Abstract

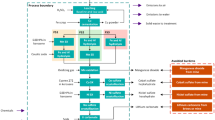

A new process is presented for low-cost one-step production of pure solid silicon from natural quartzite by molten salt electrolysis. At a process temperature of 1100°C, a techno-economic model including detailed mass and energy balances estimates energy consumption below 15 kWh/kg, with operating cost of $1.74/kg and capital cost around $10,500 per t/a (tonne annually) of production capacity for a 160,000 t/a plant. Use of an inert solid oxide membrane anode results in a pure oxygen by-product and no direct emissions. Finite element analysis estimates the current density distribution and total current to inform the design of slab-shaped solid silicon cathodes.

Similar content being viewed by others

References

S.A. Mann, M.J. de Wild-Scholten, V.M. Fthenakis, W.G.J.H.M. van Sark, and W.C. Sinke, Prog. Photovolt. Res. Appl. 22, 1180 (2014).

M. Osborne, “Explosion at Mitsubishi polysilicon plant in Japan causes deaths” PV Tech (2014). https://www.pv-tech.org/news/explosion_at_mitsubishi_polysilicon_plant_in_japan_causes_deaths. Accessed July 2020

M. Pace, “Final investigation determines Wacker explosion out of company's control” Chatt. Times Free Press (2018). https://www.timesfreepress.com/news/breakingnews/story/2018/jul/05/final-investigation-wacker-explosion/474431/. Accessed July, 2020

n.a. “Polysilicon Shortage: Production Solar panels in Danger” BetterWorldSolutions—Neth. (2018). https://www.betterworldsolutions.eu/rawmaterial-shortage-production-solar-panels-danger/. Accessed July 2020

T. Buonassisi, A.A. Istratov, M.A. Marcus, B. Lai, Z. Cai, S.M. Heald, and E.R. Weber, Nat. Mater. 4, 676 (2005).

W.O. Filtvedt, M. Javidi, A. Holt, M.C. Melaaen, E. Marstein, H. Tathgar, and P.A. Ramachandran, Sol. Energy Mater. Sol. Cells 94, 1980 (2010).

A. Ramos, W.O. Filtvedt, D. Lindholm, P.A. Ramachandran, A. Rodríguez, and C. del Cañizo, J. Cryst. Growth 431, 1 (2015).

S. Nichol, U.S. Patent 7,727,503 (1 June 2010)

Y. Ren, S. Ueda, and K. Morita, A.C.S. Sustain. Chem. Eng. 7, 20107 (2019).

L.A.V. Teixeira and K. Morita, ISIJ Int. 49, 783 (2009).

K. Morita and T. Yoshikawa, Trans. Nonferrous Met. Soc. China 21, 685 (2011).

E. Olsen and S. Rolseth, Metall. Mater. Trans. B 41, 295 (2010).

Y.-Q. Lai, M. Jia, Z.-L. Tian, J. Li, J.-F. Yan, J.-G. Yi, Z.-G. Wang, and Y.-X. Liu, Metall. Mater. Trans. A 41, 929 (2010).

K. Johansen, D.R. Sadoway, B. Myhre, M. Engvoll, and K. Engvoll, 7,901,561 (8 March 2011)

G.M. Haarberg, in TMS Middle East - Mediterr. Mater. Congr. Energy Infrastruct. Syst. MEMA 2015 (TMS, 2015), p. 6

T. Nohira, in Encycl. Appl. Electrochem., edited by G. Kreysa, K. Ota, and R. F. Savinell (Springer New York, New York, NY, 2014), pp. 1963–1966

E. Juzeliunas and D.J. Fray, Chem. Rev. 120, 1690 (2020)

K. Yasuda, T. Nohira, K. Amezawa, Y.H. Ogata, and Y. Ito, J. Electrochem. Soc. 152, D69 (2005).

X. Jin, P. Gao, D. Wang, X. Hu, and G.Z. Chen, Angew. Chem. Int. Ed. 43, 733 (2004).

U. Cohen, J. Electron. Mater. 6, 607 (1977).

D. Elwell and G.M. Rao, J. Appl. Electrochem. 18, 15 (1988).

J.T. Moore, T.H. Wang, M.J. Heben, K. Douglas, and T.F. Ciszek, in Conf. Rec. Twenty Sixth IEEE Photovolt. Spec. Conf.—1997 (IEEE, Anaheim, CA, USA, 1997), pp. 775–778

