Abstract

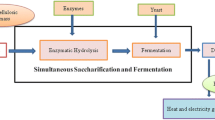

Lignocellulosic biomass is one of the most abundant raw materials in the world, and it is mainly composed of carbohydrate polymers (cellulose and hemicellulose) and lignin. Its applications vary from the production of pulp and paper, to the most recent plant-based bioethanol production, which has challenge due to low hydrolysis conversion rates by the inherit recalcitrance of biomass. The biomass is naturally resistant due the high complexity in the component organization and interaction in the cell wall. The application of pretreatment technologies is one of the most used strategies to overcome biomass recalcitrance. These techniques often require a catalyst to modify the lignocellulosic structure which can be acids, alkaline compounds, ionic solutions, organic solvents, and even pressurized steam among others. The type of catalyst dictates the name of the pretreatment involved. This work presents an overview of these strategies, along with some recent contributions from the scientific community to improve biomass conversion technologies. The discussion is focused on the key factors related to the recalcitrance and conversion process, as well as the composition and physicochemical properties.

Similar content being viewed by others

References

Zhao X, Zhang L, Liu D (2012) Biomass recalcitrance. Part I: the chemical compositions and physical structures affecting the enzymatic hydrolysis of lignocellulose. Biofuels Bioprod Biorefin 6(4):465–482

Kamm B, & Kamm M. (2007). Biorefineries–multi product processes. In White Biotechnology (pp. 175-204). Springer Berlin Heidelberg

Jørgensen H, Kristensen JB, Felby C (2007) Enzymatic conversion of lignocellulose into fermentable sugars: challenges and opportunities. Biofuels Bioprod Biorefin 1(2):119–134

Brienzo M, Abud Y, Ferreira S, Corrales RC, Ferreira-Leitão VS, de Souza W, & Sant’Anna C (2016). Characterization of anatomy, lignin distribution, and response to pretreatments of sugarcane culm node and internode. Ind Crop Prod, 84, 305–313

Chang VS, & Holtzapple MT (2000). Fundamental factors affecting biomass enzymatic reactivity. In Twenty-first symposium on biotechnology for fuels and chemicals (pp. 5-37). Humana Press, Totowa

Zheng Y, Pan Z, Zhang R (2009) Overview of biomass pretreatment for cellulosic ethanol production. Int J Agric Biol Eng 2(3):51–68

Brienzo M, Fikizolo S, Benjamin Y, Tyhoda L, Görgens J (2017) Influence of pretreatment severity on structural changes, lignin content and enzymatic hydrolysis of sugarcane bagasse samples. Renew Energy 104:271–280

Gámez S, González-Cabriales JJ, Ramírez JA, Garrote G, Vázquez M (2006) Study of the hydrolysis of sugar cane bagasse using phosphoric acid. J Food Eng 74(1):78–88

Rodrıguez-Chong A, Ramı́rez JA, Garrote G, Vázquez M (2004) Hydrolysis of sugar cane bagasse using nitric acid: a kinetic assessment. J Food Eng 61(2):143–152

Cheng KK, Cai BY, Zhang JA, Ling HZ, Zhou YJ, Ge JP, Xu JM (2008) Sugarcane bagasse hemicellulose hydrolysate for ethanol production by acid recovery process. Biochem Eng J 38(1):105–109

Hernández-Salas JM, Villa-Ramírez MS, Veloz-Rendón JS, Rivera-Hernández KN, González-César RA, Plascencia-Espinosa MA, Trejo-Estrada SR (2009) Comparative hydrolysis and fermentation of sugarcane and agave bagasse. Bioresour Technol 100(3):1238–1245

Martín C, Galbe M, Nilvebrant NO, & Jönsson LJ (2002). Comparison of the fermentability of enzymatic hydrolyzates of sugarcane bagasse pretreated by steam explosion using different impregnating agents. In Biotechnology for Fuels and Chemicals (pp. 699-716). Humana Press, Totowa, NJ

Sendelius J (2005). Steam pretreatment optimisation for sugarcane bagasse in bioethanol production. Master of Science Thesis. Department of Chemical Engineering, Lund University, Sweden

Li X, Kondo R, & Sakai K (2002). In vivo and in vitro biobleaching of unbleached hardwood kraft pulp by a marine fungus, Phlebia sp. MG-60. In Progress in Biotechnology (Vol. 21, pp. 185-191). Elsevier

Camassola M, Dillon AJ (2009) Biological pretreatment of sugar cane bagasse for the production of cellulases and xylanases by Penicillium echinulatum. Ind Crop Prod 29(2–3):642–647

Martin C, Klinke HB, Thomsen AB (2007) Wet oxidation as a pretreatment method for enhancing the enzymatic convertibility of sugarcane bagasse. Enzym Microb Technol 40(3):426–432

