Abstract

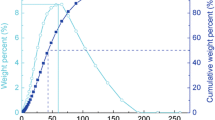

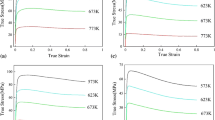

The microstructural evolution and mechanical properties of a hypereutectic Al-Si alloy processed by liquid die forging were investigated. It is found that the grain size of the primary Si was significantly reduced by liquid die forging with increased pressure. The volume fraction of eutectic silicon was decreased with increased pressure. By liquid die forging with pressure up to 180 MPa, the average size of the primary Si was reduced to about 18 μm, which results in the remarkable increase in the fracture strength and hardness of the hypereutectic Al-Si alloy.

Similar content being viewed by others

References

Begg J 1992 Process optimization in the squeeze casting of zinc-aluminum alloys and composites (UK: Loughborough University of Technology)

Brazhkina V V, Popov S V, Voloshina R N, Stanev L M and Spirov I G 1991 High Press. Res. 6 333

Chang J Y, Moon I and Choi C S 1998 J. Mater. Sci. 33 5015

Chen Z W, Jie W Q and Zhang R J 2005 Mater. Lett. 599 2183

Choi H S, Konishi H and Li X C 2012 Mater. Sci. Eng. A541 159

Choi H S and Li X C 2012 J. Mater. Sci. 47 3096

Dahle A K, Nogita K, McDonald S D, Dinnis C and Lu L 2005 Mater. Sci. Eng. A413–414 243

Hekmat-Ardakan A and Ajersch F 2010 Acta Mater. 58 3422

Hekmat-Ardakan A, Liu X C, Ajersch F and Chen X G 2010 Wear 269 684

Hong S Z and Zeng Z P 2002 Spec. Cast. Nonferr. Alloys 22 26

Jung H K, Seo P K and Kang C G 2001 J. Mater. Process. Technol. 113 568

Kilicaslana M F, Lee W R, Lee T H, Sohn Y H and Hong S J 2012 Mater. Lett. 71 164

Li B, Wang H W, Jie J C and Wei Z J 2011a Mater. Des. 32 1617

Li B, Wang H W, Jie J C and Wei Z J 2011b J. Alloys Compd. 509 3387

Li L X, Zong H T, Li M, Wang H X and Cai H X 2012 High Temp.-High Pres. 41 69

Liu G, Li G D, Cai A H and Chen Z K 2011 Mater. Des. 32 121

Lu D H, Jiang Y H, Guan G S, Zhou R F, Li Z H and Zhou R 2007 J. Mater. Process. Technol. 189 13

Lu L, Nogita K and Dahle A K 2005 Mater. Sci. Eng. A399 244

Mayers M A and Chawla K K 1999 Mechanical behaviour of materials (Upper Saddle River, New Jersey: Prentice Hall)

McDonald S D, Nogita K and Dahle A K 2004 Acta Mater. 52 4273

Mohamed A M A, Samuel A M, Samuel F H and Doty H W 2009 Mater. Des. 30 3943

Murali S and Yong M S 2010 J. Mater. Process. Technol. 210 1276

Nogita K, Yasuda H, Yoshida M, McDonald S D, Uesugi K, Takeuchi A and Suzuki Y 2010 J. Alloys Compd. 489 415

Prukkanona W, Srisukhumbowornchai N and Limmaneevichitr C 2009 J. Alloys Compd. 477 454

Sha M, Wu S S, Wang X T, Wan L and Ping A 2012 Mater. Sci. Eng. A535 258

Song K K, Bian X F, Guo J, Wang S H, Sun B A, Li X L and Wang C D 2007 J. Alloys Compd. 440 L8

Srirangam P, Kramer M J and Shankar S 2011 Acta Mater. 59 503

Tsai Y C, Chou C Y, Lee S L, Lin C K, Lin J C and Lim S W 2009 J. Alloys Compd. 487 157

Uzun O, Karaaslan T, Gogebakan M and Keskin M 2004 J. Alloys Compd. 376 149

Voncina M, Kores S, Mrvar P and Medved J 2011 J. Alloys Compd. 509 7349

Wang E D, Hui X D, Wang S S, Zhao Y F and Chen G L 2011 Mater. Sci. Eng. A528 5764

Wang Y P, Wang S J, Li H and Liu X F 2009 J. Alloys Compd. 477 139

Wu H and Chin B A 1991 J. Mater. Sci. 26 993

Xing P F, Gao B, Zhuang Y X, Liu K H and Tu G F 2010a J. Rare Earths 28 927

Xing P F, Gao B, Zhuang Y X, Liu K H and Tu G F 2010b Acta Metall. Sin. 23 327

Xu C L, Wang H Y, Yang Y F and Jiang Q C 2007 Mater. Sci. Eng. A452–453 341

Yi H K and Zhang D 2003 Mater. Lett. 57 2523

Yu X F, Zhang G Z, Wang X Y, Gao Y Y, Jia G L and Hao Z Y 1999 J. Mater. Sci. 34 4149

Yu X F, Zhang G Z, Xiao H J, Pan A S, Jia G L, Gao Y Y, Hao Z Y and Guo X B 2000 Chin. J. Mater. Res. 14 141

Zhang H H, Duan H L, Shao G J, Xu L P, Yin J L and Yan B 2006 Rare Metals 25 11

Zhou J and Duszczyk J 1990 J. Mater. Sci. 25 4541

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, F.F., Li, S.T., Zhang, G.A. et al. Microstructural evolution and mechanical properties of hypereutectic Al-Si alloy processed by liquid die forging. Bull Mater Sci 37, 1153–1157 (2014). https://doi.org/10.1007/s12034-014-0056-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-014-0056-8