K. Grjotheim, K. Matiaśovský, P. Fellner, and A. Silný, Can. Metall. Q. 10, 79 (1971).

T. Oishi, M. Watanabe, K. Koyama, M. Tanaka, and K. Saegusa, J. Electrochem. Soc. 158, E93 (2011).

G. Bøe, K. Grjotheim, K. Matiašovský, and P. Fellner, Can. Metall. Q. 10, 281 (1971).

G. Bøe, K. Grjotheim, K. Matiašovský, and P. Fellner, Can. Metall. Q. 11, 463 (1972).

G.M. Haarberg, T. Kato, Y. Norikawa, and T. Nohira, ECS Trans. 89, 29 (2019).

Y. Ma, A. Ido, K. Yasuda, R. Hagiwara, T. Homma, and T. Nohira, J. Electrochem. Soc. 166, D162 (2019).

J. Xu, B. Lo, Y. Jiang, U. Pal, and S. Basu, J. Eur. Ceram. Soc. 34, 3887 (2014).

J. Guo, T. Villalon, U. Pal, and S. Basu, J. Am. Ceram. Soc. 101, 3605 (2018).

T. Villalón Jr., Zero-Direct Emission Silicon Production via Solid Oxide Membrane Electrolysis (Ph.D.: Boston University, 2018).

U.B. Pal, D.E. Woolley, and G.B. Kenney, JOM 53, 32 (2001).

U.B. Pal and A.C. Powell, JOM 59, 44 (2007).

X. Ma, T. Yoshikawa, and K. Morita, J. Cryst. Growth 377, 192 (2013).

A.C. Powell and S.J. Derezinski, U.S. Patent 8,460,535 (11 June 2013)

D. Matuszak, ARPA-E METALS Tool (Department of Energy: U.S, 2013).

K.I. Vatalis, G. Charalambides, and N.P. Benetis, Procedia Econ. Finance 24, 734 (2015).

A. Powell and S. Pati, in CFD Model. Simul. Mater. Process., edited by L. Nastac, L. Zhang, B.G. Thomas, A. Sabau, N. El-Kaddah, A.C. Powell, and H. Combeau (John Wiley & Sons, Inc., Hoboken, NJ, USA, 2012), pp. 57–64

M.W. Chase, NIST-JANAF Thermochemical Tables, 4th ed. (National Institute of Technology, Gaithersburg, Maryland, USA, 1996)

A. Krishnan, Solid Oxide Membrane Process for the Direct Reduction of Magnesium from Magnesium Oxide (Ph.D.: Boston University, 2006).

Z.R. Hesabi, M. Mazaheri, and T. Ebadzadeh, J. Alloys Compd. 494, 362 (2010).

C. Stinn and A. Allanore, Electrochem. Soc. Interface 29, 44 (2020).

C. Ritter, Interview regarding operation and economics of Century Aluminum’s Goose Creek smelter (2020).

A. Cezairliyan and A.P. Miiller, Int. J. Thermophys. 4, 389 (1983).

M.C.H.M. Wouters, H.M. Eijkman, and L.J. van Ruyven, Philips Res. Repts. 31, 278 (1976).

S. Fan, G. Plascencia, and T. Utigard, Can. Metall. Q. 47, 509 (2008).

D.E. Holcomb and S.M. Cetiner, An Overview of Liquid-Fluoride-Salt Heat Transport Systems (Oak Ridge National Laboratory, 2010)

Acknowledgments

This material is based upon work supported by the US Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE) under the Solar Energy Technologies Office Award No. DE-EE0008988 and by the US National Science Foundation under Award Nos. 1937818 and 1829089. This research was performed using computational resources supported by the Academic and Research Computing group at Worcester Polytechnic Institute.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Moudgal, A., Buasai, S., Wu, Y.J. et al. Finite Element Analysis and Techno-economic Modeling of Solar Silicon Molten Salt Electrolysis. JOM 73, 233–243 (2021). https://doi.org/10.1007/s11837-020-04468-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04468-y