Abstract

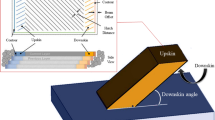

Based on the study of existing typical micro-milling tools and the actual demand for micro-milling tools, the P3 design principle and design flow for ultra-hard micro-milling tool were introduced to give basic guidance for the optimization of micro-milling tools. Then, according to the P3 design flow, the manufacturing process of polycrystalline diamond (PCD) micro-milling tool was proposed, and the PCD micro-milling tool with diameter of 0.5 mm was developed. Finally, the micro-milling test on the slot was carried out to study the milling performance of PCD micro-milling tool.

Similar content being viewed by others

References

Chae J, Park S S, Freiheit T. Investigation of micro-cutting operations[J]. International Journal of Machine Tools and Manufacture, 2006, 46(3–4): 313–332.

Cheng X, Wang Z, Nakamoto K et al. A study on the micro-tooling for micro/nano milling[J]. International Journal of Advanced Manufacturing Technology, 2011, 53(5–8): 523–533.

Aramcharoen A, Mativenga P T. Size effect and tool geometry in micromilling of tool steel[J]. Precision Engineering, 2009, 33(4): 402–407.

Denkena B, Hoffmeister H W, Reichstein M et al. Micro-machining processes for microsystem technology[J]. Microsystem Technologies, 2006, 12(7): 659–664.

Uhlmann E, Schauer K. Dynamic load and strain analysis for the optimization of micro end mills[J]. CIRP Annals — Manufacturing Technology, 2005, 54(1): 75–78.

Aurich J C, Reichenbach I G, Schüler G M. Manufacture and application of ultra-small micro end mills[J]. CIRP Annals — Manufacturing Technology, 2012, 61(1): 83–86.

Cheng X, Nakamoto K, Sugai M et al. Development of ultra-precision machining system with unique wire EDM tool fabrication system for micro/nano-machining[J]. CIRP Annals — Manufacturing Technology, 2008, 57(1): 415–420.

Cheng X, Wang Z G, Nakamoto K et al. Design and development of a micro polycrystalline diamond ball end mill for micro/nano freeform machining of hard and brittle materials[J]. Journal of Micromechanics and Microengineering, 2009, 19(11): 115022.

Fonda P, Katahira K, Kobayashi Y et al. WEDM condition parameter optimization for PCD microtool geometry fabrication process and quality improvement[J]. International Journal of Advanced Manufacturing Technology, 2012, 63(9–12): 1011–1019.

Katahira K, Nakamoto K, Fonda P, et al. A novel technique for reconditioning polycrystalline diamond tool surfaces applied for silicon micromachining[J]. CIRP Annals — Manufacturing Technology, 2011, 60(1): 591–594.

Zhang Z, Peng H, Yan J. Micro-cutting characteristics of EDM fabricated high-precision polycrystalline diamond tools[J]. International Journal of Machine Tools and Manufacture, 2013, 65: 99–106.

Nakamoto K, Katahira K, Ohmori H et al. A study on the quality of micro-machined surfaces on tungsten carbide generated by PCD micro end milling[J]. CIRP Annals — Manufacturing Technology, 2012, 61(1): 567–570.

Torres C D, Heaney P J, Sumant A V et al. Analyzing the performance of diamond-coated micro end mills[J]. International Journal of Machine Tools and Manufacture, 2009, 49(7–8): 599–612.

Fleischer J, Deuchert M, Ruhs C et al. Design and manufacturing of micro milling tools[J]. Microsystem Technologies, 2008, 14(9–11): 1771–1775.

Fang F Z, Wu H, Liu X D et al. Tool geometry study in micromachining[J]. Journal of Micromechanics and Microengineering, 2003, 13(5): 726–731.

Perveen A, San W Y, Rahman M. Fabrication of different geometry cutting tools and their effect on the vertical micro-grinding of BK7 glass[J]. International Journal of Advanced Manufacturing Technology, 2012, 61(1–4): 101–115.

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the National Natural Science Foundation of China (No. 50935003) and Science and Technology Support Project of Jiangsu Province, China (No. BE2012172).

Zhan Zhongbo, born in 1985, male, doctorate student.

Rights and permissions

About this article

Cite this article

Zhan, Z., Li, L., He, N. et al. Design and manufacturing of ultra-hard micro-milling tool. Trans. Tianjin Univ. 20, 415–421 (2014). https://doi.org/10.1007/s12209-014-2257-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12209-014-2257-z