Pasquini D, Pimenta MT, Ferreira LH, Curvelo AA (2005) Sugar cane bagasse pulping using supercritical CO2 associated with co-solvent 1-butanol/water. J Supercrit Fluids 34(2):125–131

Pereira AA, Martins GF, Antunes PA, Conrrado R, Pasquini D, Job AE et al (2007) Lignin from sugar cane bagasse: extraction, fabrication of nanostructured films, and application. Langmuir 23(12):6652–6659

Tu Q, Fu S, Zhan H, Chai X, Lucia LA (2008) Kinetic modeling of formic acid pulping of bagasse. J Agric Food Chem 56(9):3097–3101

Laser M, Schulman D, Allen SG, Lichwa J, Antal MJ Jr, Lynd LR (2002) A comparison of liquid hot water and steam pretreatments of sugar cane bagasse for bioconversion to ethanol. Bioresour Technol 81(1):33–44

Kurakake M, Kisaka W, Ouchi K, Komaki T (2001) Pretreatment with ammonia water for enzymatic hydrolysis of corn husk, bagasse, and switchgrass. Appl Biochem Biotechnol 90(3):251–259

Li BZ, Balan V, Yuan YJ, Dale BE (2010) Process optimization to convert forage and sweet sorghum bagasse to ethanol based on ammonia fiber expansion (AFEX) pretreatment. Bioresour Technol 101(4):1285–1292

Shoda Y, Nakamoto A, Goto M, Tokuhara W, Noritake Y, Katahira S et al (2012) Short time ionic liquids pretreatment on lignocellulosic biomass to enhance enzymatic saccharification. Bioresour Technol 103(1):446–452

Himmel ME, Ding SY, Johnson DK, Adney WS, Nimlos MR, Brady JW & Foust TD (20/07). Biomass recalcitrance: engineering plants and enzymes for biofuels production. Science, 315(5813), 804–807

K Sheth (2017). Top Sugarcane Producing Countries. http://www.worldatlas.com/articles/top-sugarcane-producing-countries.html. Accessed 20 December 2017;

Hussain, A., Khan, Z. I., Ghafoor, M. Y., & Ashraf, M. (2004). Review Sugarcane, Sugar Metabolism and Some Abiotic Stresses

Smith DM, Inman-Bamber NG, Thorburn PJ (2005) Growth and function of the sugarcane root system. Field Crop Res 92(2–3):169–183

Sanjuan R, Anzaldo J, Vargas J, Turrado J, Patt R (2001) Morphological and chemical composition of pith and fibers from Mexican sugarcane bagasse. Holz als Roh-und Werkstoff 59(6):447–450

Miller JD, Gilbert RA, & Odero DC (2009). Sugarcane botany: a brief view. University of Flórida, IFAS Extension

Sun RC, Fang JM, Tomkinson J, Geng ZC, Liu JC (2001) Fractional isolation, physico-chemical characterization and homogeneous esterification of hemicelluloses from fast-growing poplar wood. Carbohydr Polym 44(1):29–39

Brienzo M, Ferreira S, Vicentim MP, de Souza W, & Sant’Anna C (2014). Comparison study on the biomass recalcitrance of different tissue fractions of sugarcane culm. BioEnergy Res, 7(4), 1454–1465

Costa TH, Masarin F, Bonifácio TO, Milagres AM, Ferraz A (2013) The enzymatic recalcitrance of internodes of sugar cane hybrids with contrasting lignin contents. Ind Crop Prod 51:202–211

Cerqueira DA, Rodrigues Filho G, da Silva Meireles C (2007) Optimization of sugarcane bagasse cellulose acetylation. Carbohydr Polym 69(3):579–582

Adsul MG, Ghule JE, Singh R, Shaikh H, Bastawde KB, Gokhale DV, Varma AJ (2004) Polysaccharides from bagasse: applications in cellulase and xylanase production. Carbohydr Polym 57(1):67–72

Harris DR, & Hillman GC (Eds.). (2014). Foraging and farming: the evolution of plant exploitation (Vol. 31). Routledge

S Ullmann. Milho. (2001) http://www.ufrgs.br/afeira/materias-primas/cereais/millho. Accessed 20 December 2017

U. S. Department of Agriculture. USDA. (2017). https://www.usda.gov/. Accessed 20 December 2017

Bechoux N, Bernier G, Lejeune P (2000) Environmental effects on the early stages of tassel morphogenesis in maize (Zea mays L.). Plant, Cell Environ 23:91–98

Sridhar Viamajala; Michael J. Selig; Todd B. Vinant; Melvin P. Tucker; Michael E. Himmel; James D. McMillan; Stephen R. Decker Appl Biochem Biotechnol (2006) 130: 509

