Abstract

It is known that process scaling-up has always been a challenge in biopharmaceutical and food industry. In recent years, newly emerging microscale bioreactors like Ambr15 and Ambr250 have attracted significant attention for that they can provide high throughput and accelerate upstream process development. In this work, we developed the first multiphase Computational Fluid Dynamics (CFD) model for an in-depth characterization of Ambr bioreactor systems. A number of advanced computational methods, including Reynolds stress turbulence model, population balance model, multiple reference frame (MRF), sliding mesh (SM) and user defined functions (UDFs), were integrated for the first time to systematically study the gas-liquid mixing in Ambr250 bioreactor. We provided detailed comparison between MRF and SM method, demonstrated the limitation of MRF for predicting bubble distribution in asymmetric reactors. Characteristics of hydrodynamics, mass transfer, turbulent dissipation and bubble size distribution were predicted from our CFD models and validated by existing experimental data for a variety of operating conditions for both the Ambr15 and Ambr250 bioreactors. The predicted kLa value ranges are 0.18–7.90 h-1 and 2.15–11.52 h-1 for Ambr250 and Ambr15, respectively. This work thus provides a superior framework for the computational modeling of microscale stirred bioreactors.

Similar content being viewed by others

References

Muller, M. M. (2016) Scale–up and scale–down topics facing the industry. Proceedings of the Engineering Conferences International. May.

Xu, P., C. Clark, T. Ryder, C. Sparks, J. Zhou, M. Wang, R. Russell, and C. Scott (2017) Characterization of TAP Ambr 250 disposable bioreactors, as a reliable scale–down model for biologics process development. Biotechnol. Prog. 33: 478–489.

Rafiq, Q. A., A. W. Nienow, and C. J. Hewitt (2017) Process development of human mesenchymal stem cell microcarrier culture using an automated high–throughput microbioreactor.

Yoshida, T., S. Y. Lee, J. Nielsen, and G. Stephanopoulos (2017) Applied Bioengineering: Innovations and Future Directions. John Wiley & Sons.

Pandey, A., C. Larroche, and C. R. Soccol (2017) Current Developments in Biotechnology and Bioengineering: Current Advances in Solid–State Fermentation. Elsevier.

Sherman, M., V. Lam, M. Carpio, N. Hutchinson, and C. Fenge (2016) Continuous cell culture operation at 2,000–L scale. BioProcess Int. 14.

Hsu, W. T., R. P. Aulakh, D. L. Traul, and I. H. Yuk (2012) Advanced microscale bioreactor system: a representative scaledown model for bench–top bioreactors. Cytotechnology 64: 667–678.

Ngibuini, M. (2012) Reducing biomanufacturing bottlenecks: Scale–down reactor automates parameter control and facilitates development. Gen. Eng. Biotechnol. News 33.

Rameez, S., S. S. Mostafa, C. Miller, and A. A. Shukla (2014) High–throughput miniaturized bioreactors for cell culture process development: reproducibility, scalability, and control. Biotechnol. Prog. 30: 718–727.

Kim, B. J., J. Diao, and M. L. Shuler (2012) Mini–scale bioprocessing systems for highly parallel animal cell cultures. Biotechnol. Progress 28: 595–607.

Xia, B. and D.–W. Sun (2002) Applications of computational fluid dynamics (CFD) in the food industry: a review. Comput. Electron. Agric. 34: 5–24.

Kremer, D. M. and B. C. Hancock (2006) Process simulation in the pharmaceutical industry: a review of some basic physical models. J. Pharm. Sci. 95: 517–529.

Sarkar, J., L. K. Shekhawat, V. Loomba, and A. S. Rathore (2016) CFD of mixing of multi–phase flow in a bioreactor using population balance model. Biotechnol. Progress 32: 613–628.

Zhang, H., W. Williams–Dalson, E. Keshavarz–Moore, and P. A. Shamlou (2005) Computational–fluid–dynamics (CFD) analysis of mixing and gas–liquid mass transfer in shake flasks. Biotechnol. Appl. Biochem. 41: 1–8.

