Abstract

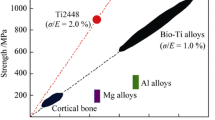

Titanium alloys composed of nontoxic elements are being studied in Japan for use in biomedical applications. The alloys being studied are primarily α + ß- and ß-type titanium alloys. Areas of research include surface treatments to improve biocompatibility and methods of preventing fretting fatigue, a primary cause of failure in biomaterials.

Similar content being viewed by others

References

S.G. Steinemann, “Corrosion of Surgical Implants—in Vivo and in Vitro Tests,” Evaluation of Biomaterials, ed. G.D. Winter, J.L. Leray, and K. de Groot (New York: Wiley, 1980), pp. 1–34.

H. Kawahara, “Cytotoxicity of Implantable Metals and Alloys,” Bull Japan Inst. Metals, 31 (12) (1992), pp. 1033–1039.

N. Yukawa et al., “Alloy Design of Superalloys by the delectron Concept,” Proc. High Temperature Alloys for Gas Turbines and Other Applications (Belgium: Commission of European Communities, 1986), pp. 1–9.

M. Morinaga, N. Yukawa, and H. Adachi, “Electronic Structure and Phase Stability of Titanium Alloys,” J. Iron and Steel Inst. Japan, 72 (6) (1986), pp. 555–562.

Y. Ito et al., “New Titanium Alloys for Medical Implants,” Proc. Titanium ′95: Science and Technology, ed. P.A. Blenkinsop, W.J. Evans, and H.M. Flower (London: IOM, 1995), pp. 776–1783.

Y. Okazaki et al., “Mechanical Properties and Corrosion Fatigue of New Titanium Alloys for Medical Implants in Physiological Saline Solution,” J. Japan Inst. Metals, 59 (10) (1995), pp. 1078–1085.

M. Niinomi et al., “New ß-Type Titanium Alloys with High Biocompatibility,” Non-Aerospace Applications of Titamium, ed. F.H. Froes, P.G. Allen, and M. Niinomi (Warrendale, PA: TMS, 1998), pp. 217–223.

S. Yoshitani et al., “Mechanical Properties of ß-Type Alloys with High Biocompatibility Fabricated by Powder Metallurgy Processing,” CAMP, ISIJ, 12 (1) (1999), p. 540.

E. Kobayashi et al., “Evaluation of Mechanical Properties of Dental Casting Ti-Zr Based Alloys,” J. Japanese Soc. Dental Materials and Devices, 14 (3) (1995), pp. 321–328.

E. Kobayashi et al., “Alloy—Design of Titanium-Zironium Based Alloys Containing Niobium as Biomedical Materials,” Proc. Fifth World Biomaterials Congress (Toronto, Canada: Univ. of Toronto Press, 1996), pp. 481–482.

E. Kobayashi et al., “Castability and Mechanical Properties of Ti-6Al-7Nb Alloy Dental-Cast,” J. Japanese Soc. Dental Materials and Devices, 14 (4), (1995), pp. 406–413.

K. Kato et al., “On the Adhesiveness between Ti-40wt%Zr Alloy and the Thermosetting Facing Resin,” J. Japanese Soc. Dental Materials and Devices, Special Issue 33, 18 (1999), p. 121.

H. Hamanaka et al., “Corrosion Resistance and Mechanical Properties of Cast Ti-5Al-13Ta Alloys,” J. Japanese Soc. Dental Materials and Devices, Special Issue 31, 17 (1998), p. 88.

K. Narita et al., “Fracture Toughness Characteristic of Cast Pure Titanium and Titanium Alloy,” J. Japanese Soc. Dental Materials and Devices, Special Issue 31, 17 (1998), p. 90.

E. Kobayashi et al., “Structure Control of Ti-Zr Biomedical Implant Alloys,” J. Japanese Soc. Dental Materials and Devices, Special Issue 26 (1995), pp. 78–79.

T. Hanawa, “Surface Modification of Metallic Bio-materials,” Materia Japan, 37 (19) (1988), pp. 853–855.

M. Yoshinari, K. Ozeki, and T. Sumii, “Properties of Hydroxyapatite-Coated Ti-6Al-4V Alloy Produced by the Ion-Plating Method,” Bull. Tokyo Dent. Coll., 32 (1991), pp. 147–156.

M. Yoshinari et al., “Influence of Rapid Heating with Infrared Radiation on RF Magnetron Sputtered Calcium Phosphate Coatings,” J. Biomed. Mater. Res., 37 (1997), pp. 60–67.

T. Kasuga and Y. Abe, “Calcium Phosphate Invert Glasses with Soda and Titania,” J. Non-Crystalline Solids, 243 (1999), pp. 70–74.

H.-M. Kim et al., J. Biome. Mater. Res., 34 (1996), p. 409.

T. Hanawa et al., “Surface Modification of Titanium in Calcium-Ion-Containing Solutions,” J. Biomed Mater. Res., 34 (1997), p. 273.

T. Hanawa, S. Kihara, and K. Murakami, ASTM STP 1196 (1994), pp. 170–184.

S. Fukumoto et al., Abstract Booklet of Xi’an Int. Titanium Conf. (1998), p. 84.

N. Maruyama, T. Kobayashi, and M. Sumita, “Fretting Fatigue Strength of a Ti-6Al-4V Alloy in a Pseudo-Body-Fluid and Quantitative Analyses of the Substances in the Fluids,” J. Japanese Soc. Biomaterials, 13 (1) (1995), pp. 14–20.

Author information

Authors and Affiliations

Additional information

Author’s Note: All compositions are given in mass percent unless otherwise noted.

For more information, contact M. Niinomi, Toyohashi University of Technology, 1-1 Hibarigaoka, Tempaku-cho, Toyohashi 441-8580, Japan; telephone 81532-44-6706; fax 81-532-44-6690; e-mail niinomi@sp-Mac4.tutpse.tut.ac.jp.

Rights and permissions

About this article

Cite this article

Niinomi, M. Recent titanium R&D for biomedical applications in japan. JOM 51, 32–34 (1999). https://doi.org/10.1007/s11837-999-0091-x

Issue Date:

DOI: https://doi.org/10.1007/s11837-999-0091-x