Hochholdinger, F. (2009). The maize root system: morphology, anatomy, and genetics. In Handbook of maize: its biology (pp. 145-160). Springer, New York, NY

Sylvester, A. W., & Smith, L. G. (2009). Cell biology of maize leaf development. In Handbook of Maize: its biology (pp. 179-203). Springer, New York, NY

Thompson JL, Tyner WE (2014) Corn stover for bioenergy production: cost estimates and farmer supply response. Biomass Bioenergy 62:166–173

Foley KM (1978). Chemical properties, physical properties, and uses of the Anderson’corncob products. The Andersons, Cob Division

Clark TF, & Lathrop EC (1953). Corncobs: their composition, availability, agricultural and industrial Uses. United States Department of Agriculture, Agricultural Research Administration, Bureau of Agricultural and Industrial Chemistry, Northern Regional Research Laboratory

Sokhansanj S, Turhollow A, Cushman J, Cundiff J (2002) Engineering aspects of collecting corn stover for bioenergy. Biomass Bioenergy 23(5):347–355

Chundawat SP, Venkatesh B, Dale BE (2007) Effect of particle size based separation of milled corn stover on AFEX pretreatment and enzymatic digestibility. Biotechnol Bioeng 96(2):219–231

Pu Y, Zhang D, Singh PM, Ragauskas AJ (2008) The new forestry biofuels sector. Biofuels Bioprod Biorefin 2(1):58–73

Atalla RH, Vanderhart DL (1984) Native cellulose: a composite of two distinct crystalline forms. Science 223(4633):283–285

Potters G, Van Goethem D, & Schutte F (2010). Promising biofuel resources: lignocellulose and algae. Nat Educ, 3(9), 14

Bezerra TL, Ragauskas AJ (2016) A review of sugarcane bagasse for second-generation bioethanol and biopower production. Biofuels Bioprod Biorefin 10(5):634–647

Sant’Anna C, De Souza W, & Brienzo M (2014). The influence of the heterogeneity, physicochemical and structural properties on the recalcitrance and conversion of sugarcane bagasse. Sugarcane: Production, Consumption and Agricultural Management Systems, 1–34

Peng F, Ren JL, Xu F, Bian J, Peng P, Sun RC (2009) Fractional study of alkali-soluble hemicelluloses obtained by graded ethanol precipitation from sugar cane bagasse. J Agric Food Chem 58(3):1768–1776

Yao S, Nie S, Zhu H, Wang S, Song X, Qin C (2017) Extraction of hemicellulose by hot water to reduce adsorbable organic halogen formation in chlorine dioxide bleaching of bagasse pulp. Ind Crop Prod 96:178–185

Busse-Wicher M, Grantham NJ, Lyczakowski JJ, Nikolovski N, Dupree P (2016) Xylan decoration patterns and the plant secondary cell wall molecular architecture. Biochem Soc Trans 44(1):74–78

Chen H (2014). Chemical composition and structure of natural lignocellulose. In Biotechnology of lignocellulose (pp. 25-71). Springer, Dordrecht

Brienzo M, Siqueira AF, Milagres AMF (2009) Search for optimum conditions of sugarcane bagasse hemicellulose extraction. Biochem Eng J 46(2):199–204

Sun S, Cai Y, Liu H (2001) Biomass allocation of Scirpus mariqueter along an elevational gradient in a salt marsh of the Yangtse River estuary. Acta Bot Sin 43(2):178–185

Peng, J., Chen, P., Lou, H., & Zheng, X. (2009). Catalytic upgrading of bio-oil by HZSM-5 in

Fengel D, Wegener G (1984) Wood: chemistry, ultrastructure, reactions, vol 613. Walter Gruyter, pp 1960–1982

Brienzo M, Carvalho W, Milagres AM (2010) Xylooligosaccharides production from alkali-pretreated sugarcane bagasse using xylanases from Thermoascus aurantiacus. Appl Biochem Biotechnol 162(4):1195–1205

Zeng J, Helms GL, Gao X, Chen S (2013) Quantification of wheat straw lignin structure by comprehensive NMR analysis. J Agric Food Chem 61(46):10848–10857

Alonso DM, Bond JQ, Dumesic JA (2010) Catalytic conversion of biomass to biofuels. Green Chem 12(9):1493–1513

York WS, O’Neill MA (2008) Biochemical control of xylan biosynthesis—which end is up? Curr Opin Plant Biol 11(3):258–265

Chundawat, S. P., Beckham, G. T., Himmel, M. E., & Dale, B. E. (2011). Deconstruction of lignocellulosic biomass to fuels and chemicals