Utomo, T., Z. Jin, M. Rahman, H. Jeong, and H. Chung (2008) Investigation on hydrodynamics and mass transfer characteristics of a gas–liquid ejector using three–dimensional CFD modeling. J. Mech. Sci. Technol. 22: 1821–1829.

Gimbun, J., C. D. Rielly, and Z. K. Nagy (2009) Modelling of mass transfer in gas–liquid stirred tanks agitated by Rushton turbine and CD–6 impeller: a scale–up study. Chem. Eng. Res. Design 87: 437–451.

Gelves, R., A. Dietrich, and R. Takors (2014) Modeling of gasliquid mass transfer in a stirred tank bioreactor agitated by a Rushton turbine or a new pitched blade impeller. Bioprocess Biosyst. Eng. 37: 365–375.

Higbie, R. (1935) The rate of absorption of a pure gas into still liquid during short periods of exposure. Trans. AIChE 31: 365–389.

Kapic, A. and T. J. Heindel (2006) Correlating gas–liquid mass transfer in a stirred–tank reactor. Chem. Eng. Res. Design 84: 239–245.

Dhanasekharan, K. M., J. Sanyal, A. Jain, and A. Haidari (2005) A generalized approach to model oxygen transfer in bioreactors using population balances and computational fluid dynamics. Chem. Eng. Sci. 60: 213–218.

Khopkar, A. R., G. R. Kasat, A. B. Pandit, and V. V. Ranade (2006) CFD simulation of mixing in tall gas–liquid stirred vessel: Role of local flow patterns. Chem. Eng. Sci. 61: 2921–2929.

Xia, J.–Y., Y.–H. Wang, S.–L. Zhang, N. Chen, P. Yin, Y.–P. Zhuang, and J. Chu (2009) Fluid dynamics investigation of variant impeller combinations by simulation and fermentation experiment. Biochem. Eng. J. 43: 252–260.

Scargiali, F., A. D’Orazio, F. Grisafi, and A. Brucato (2007) Modelling and simulation of gas–liquid hydrodynamics in mechanically stirred tanks. Chem. Eng. Res. Design 85: 637–646.

Cheung, S. C. P., G. H. Yeoh, and J. Y. Tu (2007) On the numerical study of isothermal vertical bubbly flow using two population balance approaches. Chem. Eng. Sci. 62: 4659–4674.

Ahmed, S. U., P. Ranganathan, A. Pandey, and S. Sivaraman (2010) Computational fluid dynamics modeling of gas dispersion in multi impeller bioreactor. J. Biosci. Bioeng. 109: 588–597.

Sajjadi, B., A. A. A. Raman, S. Ibrahim, and R. S. S. R. E. Shah (2012) Review on gas–liquid mixing analysis in multiscale stirred vessel using CFD. Rev. Chem. Eng. 28: 171–189.

Nienow, A. W., C. D. Rielly, K. Brosnan, N. Bargh, K. Lee, K. Coopman, and C. J. Hewitt (2013) The physical characterisation of a microscale parallel bioreactor platform with an industrial CHO cell line expressing an IgG4. Biochem. Eng. J. 76: 25–36.

Rutherford, K., K. C. Lee, S. M. S. Mahmoudi, and M. Yianneskis (1996) Hydrodynamic characteristics of dual Rushton impeller stirred vessels. AIChE J. 42: 332–346.

Bareither, R., N. Bargh, R. Oakeshott, K. Watts, and D. Pollard (2013) Automated disposable small scale reactor for high throughput bioprocess development: A proof of concept study. Biotechnol. Bioeng. 110: 3126–3138.

De Wilde, D., T. Dreher, C. Zahnow, U. Husemann, G. Greller, T. Adams, and C. Fenge (2014) Superior scalability of single–use bioreactors. BioProcess Int. 12: 14–19.

Azargoshasb, H., S. M. Mousavi, O. Jamialahmadi, S. A. Shojaosadati, and S. B. Mousavi (2016) Experiments and a threephase computational fluid dynamics (CFD) simulation coupled with population balance equations of a stirred tank bioreactor for high cell density cultivation. Can. J. Chem. Eng. 94: 20–32.

