Abstract

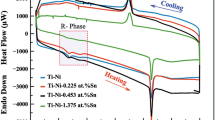

NiTi shape memory alloys (SMAs), as smart materials, are broadly used in medical implants and appliances despite the presence of toxic Ni. In this study, NiTiNb alloys were produced using the substitution of biocompatible Nb instead of Ni. The arc-melting method was utilized to make five SMA samples comprising Ni(29−x)Ti50Nb(21+x) (x = 0, 1, 2, 3, and 4); then, the phase transformation temperatures, microstructures, crystal structures, and chemical compositions were investigated by DSC, optical microscopy, XRD, and EDX measurements, respectively. The DSC results showed that the samples had a wide hysteresis with the B19′↔B2 phase transformation and martensite start temperatures below room temperature, which makes them suitable for superelastic implants. The presence of dissolved Nb in the matrix of the alloys was the main reason for the widening of temperature hysteresis. When the XRD and SEM results were examined, the β-rich, B2, B19′, and Ti2Ni phases were observed in all samples. Additionally, the main constituent in the dendritic microstructures was Nb.

Similar content being viewed by others

References

J.M. Jani, M. Leary, A. Subic, and M.A. Gibson, Mater. Des. 56, 1078 (2014).

I.N. Qader, M. Kök, F. Dağdelen, and Y. Aydogdu, El-Cezerî J. Sci. Eng. 6, 755 (2019).

D. Wield and E. Gillam, Scripta Metall. 6, 1157 (1972).

W.J. Buehler, J. Gilfrich, and R. Wiley, J. Appl. Phys. 34, 1475 (1963).

X. Zhao, J. Xu, L. Tang, and S. Gong, Intermetallics 15, 1105 (2007).

M. Zarinejad, Y. Liu, and Y. Tong, Intermetallics 17, 914 (2009).

K. Nitta, S. Watanabe, N. Masahashi, H. Hosoda, S. Hanada, M. Niinomi, T. Okabe, E. Taleff, D. Lesuer and H. Lippard, Warrendale, Pennsylvania, USA, TMS 25, 34 (2001)

S. Steinemann, Adv. Biomater. 1, 1 (1980).

T. Mousavi, F. Karimzadeh, and M. Abbasi, Mater. Sci. Eng., A 487, 46 (2008).

C. Ying, J. Hai-Chang, R. Li-Jian, X. Li, and Z. Xin-Qing, Intermetallics 19, 217 (2011).

T. Duerig and K. Melton, European Symposium on Martensitic Transformations, 191, EDP Sciences

P. A. Besselink and R. C. Sachdeva Ni-Ti-Nb alloy processing method and articles formed from the alloy, Google Patents, (2002)

C. A. Aloise and G. T. Garman Method of manufacturing an endodontic instrument, Google Patents (2007)

J.M. de Alcântara Abdala, B.B. Fernandes, D.R. Dos Santos, V.A.R. Henriques, Neto C. de Moura, and A.S. Ramos, J. Alloys Comp. 495, 423 (2010).