Urbanowicz BR, Peña MJ, Ratnaparkhe S, Avci U, Backe J, Steet HF, Darvill AG (2012) 4-O-methylation of glucuronic acid in Arabidopsis glucuronoxylan is catalyzed by a domain of unknown function family 579 protein. Proc Natl Acad Sci 109(35):14253–14258

Moghaddam L, Zhang Z, Wellard RM, Bartley JP, O'Hara IM, Doherty WO (2014) Characterisation of lignins isolated from sugarcane bagasse pretreated with acidified ethylene glycol and ionic liquids. Biomass Bioenergy 70:498–512

Sun Y, Cheng J (2002) Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour Technol 83(1):1–11

Rocha GJM, Gonçalves AR, Nakanishi SC, Nascimento VM, Silva VFN (2015) Pilot scale steam explosion and diluted sulfuric acid pretreatments: comparative study aiming the sugarcane bagasse saccharification. Ind Crop Prod 74:810–816

Ghaffar SH, Fan M (2014) Lignin in straw and its applications as an adhesive. Int J Adhes Adhes 48:92–101

Holladay JE, White JF, Bozell JJ, & Johnson D (2007). Top value-added chemicals from biomass-volume II—results of screening for potential candidates from biorefinery lignin (no. PNNL-16983). Pacific Northwest National Laboratory (PNNL), Richland, WA (US)

Sjostrom E (2013). Wood chemistry: fundamentals and applications. Elsevier

Grisebach H (2016). Lignins I 5. Secondary Plant Products: a Comprehensive Treatise, 7, 457

Fang R, Cheng X, Xu X (2010) Synthesis of lignin-base cationic flocculant and its application in removing anionic azo-dyes from simulated wastewater. Bioresour Technol 101(19):7323–7329

Chung YL, Olsson JV, Li RJ, Frank CW, Waymouth RM, Billington SL, Sattely ES (2013) A renewable lignin–lactide copolymer and application in biobased composites. ACS Sustain Chem Eng 1(10):1231–1238

Hu S, Zhang S, Pan N, Hsieh YL (2014) High energy density supercapacitors from lignin derived submicron activated carbon fibers in aqueous electrolytes. J Power Sources 270:106–112

Labeeuw L, Martone PT, Boucher Y, Case RJ (2015) Ancient origin of the biosynthesis of lignin precursors. Biol Direct 10(1):23

Boitte BC, Rivard M, Majira A, Beauhaire J, Allais F, Martens T et al (2015) Comparative electrochemical study on monolignols and dimers relevant for the comprehension of the lignification process. Phytochem Lett 13:280–285

Eudes A, George A, Mukerjee P, Kim JS, Pollet B, Benke PI et al (2012) Biosynthesis and incorporation of side-chain-truncated lignin monomers to reduce lignin polymerization and enhance saccharification. Plant Biotechnol J 10(5):609–620

Zeng Y, Zhao S, Yang S, Ding SY (2014) Lignin plays a negative role in the biochemical process for producing lignocellulosic biofuels. Curr Opin Biotechnol 27:38–45

Zakzeski J, Bruijnincx PC, Jongerius AL, Weckhuysen BM (2010) The catalytic valorization of lignin for the production of renewable chemicals. Chem Rev 110(6):3552–3599

Verma SR, Dwivedi UN (2014) Lignin genetic engineering for improvement of wood quality: applications in paper and textile industries, fodder and bioenergy production. S Afr J Bot 91:107–125

Simmons BA, Loque D, Ralph J (2010) Advances in modifying lignin for enhanced biofuel production. Curr Opin Plant Biol 13(3):312–319

Oraby HF, Ramadan MF (2015) Impact of suppressing the caffeic acid O-methyltransferase (COMT) gene on lignin, fiber, and seed oil composition in Brassica napus transgenic plants. Eur Food Res Technol 240(5):931–938

Vanholme R, Demedts B, Morreel K, Ralph J, Boerjan W (2010) Lignin biosynthesis and structure. Plant Physiol 153(3):895–905

Carroll A, Somerville C (2009) Cellulosic biofuels. Annu Rev Plant Biol 60:165–182

Vanholme R, Morreel K, Darrah C, Oyarce P, Grabber JH, Ralph J, Boerjan W (2012) Metabolic engineering of novel lignin in biomass crops. New Phytol 196(4):978–1000

Stewart JJ, Akiyama T, Chapple C, Ralph J, Mansfield SD (2009) The effects on lignin structure of overexpression offerulate 5-hydroxylase in hybrid Poplar. Plant Physiology, 150, 621–635

Grabber JH, Hatfield RD, Lu F, Ralph J (2008) Coniferyl ferulate incorporation into lignin enhances the alkaline delignification and enzymatic degradation of cell walls. Biomacromolecules 9(9):2510–2516

