Abstract

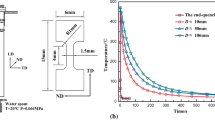

The Jominy end-quench (JEQ) test was adopted to investigate the quench sensitivity of Al-6.6Zn-1.8Mg-0.23Cu-0.22Mn-0.21Zr (7046A) alloy. The mechanical properties of the aged alloy were studied by means of a hardness and tensile property test, whereas microstructure observation was realized by x-ray diffraction (XRD) and transmission electron microscopy (TEM). The results show the following: (I) inhomogeneity exists in the mechanical properties of as-aged alloy and they generally decrease with the distance from the quenched end of the bar (D) where the depth of losing 10% of maximum hardness is 196 mm. (II) Average cooling rates decreased with the increase of D. When the critical average cooling rate is about 1 K s−1, 90% of the maximum hardness can be obtained. (III) On the other hand, the influence of Al3Zr dispersoids and Al6Mn dispersoids on the precipitate behavior of MgZn2 was studied, indicating that Al3Zr and Al6Mn were effective heterogeneous precipitates sites in the slow quenching process.

Similar content being viewed by others

References

J.C. Williams and E.A. Starke, Acta Mater. 51, 5775 (2003).

A. Heinz, A. Haszler, C. Keidel, S. Moldenhauer, R. Benedictus, and W.S. Miller, Mater. Sci. Eng. A 280, 102 (2000).

T. Dursun and C. Soutis, Mater. Des. (1980–2015) 56, 862 (2014).

P.A. Rometsch, Y. Zhang, and S. Knight, Trans. Nonferrous Met. Soc. China 24, 2003 (2014).

J. Chen, L. Zhen, S. Yang, W. Shao, and S. Dai, Mater. Sci. Eng. A 500, 34 (2009).

J.S. Robinson, D.A. Tanner, C.E. Truman, A.M. Paradowska, and R.C. Wimpory, Mater. Character. 65, 73 (2012).

Y.-X. Zhang, Y.-P. Yi, S.-Q. Huang, and F. Dong, Mater. Sci. Eng. A 674, 658 (2016).

Y.L. Deng, L. Wan, Y.Y. Zhang, and X.M. Zhang, J. Alloy Compd. 509, 4636 (2011).

L. Lin, Z. Liu, S. Bai, P. Ying, and X. Wang, Mater. Des. 86, 679 (2015).

L. Lin, Z. Liu, S. Bai, Y. Zhou, W. Liu, and Q. Lv, Mater. Sci. Eng. A 682, 640 (2017).

X.M. Zhang, H. Chen, S.D. Liu, W.J. Liu, and F.R. Huang, J. Cent. South Univ. 43, 1656 (2012).

S.D. Liu, X.M. Zhang, M.A. Chen, and J.H. You, Mater. Character. 59, 53 (2008).

I. Westermann, A.L. Haugstad, Y. Langsrud, and K. Marthinsen, Trans. Nonferrous Met. Soc. China 22, 1872 (2012).

H. Wang, Y. Yi, and S. Huang, J. Alloy Compd. 690, 446 (2017).

X. Zhang, W. Liu, S. Liu, and M. Zhou, Mater. Sci. Eng. A 528, 795 (2011).

N.Q. Chinh, J. Lendvai, D.H. Ping, and K. Hono, J. Alloy Compd. 378, 52 (2004).

S. Liu, X. Zhang, J. You, and X. Zhang, Rare Met. Mater. Eng. 36, 607 (2007).

J. Marrow, Ind. Heat. 68, 57 (2001).

B. Nie, P. Liu, and T. Zhou, Mater. Sci. Eng., A 667, 106 (2016).

S. Liu, W. Liu, Y. Zhang, X. Zhang, and Y. Deng, J. Alloy Compd. 507, 53 (2010).

Y.-C. Tzeng, C.-T. Wu, and S.-L. Lee, Mater. Lett. 161, 340 (2015).

L.K. Berg, J. Gjønnes, V. Hansen, X.Z. Li, M. Knutson-Wedel, G. Waterloo, D. Schryvers, and L.R. Wallenberg, Acta Mater. 49, 3443 (2001).

J.D. Robson and P.B. Prangnell, Acta Mater. 49, 599 (2001).

J.W. Evancho and J.T. Staley, Metall. Trans. 5, 43 (1974).

W. Liu, Ph.D. dissertation, Central South University, Changsha, Hunan, China (2012)

D. Godard, P. Archambault, E. Aeby-Gautier, and G. Lapasset, Acta Mater. 50, 2319 (2002).

X. Peng, Y. Li, G. Xu, J. Huang, and Z. Yin, Met. Mater. Int. (2018). https://doi.org/10.1007/s12540-018-0057-z.

Y.A. Chu, B. Moran, G.B. Olson, and A.C.E. Reid, Metall. Mater. Trans. A 31, 1321 (2000).

T. Ogura, S. Hirosawa, A. Cerezo, and T. Sato, Mater. Sci. Forum 519, 431 (2006).

Y. Deng, Z. Yin, J. Duan, K. Zhao, B. Tang, and Z. He, J. Alloy Compd. 517, 118 (2012).

Y. Deng, Z. Yin, K. Zhao, J. Duan, and Z. He, J. Alloy Compd. 530, 71 (2012).

C. Li, S. Wang, D. Zhang, S. Liu, Z. Shan, and X. Zhang, J. Alloy Compd. 688, 456 (2016).

I.S. Golovin, A.S. Bychkov, A.V. Mikhailovskaya, and S.V. Dobatkin, Phys. Met. Metall. 115, 192 (2014).

Acknowledgements

This work was financially supported by the Guangdong Province Scientific and Research Plan Project (2016B090931004), and the authors thank the Guangdong Haomei Aluminum Co., Ltd. providing hot-extrusion 7046A aluminum alloy.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Jiang, F., Huang, J., Tang, L. et al. Effects of Quench Rate on Mechanical Properties and Microstructures of High-Strength 7046A Aluminum Alloy. JOM 71, 1722–1730 (2019). https://doi.org/10.1007/s11837-018-3153-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3153-0