Abstract

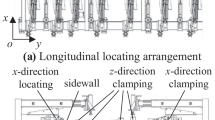

The high-speed train body is welded with aluminum alloy assemblies or parts. Due to the material properties, the welding deformation is much significant. In order to control the welding deformation, this paper takes the sidewall welding of a high-speed train body as the research objective, and carries out the fixture locating modelling and optimization research of the aluminum alloy sidewall. Firstly, a finite element model of the sidewall is established and verified by the comparison between the analysis results and the actual measurement data. Then the residual stress and deformation of the sidewall after welding are analyzed. By selecting the longitudinal parameters of different fixture locating layouts for welding analysis, models describing the relationship between the maximum welding residual stress and maximum welding deformation and the longitudinal fixture locating distance of the sidewall are established. Finally, the fixture locating model of welding deformation is used to optimize the longitudinal fixture locating distance. And the transverse fixture locating distance is also optimized by comparing different locating positions. The result shows that the welding residual stress and the welding deformation have been decreased in the optimal fixture locating layout.

Similar content being viewed by others

References

CAI W, HU S J, YUAN J X. A variational method of robust fixture configuration design for 3-D workpieces [J]. Journal of Manufacturing Science and Engineering, 1997, 119(4): 593–601.

TAN EYT, KUMAR A S, FUHJYH, et al. Modeling, analysis, and verification of optimal fixturing design [J]. IEEE Transactions on Automation Science and Engineering, 2004, 1(2): 121–132.

RAGHU A, MELKOTE S N. Modeling of workpiece location error due to fixture geometric error and fixture-workpiece compliance [J]. Journal of Manufacturing Science and Engineering, 2005, 127(1): 75–83.

IZQUIERDO L E, HU S J, DU H, et al. Robust fixture layout design for a product family assembled in a multistage reconfigurable line [J]. Journal of Manufacturing Science and Engineering, 2009, 131(4): 041008.

LI B, YU H J, YANG X J, et al. Variation analysis and robust fixture design of a flexible fixturing system for sheet metal assembly [J]. Journal of Manufacturing Science and Engineering, 2010, 132(4): 041014.

HEGY, YANGBL, DINGBH, et al. Modeling and compensation technology for the comprehensive errors of fixture system [J]. Chinese Journal of Mechanical Engineering, 2012, 25(2): 385–391.

LU C, ZHAO H W. Fixture layout optimization for de-formable sheet metal workpiece [J]. International Journal of Advanced Manufacturing Technology, 2015, 78: 85–98.

SUNDARARAMAN K A, PADMANABAN K P, SABAREESWARAN M, et al. An integrated finite element method, response surface methodology, and evolutionary techniques for modeling and optimization of machining fixture layout for 3D hollow workpiece geometry [J]. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2017, 231(23): 4344–4359.

MASOUMI A, SHAHI V J. Fixture layout optimization in multi-station sheet metal assembly considering assembly sequence and datum scheme [J]. International Journal of Advanced Manufacturing Technology, 2018, 95: 4629–4643.

QIN G H, WU Z X, ZHANG W H. Analysis and control technique of fixturing deformation mechanism of thin-walled workpiece [J]. Chinese Journal of Mechanical Engineering, 2007, 43(4): 211–216 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (No. 51375277), and the Natural Science Foundation of Shandong Province (No. ZR2016EEM31)

Rights and permissions

About this article

Cite this article

Wang, X., Gao, X. & Yu, K. Fixture Locating Modelling and Optimization Research of Aluminum Alloy Sidewall in a High-Speed Train Body. J. Shanghai Jiaotong Univ. (Sci.) 25, 706–713 (2020). https://doi.org/10.1007/s12204-020-2212-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-020-2212-1