Brienzo M, Tyhoda L, Benjamin Y, Görgens J (2015) Relationship between physicochemical properties and enzymatic hydrolysis of sugarcane bagasse varieties for bioethanol production. New Biotechnol 32(2):253–262

Siqueira G, Arantes V, Saddler JN, Ferraz A, Milagres AM (2017) Limitation of cellulose accessibility and unproductive binding of cellulases by pretreated sugarcane bagasse lignin. Biotechnol Biofuels 10(1):176

Nakagame S, Chandra RP, Kadla JF, Saddler JN (2011) Enhancing the enzymatic hydrolysis of lignocellulosic biomass by increasing the carboxylic acid content of the associated lignin. Biotechnol Bioeng 108(3):538–548

Rahikainen J, Mikander S, Marjamaa K, Tamminen T, Lappas A, Viikari L, Kruus K (2011) Inhibition of enzymatic hydrolysis by residual lignins from softwood—study of enzyme binding and inactivation on lignin-rich surface. Biotechnol Bioeng 108(12):2823–2834

Park JW, Takahata Y, Kajiuchi T, Akehata T (1992) Effects of nonionic surfactant on enzymatic hydrolysis of used newspaper. Biotechnol Bioeng 39(1):117–120

Börjesson J, Peterson R, Tjerneld F (2007) Enhanced enzymatic conversion of softwood lignocellulose by poly (ethylene glycol) addition. Enzym Microb Technol 40(4):754–762

Vaidya AA, Newman RH, Campion SH, Suckling ID (2014) Strength of adsorption of polyethylene glycol on pretreated Pinus radiata wood and consequences for enzymatic saccharification. Biomass Bioenergy 70:339–346

Fu C, Mielenz JR, Xiao X, Ge Y, Hamilton CY, Rodriguez M et al (2011) Genetic manipulation of lignin reduces recalcitrance and improves ethanol production from switchgrass. Proc Natl Acad Sci 108(9):3803–3808

Studer MH, DeMartini JD, Davis MF, Sykes RW, Davison B, Keller M, Wyman CE (2011) Lignin content in natural Populus variants affects sugar release. Proc Natl Acad Sci 108(15):6300–6305

Papa G, Varanasi P, Sun L, Cheng G, Stavila V, Holmes B, Singh S (2012) Exploring the effect of different plant lignin content and composition on ionic liquid pretreatment efficiency and enzymatic saccharification of Eucalyptus globulus L. mutants. Bioresour Technol 117:352–359

Li C, Knierim B, Manisseri C, Arora R, Scheller HV, Auer M et al (2010) Comparison of dilute acid and ionic liquid pretreatment of switchgrass: biomass recalcitrance, delignification and enzymatic saccharification. Bioresour Technol 101(13):4900–4906

Yang Q, Pan X (2016) Correlation between lignin physicochemical properties and inhibition to enzymatic hydrolysis of cellulose. Biotechnol Bioeng 113(6):1213–1224

Hendriks ATWM, Zeeman G (2009) Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour Technol 100(1):10–18

Selig MJ, Viamajala S, Decker SR, Tucker MP, Himmel ME, Vinzant TB (2007) Deposition of lignin droplets produced during dilute acid pretreatment of maize stems retards enzymatic hydrolysis of cellulose. Biotechnol Prog 23(6):1333–1339

Hansen MA, Kristensen JB, Felby C, Jørgensen H (2011) Pretreatment and enzymatic hydrolysis of wheat straw (Triticum aestivum L.)–the impact of lignin relocation and plant tissues on enzymatic accessibility. Bioresour Technol 102(3):2804–2811

Wallace J, Brienzo M, García-Aparicio MP, Görgens JF (2016) Lignin enrichment and enzyme deactivation as the root cause of enzymatic hydrolysis slowdown of steam pretreated sugarcane bagasse. New Biotechnol 33(3):361–371

Hu F, Jung S, Ragauskas A (2012) Pseudo-lignin formation and its impact on enzymatic hydrolysis. Bioresour Technol 117:7–12

Sannigrahi P, Kim DH, Jung S, Ragauskas A (2011) Pseudo-lignin and pretreatment chemistry. Energy Environ Sci 4(4):1306–1310

Kumar R, Hu F, Sannigrahi P, Jung S, Ragauskas AJ, Wyman CE (2013) Carbohydrate derived-pseudo-lignin can retard cellulose biological conversion. Biotechnol Bioeng 110(3):737–753

Alvira P, Tomás-Pejó E, Ballesteros MJ, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101(13):4851–4861

