mater. Sci. Eng. 8, 463 (2000).

S.W.P. Cloete, J.J. Eksteen, and S.M. Bradshaw, Prog. Comput. Fluid Dyn. 9, 345 (2009).

L. Zhang, J. Aoki, and B.G. Thomas, Metall. Mater. Trans. B 37, 361 (2006).

G. Chen, S. He, and Y. Li, Metall. Mater. Trans. B 48, 2176 (2017).

H. Liu, Z. Qi, and M. Xu, Steel Res. Int. 82, 440 (2011).

W. Lou and M. Zhu, Metall. Mater. Trans. B 44, 762 (2013).

W. Lou and M. Zhu, ISIJ Int. 54, 9 (2014).

ANSYS Fluent 17.1, User’s Guide (ANSYS, Inc.)

Q. Cao, A. Pitts, and L. Nastac, Ironmak. Steelmak. (2016). https://doi.org/10.1080/03019233.2016.1262574.

J. Olsen and S. Cloete, in 7th International Conference on CFD in the Minerals and Process Industries, vol. 1 (2009).

J. Xia, T. Ahokainen, and L. Holappa, 2nd International Conference on CFD in the Minerals and Process Industries, vol. 187 (1999).

M. Sano and K. Mori, J. Iron Steel Inst. Jpn. 17, 344 (1975).

P.J. O’Rourke, Collective Drop Effects on Vaporizing Liquid Sprays (Los Alamos: Los Alamos National Lab., 1981).

L.F. Zhang and S. Taniguchi, Int. Mater. Rev. 45, 59 (2000).

M. Sevik and S.H. Park, J. Fluids Eng. 95, 53 (1973).

S.-H. Kim and R.J. Fruehan, Metall. Trans. B 18, 673 (1987).

L. Nastac, D. Zhang, Q. Cao, A. Pitts, and R. Williams, CFD Modeling and Simulation in Materials Processing 2016 (Berlin: Springer, 2016), pp. 187–194.

Q. Cao and L. Nastac, Metall. Mater. Trans. B (2018). https://doi.org/10.1007/s11663-018-1206-y.

Q. Cao and L. Nastac, Ironmak. Steelmak. (2018). https://doi.org/10.1080/03019233.2018.1426697.

Y.Y. Sheng and G.A. Irons, Metall. Mater. Trans. B 26, 625 (1995).

K. Krishnapisharody and G.A. Irons, ISIJ Int. 48, 1807 (2008).

L. Li and B. Li, JOM 68, 2160 (2016).

D. Mazumdar and R.I.L. Guthrie, ISIJ Int. 35, 1 (1995).

J. Aoki, B.G. Thomas, and K.D. Peaslee, in AISTech 2004 Proceedings I, vol. 1045 (2004)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cao, Q., Nastac, L. Mathematical Modeling of the Multiphase Flow and Mixing Phenomena in a Gas-Stirred Ladle: The Effect of Bubble Expansion. JOM 70, 2071–2081 (2018). https://doi.org/10.1007/s11837-018-2977-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-2977-y