Elqotbi, M., S. D. Vlaev, L. Montastruc, and I. Nikov (2013) CFD modelling of two–phase stirred bioreaction systems by segregated solution of the Euler–Euler model. Comput. Chem. Eng. 48: 113–120.

Kerdouss, F., A. Bannari, and P. Proulx (2006) CFD modeling of gas dispersion and bubble size in a double turbine stirred tank. Chem. Eng. Sci. 61: 3313–3322.

Jaworski, Z., K. N. Dyster, V. P. Mishra, A. W. Nienow, and M. L. Wyszynski (1998) A study of an up–and a down–pumping wide–blade hydrofoil impeller: Part II. CFD analysis. Can. J. Chem. Eng. 76: 866–876.

ANSYS, I., ANSYS Fluent Theory Guide Release 17.0.

Schiller, V. L. (1933) A drag coefficient correlation. Z. Vereines Ingenieure 77: 318–320.

Murthy, B. N. and J. B. Joshi (2008) Assessment of standard k–e, RSM and LES turbulence models in a baffled stirred vessel agitated by various impeller designs. Chem. Eng. Sci. 63: 5468–5495.

Delafosse, A., A. Line, J. Morchain, and P. Guiraud (2008) LES and URANS simulations of hydrodynamics in mixing tank: comparison to PIV experiments. Chem. Eng. Res. Design 86: 1322–1330.

Paul, E. L., V. A. Atiemo–Obeng, and S. M. Kresta (2004) Handbook of Industrial Mixing: Science and Practice. John Wiley & Sons.

ANSYS, I., ANSYS Fluent Population Balance Module Manual Release 17.0.

Luo, H. and H. F. Svendsen (1996) Theoretical model for drop and bubble breakup in turbulent dispersions. AIChE J. 42: 1225–1233.

Ranganathan, P. and S. Sivaraman (2011) Investigations on hydrodynamics and mass transfer in gas–liquid stirred reactor using computational fluid dynamics. Chem. Eng. Sci. 66: 3108–3124.

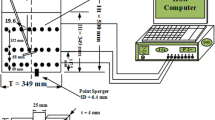

Miyahara, T., Y. Matsuba, and T. Takahashi (1983) The size of bubbles generated from perforated plates. Int. Chem. Eng. 23: 517–523.

Kane, J. (2012) Measuring kLa for better bioreactor performance. BioProcess Int. 10.

Kelly, W. J. (2008) Using computational fluid dynamics to characterize and improve bioreactor performance. Biotechnol. Appl. Biochem. 49: 225–238.

Van’t Riet, K. (1979) Review of measuring methods and results in nonviscous gas–liquid mass transfer in stirred vessels. Ind. Eng. Chem. Process Des. Dev. 18: 357–364.

Nienow, A. W. and M. D. Lilly (1979) Power drawn by multiple impellers in sparged agitated vessels. Biotechnol. Bioeng. 21: 2341–2345.

Nienow, A. W. (1998) Hydrodynamics of stirred bioreactors. Appl. Mech. Rev. 51: 3–32.

Hall, S. (2017) Rules of Thumb for Chemical Engineers. 6th ed. Butterworth–Heinemann.

Khopkar, A. R. and P. A. Tanguy (2008) CFD simulation of gas–liquid flows in stirred vessel equipped with dual rushton turbines: influence of parallel, merging and diverging flow configurations. Chem. Eng. Sci. 63: 3810–3820.

Zhou, G. and S. M. Kresta (1996) Impact of tank geometry on the maximum turbulence energy dissipation rate for impellers. AIChE J. 42: 2476–2490.

Hortsch, R. and D. Weuster–Botz (2010) Power consumption and maximum energy dissipation in a milliliter–scale bioreactor. Biotechnol. Prog. 26: 595–599.

Wernersson, E. S. and C. Trägårdh (1999) Scale–up of Rushton turbine–agitated tanks. Chem. Eng. Sci. 54: 4245–4256.

Wang, T., J. Wang, and Y. Jin (2006) A CFD–PBM coupled model for gas–liquid flows. AIChE J. 52: 125–140.