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96(6):673–686

Oliveira FM, Pinheiro IO, Souto-Maior AM, Martin C, Gonçalves AR, Rocha GJ (2013) Industrial-scale steam explosion pretreatment of sugarcane straw for enzymatic hydrolysis of cellulose for production of second-generation ethanol and value-added products. Bioresour Technol 130:168–173

Shevchenko SM, Beatson RP, & Saddler JN (1999). The nature of lignin from steam explosion/enzymatic hydrolysis of softwood. In Twentieth Symposium on Biotechnology for Fuels and Chemicals (pp. 867-876). Humana Press, Totowa

Li J, Gellerstedt G, Toven K (2009) Steam explosion lignins; their extraction, structure and potential as feedstock for biodiesel and chemicals. Bioresour Technol 100(9):2556–2561

Rocha GDM, Gonçalves AR, Oliveira BR, Olivares EG, Rossell CEV (2012) Steam explosion pretreatment reproduction and alkaline delignification reactions performed on a pilot scale with sugarcane bagasse for bioethanol production. Ind Crop Prod 35(1):274–279

Nasirpour N, Mousavi SM, Shojaosadati SA (2014) A novel surfactant-assisted ionic liquid pretreatment of sugarcane bagasse for enhanced enzymatic hydrolysis. Bioresour Technol 169:33–37

Thomas LH, Forsyth VT, Šturcová A, Kennedy CJ, May RP, Altaner CM, Jarvis MC (2013) Structure of cellulose microfibrils in primary cell walls from collenchyma. Plant Physiol 161(1):465–476

Kukrety A, Singh RK, Singh P, & Ray SS (2017). Comprehension on the synthesis of carboxymethylcellulose (CMC) utilizing various cellulose rich waste biomass resources. Waste Biomass Valorization, 1–9

French AD (2017) Glucose, not cellobiose, is the repeating unit of cellulose and why that is important. Cellulose 24(11):4605–4609

Bidhendi AJ, Geitmann A (2015) Relating the mechanics of the primary plant cell wall to morphogenesis. J Exp Bot 67(2):449–461

Davison BH, Parks J, Davis MF, & Donohoe BS (2013). Plant cell walls: basics of structure, chemistry, accessibility and the influence on conversion. Aqueous pretreatment of plant biomass for biological and chemical conversion to fuels and chemicals, 23–38

Wang S, Dai G, Yang H, Luo Z (2017) Lignocellulosic biomass pyrolysis mechanism: a state-of-the-art review. Prog Energy Combust Sci 62:33–86

Nakamura A, Watanabe H, Ishida T, Uchihashi T, Wada M, Ando T et al (2014) Trade-off between processivity and hydrolytic velocity of cellobiohydrolases at the surface of crystalline cellulose. J Am Chem Soc 136(12):4584–4592

Yuan X, Duan Y, He L, Singh S, Simmons B, Cheng G (2017) Characterization of white poplar and eucalyptus after ionic liquid pretreatment as a function of biomass loading using X-ray diffraction and small angle neutron scattering. Bioresour Technol 232:113–118

Vena PF, García-Aparicio MP, Brienzo M, Görgens JF, Rypstra T (2013) Effect of alkaline hemicellulose extraction on kraft pulp fibers from Eucalyptus grandis. J Wood Chem Technol 33(3):157–173

Crowe JD, Zarger RA, Hodge DB (2017) Relating nanoscale accessibility within plant cell walls to improved enzyme hydrolysis yields in corn stover subjected to diverse pretreatments. J Agric Food Chem 65(39):8652–8662

Chandra RP, Esteghlalian AR, & Saddler JN (2008). Assessing substrate accessibility to enzymatic hydrolysis by cellulases. Characterization of lignocellulosic materials, 60–80

Arantes V, Saddler JN (2010) Access to cellulose limits the efficiency of enzymatic hydrolysis: the role of amorphogenesis. Biotechnol Biofuels 3(1):4

Cosgrove DJ (2005) Growth of the plant cell wall. Nat Rev Mol Cell Biol 6(11):850–861

Huang R, Su R, Qi W, He Z (2010) Understanding the key factors for enzymatic conversion of pretreated lignocellulose by partial least square analysis. Biotechnol Prog 26(2):384–392

Wang QQ, He Z, Zhu Z, Zhang YH, Ni Y, Luo XL, Zhu JY (2012) Evaluations of cellulose accessibilities of lignocelluloses by solute exclusion and protein adsorption techniques. Biotechnol Bioeng 109(2):381–389

Harmoko C, Sucipto KI, Retnoningtyas ES, Hartono SB (2016) Vinyl functionalized cubic mesoporous silica nanoparticles as supporting material to enhance cellulase enzyme stability. ARPN J Eng Appl Sci 11:2981–2992