Y. Zhou, C.-J. Li, G.-J. Yang, H.-D. Wang, and G. Li, Intermetallics 18, 2154 (2010).

X. He, L. Rong, D. Yan, and Y. Li, Scripta Mater. 53, 1411 (2005).

Y. Chen, H. Jiang, S. Liu, L. Rong, and X. Zhao, Mater. Sci. Eng., A 512, 26 (2009).

X. Fu, M. Guojun, Z. Xinqing, and X. Huibin, Chin. J. Aeronaut. 22, 658 (2009).

K. Otsuka and X. Ren, Progr. Mater. Sci. 50, 511 (2005).

K. Melton and O. Mercier, Acta Metall. 29, 393 (1981).

E. Choi, Y.-S. Chung, Y.-W. Kim, and J.-W. Kim, Smart Mater. Struct. 20, 075016 (2011).

X. Zhao, X. Yan, Y. Yang, and H. Xu, Mater. Sci. Eng., A 438, 575 (2006).

K. Melton, J. Proft and T. Duerig, Proceedings of the MRS International Meeting on Advanced Materials., 165,

E. Choi, Y.-S. Chung, J.-H. Choi, H.-T. Kim, and H. Lee, Smart Mater. Struct. 19, 035024 (2010).

M. Kök, H.S.A. Zardawi, I.N. Qader, and M.S. Kanca, Eur. Phys. J. Plus 134, 197 (2019).

B.V. Krishna, S. Bose, and A. Bandyopadhyay, Metall. Mater. Trans. A 38, 1096 (2007).

F. Dagdelen and Y. Aydogdu, J. Therm. Anal. Calorim. 136, 637 (2019).

I.N. Qader, M. Kök, and F. Dağdelen, Physica B: Condens. Matter. 553, 1 (2019).

F. Dagdelen, M. Kok and I. Qader, Metals Mater. Int., 1 (2019).

E. Ercan, F. Dagdelen and I. Qader, J. Therm. Anal. Calorim., 1 (2019).

M. Kok, A. O. A. Al-Jaf, Z. D. Çirak, I. N. Qader and E. Özen, J. Therm. Anal. Calorim. (2019).

M. Kök, I. N. Qader, S. S. Mohammed, E. ÖNER, F. Dağdelen and Y. Aydogdu, Mater. Res. Express 7 (2020).

K. Nurveren, A. Akdoğan, and W. Huang, J. Mater. Process. Technol. 196, 129 (2008).

J. W. Christian, The Theory of Transformations in Metals and Alloys, Newnes (2002).

G. Fan, W. Chen, S. Yang, J. Zhu, X. Ren, and K. Otsuka, Acta Mater. 52, 4351 (2004).

K. Li, Y. Li, K. Yu, C. Liu, D. Gibson, A. Leyland, A. Matthews, and Y.Q. Fu, Appl. Phys. Lett. 108, 171907 (2016).

R. Zhu, G. Tang, S. Shi, and M. Fu, J. Mater. Process. Technol. 213, 30 (2013).

T. Tabish, N. Alia, A. Aslama, N. Abbasa, S. Gashkoria, and T. Buttb, Turk. J. Eng. 2, 90 (2014).

G. Sun, X. Wang, Y. Wang, W. Woo, H. Wang, X. Liu, B. Chen, Y.Q. Fu, L. Sheng, and Y. Ren, Mater. Sci. Eng., A 560, 458 (2013).

M. Piao, S. Miyazaki, K. Otsuka and N. Nishida, Mater. Trans., JIM 33, 337 (1992).

X. Zhou, Y. Chen, Y. Huang, Y. Mao, and Y. Yu, J. Alloys Comp. 735, 2616 (2018).

J. Li, H. Wang, J. Liu, and J. Ruan, Mater. Sci. Eng., A 609, 235 (2014).

X. He, L. Rong, D. Yan, and Y. Li, Mater. Sci. Eng., A 371, 193 (2004).

C. Wang, Q. Gao, Y. Yuan, H. Zhang, J. Zhang, Q. Wang, and F. Qu, J. Alloys Compd. 695, 2923 (2017).

H. Yin, G. Ma, Q. Fan, Y. Wang, S. Huang, and Y. Yi, Metals 9, 214 (2019).

C. Bewerse, L.C. Brinson, and D.C. Dunand, Mater. Sci. Eng., A 627, 360 (2015).

Acknowledgements

This work is supported by Firat University Research Project Unit under project no. FF.18.30.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dagdelen, F., Balci, E., Qader, I.N. et al. Influence of the Nb Content on the Microstructure and Phase Transformation Properties of NiTiNb Shape Memory Alloys. JOM 72, 1664–1672 (2020). https://doi.org/10.1007/s11837-020-04026-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04026-6