Calderbank, P. H. (1958) Physical rate processes in industrial fermentation, Part I: The interfacial area in gas–liquid contacting with mechanical agitation. Trans. Instn. Chem. Engrs. 36: 443–463.

Paceka, A. W., C. C. Mana, and A. W. Nienow (1998) On the Sauter mean diameter and size distributions in turbulent liquid/ liquid dispersions in a stirred vessel. Chem. Eng. Sci. 53: 2005–2011.

Olmos, E., C. Gentric, C. Vial, G. Wild, and N. Midoux (2001) Numerical simulation of multiphase flow in bubble column reactors. Influence of bubble coalescence and break–up. Chem. Eng. Sci. 56: 6359–6365.

Camarasa, E., C. Vial, S. Poncin, G. Wild, N. Midoux, and J. Bouillard (1999) Influence of coalescence behaviour of the liquid and of gas sparging on hydrodynamics and bubble characteristics in a bubble column. Chem. Eng. Processing: Process Intensification 38: 329–344.

Laakkonen, M., P. Moilanen, V. Alopaeus, and J. Aittamaa (2007) Modelling local gas–liquid mass transfer in agitated vessels. Chem. Eng. Res. Design 85: 665–675.

Chapple, D., S. M. Kresta, A. Wall, and A. Afacan (2002) The effect of impeller and tank geometry on power number for a pitched blade turbine. Chem. Eng. Res. Design 80: 364–372.

Rutherford, K., S. M. Mahmoudi, K. C. Lee, and M. Yianneskis (1996) The influence of Rushton impeller blade and disk thickness on the mixing characteristics of stirred vessels. Chem. Eng. Res. Design 74: 369–378.

Rushton, J. H. (1950) Power characteristics of mixing impellers Part 1. Chem. Eng. Prog. 46: 395–404.

Bates, R. L., P. L. Fondy, and R. R. Corpstein (1963) Examination of some geometric parameters of impeller power. Ind. Eng. Chem. Process Design Dev. 2: 310–314.

Gill, N., M. Appleton, F. Baganz, and G. Lye (2008) Quantification of power consumption and oxygen transfer characteristics of a stirred miniature bioreactor for predictive fermentation scale–up. Biotechnol. Bioeng. 100: 1144–1155.

Betts, J. I., and F. Baganz (2006) Miniature bioreactors: current practices and future opportunities. Microb. Cell Fact. 5: 21.

Garcia–Ochoa, F. and E. Gomez (2009) Bioreactor scale–up and oxygen transfer rate in microbial processes: an overview. Biotechnol. Adv. 27: 153–176.

Kaiser, S. C., C. Löffelholz, S. r. Werner, and D. Eibl (2011) CFD for characterizing standard and single–use stirred cell culture bioreactors. pp. 97–122 In: P. I. Minin (ed.). Computational Fluid Dynamics Technologies and Applications. InTech, City.

Nienow, A. W. (2006) Reactor engineering in large scale animal cell culture. Cytotechnology 50: 9–33.

MixIT, MRF versus Sliding Mesh. http://mixit.tridiagonal.com/multiple–reference–frame–mrf–versus–sliding–mesh.

Montante, G., K. C. Lee, A. Brucato, and M. Yianneskis (2001) Numerical simulations of the dependency of flow pattern on impeller clearance in stirred vessels. Chem. Eng. Sci. 56: 3751–3770.

Jakirlic, S. and R. Maduta (2015) Extending the bounds of ‘steady’ RANS closures: Toward an instability–sensitive Reynolds stress model. Int. J. Heat Fluid Flow 51: 175–194.

Vikhansky, A. and A. Splawski (2015) Adaptive multiply size group method for CFD–population balance modelling of polydisperse flows. Can. J. Chem. Eng. 93: 1327–1334.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Li, X., Scott, K., Kelly, W.J. et al. Development of a Computational Fluid Dynamics Model for Scaling-up Ambr Bioreactors. Biotechnol Bioproc E 23, 710–725 (2018). https://doi.org/10.1007/s12257-018-0063-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12257-018-0063-5