Chandra RP, Bura R, Mabee WE, Berlin DA, Pan X, & Saddler JN (2007). Substrate pretreatment: the key to effective enzymatic hydrolysis of lignocellulosics?. In Biofuels (pp. 67-93). Springer Berlin Heidelberg

Luo X, Zhu JY (2011) Effects of drying-induced fiber hornification on enzymatic saccharification of lignocelluloses. Enzym Microb Technol 48(1):92–99

Goufo ED, & Mugisha S (2018). Complex harmonic poles in the evolution of macromolecules depolymerization. J Comput Anal Appl, 1490

Yücel Y, Göycıncık S (2015) Optimization and modelling of process conditions using response surface methodology (RSM) for enzymatic saccharification of spent tea waste (STW). Waste and Biomass Valorization 6(6):1077–1084

Zhao X, Li S, Wu R, & Liu D (2017). Organosolv fractionating pre-treatment of lignocellulosic biomass for efficient enzymatic saccharification: chemistry, kinetics, and substrate structures. Biofuels, Bioproducts and Biorefining

Karimi K, Taherzadeh MJ (2016) A critical review on analysis in pretreatment of lignocelluloses: degree of polymerization, adsorption/desorption, and accessibility. Bioresour Technol 203:348–356

Leu SY, Zhu JY (2013) Substrate-related factors affecting enzymatic saccharification of lignocelluloses: our recent understanding. Bioenergy Res 6(2):405–415

Zhu JY, Pan X, Zalesny RS (2010) Pretreatment of woody biomass for biofuel production: energy efficiency, technologies, and recalcitrance. Appl Microbiol Biotechnol 87(3):847–857

Chen JH, Wang K, Xu F, Sun RC (2015) Effect of hemicellulose removal on the structural and mechanical properties of regenerated fibers from bamboo. Cellulose 22(1):63–72

Ximenes E, Kim Y, Mosier N, Dien B, Ladisch M (2011) Deactivation of cellulases by phenols. Enzym Microb Technol 48(1):54–60

Ek R, Alderborn G, & Nyström C (1994). Particle analysis of microcrystalline cellulose: differentiation between individual particles and their agglomerates. Int J Pharm, 111(1), 43–50

Simons FL (1950) A stain for use in the microscopy of beaten fibers. Tappi 33(7):312–314

Yu X, Minor JL, Atalla RH (1995) Mechanism of action of Simons' stain. TAPPI J 78(6):175–180

Berodier E, Bizzozero J, & Muller AC (2016). Mercury intrusion porosimetry. A Practical Guide to Microstructural Analysis of Cementitious Materials, 419

Orsolini P, Michen B, Huch A, Tingaut P, Caseri WR, Zimmermann T (2015) Characterization of pores in dense nanopapers and nanofibrillated cellulose membranes: a critical assessment of established methods. ACS Appl Mater Interfaces 7(46):25884–25897

Groen JC, Peffer LA, Pérez-Ramı́rez J (2003) Pore size determination in modified micro-and mesoporous materials. Pitfalls and limitations in gas adsorption data analysis. Microporous Mesoporous Mater 60(1–3):1–17

Ciesielski PN, Matthews JF, Tucker MP, Beckham GT, Crowley MF, Himmel ME, Donohoe BS (2013) 3D electron tomography of pretreated biomass informs atomic modeling of cellulose microfibrils. ACS Nano 7(9):8011–8019

Pu Y, Meng X, Yoo CG, Li M, & Ragauskas AJ (2016). Analytical methods for biomass characterization during pretreatment and bioconversion. Valorization of lignocellulosic biomass in a biorefinery: from logistics to environmental and performance impact New York: Nova Science Publishers, 37–78

McIntosh R, Nicastro D, Mastronarde D (2005) New views of cells in 3D: an introduction to electron tomography. Trends Cell Biol 15(1):43–51

Hildebrand T, Rüegsegger P (1997) A new method for the model-independent assessment of thickness in three-dimensional images. J Microsc 185(1):67–75

Reishofer D, & Spirk S (2015). Deuterium and cellulose: a comprehensive review. In Cellulose Chemistry and Properties: Fibers, Nanocelluloses and Advanced Materials (pp. 93-114). Springer, Cham

Lindh EL, Salmén L (2017) Surface accessibility of cellulose fibrils studied by hydrogen–deuterium exchange with water. Cellulose 24(1):21–33

Licari A, Monlau F, Solhy A, Buche P, Barakat A (2016) Comparison of various milling modes combined to the enzymatic hydrolysis of lignocellulosic biomass for bioenergy production: glucose yield and energy efficiency. Energy 102:335–342

da Silva ASA, Teixeira RSS, de Oliveira Moutta R, Ferreira-Leitão VS, de Barros RDRO, Ferrara MA, & da Silva Bon EP (2013). Sugarcane and woody biomass pretreatments for ethanol production. In Sustainable degradation of lignocellulosic biomass-techniques, applications and commercialization. InTech

