Abstract

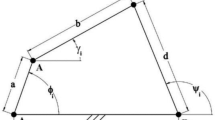

This paper proposes a structural design and multi-objective optimization of a two-degree-of-freedom (DOF) monolithic mechanism. The mechanism is designed based on compliant mechanism with flexure hinge and is compact in size (126 mm by 107 mm). Unlike traditional one-lever mechanisms, a new double-lever mechanism is developed to increase the working travel amplification ratio of the monolithic mechanism. The ideal amplification ratio, the working travel, the statics and the dynamics of the mechanism are taken into consideration. The effects of design variables on the output responses such as the displacement and first natural frequency are investigated via finite-element analysis based on response surface methodology. The fuzzy-logic-based Taguchi method is then used to simultaneously optimize the displacement and the first natural frequency. Experimental validations are conducted to verify the optimal results, which are compared to those of the original design. On using a finite-element method, the validation results indicated that the displacement and frequency are enhanced by up to 12.47% and 33.27%, respectively, over those of the original design. The experiment results are in a good agreement with the simulations. It also revealed that the developed fuzzy-logic-based Taguchi method is an effectively systematic reasoning approach for optimizing the multiple quality characteristics of compliant mechanisms. It was noted that the working travel/displacement of the double-lever mechanism is much larger than that of the traditional one-lever mechanism. It leads to the conclusion that the proposed mechanism has good performances for manipulations and positioning systems.

Similar content being viewed by others

References

Li Y and Xu Q 2009 Design and analysis of a totally decoupled flexure-based XY parallel micromanipulator. IEEE Trans. Robot. 25: 645–657

Li Y and Xu Q 2011 A novel piezoactuated XY stage with parallel, decoupled, and stacked flexure structure for micro-/nanopositioning. IEEE Trans. Ind. Electron. 58: 3601–3615

Li Y, Huang J and Tang H 2012 A compliant parallel XY micromotion stage with complete kinematic decoupling. IEEE Trans. Autom. Sci. Eng. 9: 538–553

Howell L L 2001 Compliant mechanisms. New York: Wiley

Lai L, Gu G Y, Li P and Zhu L M 2011 Design of a decoupled 2-DOF translational parallel micro-positioning stage. In: Proceedings of the IEEE International Conference on Robotics and Automation, Shanghai International Conference Center, pp. 5070–5075

Xiao S and Li Y 2013 Optimal design, fabrication and control of an XY micro-positioning stage driven by electromagnetic actuators. IEEE Trans. Ind. Electron. 60: 4613–4623

Xu Q S 2014 Design and development of a compact flexure-based XY precision positioning system with centimeter range. IEEE Trans. Ind. Electron. 61(2): 893–903

Philipp J T, Kimberly L T and Paul K H 2007 Design and modeling of a high-speed AFM-scanner. IEEE Trans. Control Syst. Technol. 15(5): 906–915

Tang H and Li Y 2013 Design, analysis, and test of a novel 2-DOF nanopositioning system driven by dual mode. IEEE Trans. Robot. 29(3): 650–662

Dao T P and Huang S C 2013 Design and analysis of compliant rotary joint. Appl. Mech. Mater. 372: 467–470

Dao T P and Huang S C 2015a Robust design for a flexible bearing with 1-DOF translation using the Taguchi method and the utility concept. J. Mech. Sci. Technol. 29(8): 3309–3320

Dao T P and Huang S C 2015b Design, fabrication, and predictive model of a 1-DOF translational, flexible bearing for high precision mechanism. Trans. Can. Soc. Mech. Eng. 39(3): 419–429

ANSYS 2013 ANSYS workbench user’s guide. Canonsburg, PA, USA: ANSYS

Fnides B, Yallese M A, Mabrouki T and Rigal J F 2011 Application of response surface methodology for determining cutting force model in turning hardened AISI H11 hot work tool steel. Sadhana 36: 109–123

Hari S and Pradeep K 2006 Optimizing feed force for turned parts through the Taguchi technique. Sadhana 31: 671–681

Wierman M J 2008 Fuzzy sets. Fuzzy logic and control. In: An introduction to the mathematics of uncertainty. Omaha, Nebraska: Center of Mathematics of Uncertainty, Creighton University

Klir G J and Yuan B 2005 Fuzzy sets and fuzzy logic: theory and applications, 3rd ed. New Delhi: Prentice Hall of India

Mamdani E H and Assilian S 1975 An experiment in linguistic synthesis with a fuzzy logic controller. Int. J. Man–Mach. Stud. 7: 1–13

Acknowledgements

The authors acknowledge and thank the Ministry of Science and Technology of the Republic of China for their financial support of this study under Contract Number MOST 103-2221-E-151-035.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dao, TP., Huang, SC. Design and multi-objective optimization for a broad self-amplified 2-DOF monolithic mechanism. Sādhanā 42, 1527–1542 (2017). https://doi.org/10.1007/s12046-017-0714-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12046-017-0714-9