Lin Z, Huang H, Zhang H, Zhang L, Yan L, Chen J (2010) Ball milling pretreatment of corn stover for enhancing the efficiency of enzymatic hydrolysis. Appl Biochem Biotechnol 162(7):1872–1880

Hideno A, Inoue H, Tsukahara K, Fujimoto S, Minowa T, Inoue S, Sawayama S (2009) Wet disk milling pretreatment without sulfuric acid for enzymatic hydrolysis of rice straw. Bioresour Technol 100(10):2706–2711

Herrera A, Téllez-Luis SJ, Ramırez JA, Vázquez M (2003) Production of xylose from sorghum straw using hydrochloric acid. J Cereal Sci 37(3):267–274

Trajano HL, & Wyman CE (2013). Fundamentals of biomass pretreatment at low pH. Aqueous pretreatment of plant biomass for biological and chemical conversion to fuels and chemicals, 103–128

Alonso DM, Gallo JMR, Mellmer MA, Wettstein SG, Dumesic JA (2013) Direct conversion of cellulose to levulinic acid and gamma-valerolactone using solid acid catalysts. Catal Sci Technol 3(4):927–931

Battista OA (1950) Hydrolysis and crystallization of cellulose. Ind Chemistry 42(3):502–507

Kumar R, Mago G, Balan V, Wyman CE (2009) Physical and chemical characterizations of corn stover and poplar solids resulting from leading pretreatment technologies. Bioresour Technol 100(17):3948–3962

Meng X, Pu Y, Yoo CG, Li M, Bali G, Park DY et al (2017) An in-depth understanding of biomass recalcitrance using natural poplar variants as the feedstock. ChemSusChem 10(1):139–150

Aguilar R, Ramırez JA, Garrote G, Vázquez M (2002) Kinetic study of the acid hydrolysis of sugar cane bagasse. J Food Eng 55(4):309–318

Öhgren K, Galbe M, Zacchi G (2005) Optimization of steam pretreatment of SO2-impregnated corn stover for fuel ethanol production. Appl Biochem Biotechnol 124(1–3):1055–1067

Excoffier G, Toussaint B, Vignon MR (1991) Saccharification of steam-exploded poplar wood. Biotechnol Bioeng 38(11):1308–1317

Du B, Sharma LN, Becker C, Chen SF, Mowery RA, van Walsum GP, & Chambliss CK (2010). Effect of varying feedstock–pretreatment chemistry combinations on the formation and accumulation of potentially inhibitory degradation products in biomass hydrolysates. Biotechnol Bioeng, 107(3), 430–440

Donohoe BS, Decker SR, Tucker MP, Himmel ME, Vinzant TB (2008) Visualizing lignin coalescence and migration through maize cell walls following thermochemical pretreatment. Biotechnol Bioeng 101(5):913–925

Soto ML, Dominguez H, Nunez MJ, Lema JM (1994) Enzymatic saccharification of alkali-treated sunflower hulls. Bioresour Technol 49(1):53–59

Monte JR, Brienzo M, Milagres AMF (2011) Utilization of pineapple stem uice to enhance enzyme-hydrolytic efficiency for sugarcane bagasse after an optimized pre-treatment with alkaline peroxide. Appl Energy 88(1):403–408

Goshadrou A, Lefsrud M (2017) Synergistic surfactant-assisted [EMIM] OAc pretreatment of lignocellulosic waste for enhanced cellulose accessibility to cellulase. Carbohydr Polym 166:104–113

Walker LP, Wilson DB (1991) Enzymatic hydrolysis of cellulose: an overview. Bioresour Technol 36(1):3–14

Lu Y, Yang B, Gregg D, Saddler JN, Mansfield SD (2002) Cellulase adsorption and an evaluation of enzyme recycle during hydrolysis of steam-exploded softwood residues. Appl Biochem Biotechnol 98(1–9):641–654

Mooney CA, Mansfield SD, Touhy MG, Saddler JN (1998) The effect of initial pore volume and lignin content on the enzymatic hydrolysis of softwoods. Bioresour Technol 64(2):113–119

Funding

This study is financially supported by the Brazilian Council for Research and Development (CNPq, process 401900/2016-9; process 401000/2016-9) and the National Institute of Metrology, Quality, and Technology (Prometro grant number 550105/2012-8).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Melati, R.B., Shimizu, F.L., Oliveira, G. et al. Key Factors Affecting the Recalcitrance and Conversion Process of Biomass. Bioenerg. Res. 12, 1–20 (2019). https://doi.org/10.1007/s12155-018-9941-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-018-9941-0