Abstract

The walnut varieties in China are rich, the planting area in the country is wide, and the yield ranks at the forefront of the world. Walnut kernel is the most important application part of the walnut fruit. An in-depth study found that the by-products of walnut, such as green husk and walnut shell, also have great application potential and are cheap raw materials for the extraction of important medical ingredients and the production of industrial products. However, the by-products are often burned or discarded as waste during processing, which not only wastes resources but also causes environmental pollution. To realize the high value-added application of the walnut fruit, a deep processing of each part of the walnut should be considered. Preliminary processing is the key link before walnuts enter the field of intensive processing and consumption. The advanced level of the required technological equipment can help to determine the quality of the walnut products. The preliminary processing of walnuts in China is mainly divided into six steps: green husk removal, walnut drying, walnut size classification, walnut shell-breaking, walnut shell–kernel separation, and walnut kernel skin removal. This paper starts with a presentation of the importance of each link and the existing bottleneck. Then, the paper systematically discusses the analysis of the current situation and the development of devices required for each link. The working mechanism of each link type and its influence on the design of a corresponding device are summarized. On the basis of the corresponding working mechanism, this study classifies and summarizes the characteristics of the core mechanism of the devices for each preliminary process link; then, it evaluates and analyzes the existing typical mechanical devices according to their types. Finally, the influence rule of the various devices for each link in the preliminary processing is analyzed as a means of ensuring high-quality walnuts.

Similar content being viewed by others

References

Cao SY, Li H (2017) Chinese walnut local species Atlas. China Forestry Press, Beijing

Pei D, Lu XZ (2011) Walnut germplasm resources in China. China Forestry Press, Beijing

Ge Z (2016) Analysis on the international competitivenessand trade potentialof chinese walnuts. Nanjing Agri Univ

Jahanban-Esfahlan A, Ostadrahimi A, Tabibiazar M, Amarowicz R (2019) A comprehensive review on the chemical constituents and functional uses of walnut (Juglans spp.) husk. Int J Mol Sciences 20(16)

Rabadan A, Pardo JE, Gomez R, Alvarez-Orti M (2018) Evaluation of physical parameters of walnut and walnut products obtained by cold pressing. LWT-Food Sci Technol 91:308–314

Pycia K, Kapusta I, Jaworska G, Jankowska A (2019) Antioxidant properties, profile of polyphenolic compounds and tocopherol content in various walnut (Juglans regia L.) varieties. Eur Food Res Technol 245(3):607–616

Zhao Y, Fan C, Zhang A, Zhang Y, Wang FJ, Weng Q, Xu MY (2020) Walnut polyphenol extract protects against malathion- and chlorpyrifos-induced immunotoxicity by modulating TLRx-NOX-ROS. Nutrients 12(3)

Martinez ML, Labuckas DO, Lamarque AL, Maestri DM (2010) Walnut (Juglans regia L.): Genetic resources, chemistry, by-products. J Agric Food Sci 90(12):1959–1967

Gupta S, Gupta GK, Mondal MK (2019) Slow pyrolysis of chemically treated walnut shell for valuable products: Effect of process parameters and in-depth product analysis. Energy 181:665–676

Banerjee M, Basu RK, Das SK (2018) Cr(VI) adsorption by a green adsorbent walnut shell: Adsorption studies, regeneration studies, scale-up design and economic feasibility. Process Saf Environ Prot 116:693–702

Zhu YX, Song H, Zhang X, Chen CY, Zhao SL, Ge F, Liu DQ (2017) Recovery of flavonoids from walnuts de-pellicle wastewater with macroporous resins and evaluation of antioxidant activities in vitro. J Food Process Eng 40(1)

Yang ZQ, Yan SK, Cui KB, Wang QH, Sun LN, Abulizi (2019) A survey of green walnut processing and complete sets of equipment between the United States and China. Food Mach 35(11):228–232

Soto-Maldonado C, Vergara-Castro M, Jara-Quezada J, Caballero-Valdes E, Muller-Pavez A, Zuniga-Hansen ME, Altamirano C (2019) Polyphenolic extracts of walnut (Juglans regia) green husk containing juglone inhibit the growth of HL-60 cells and induce apoptosis. Electron J Biotechnol 39:1–7

Zhou YY, Song HJ, Guo S, Wang Y, Gao HR, Zhang XJ, Sun YP, Liu Y, Yang BY, Kuang HX (2019) A new triterpene from the green walnut husks of Juglans mandshurica Maxim. J Nat Med 73(4):800–804

Tsasi G, Samara P, Tsitsilonis O, Jurgenliemk G, Skaltsa H (2016) Isolation, identification and cytotoxic activity of triterpenes and flavonoids from green walnut (Juglans regia L.) pericarps. Rec Nat Prod 10(1): 83–92

Wang AD, Xie XY, Zeng WM, Liu JY, Xu YN (2019) New α-ditetralony glucoside from the green walnut husk of Juglans mandshurica. Nat Prod Res 1–7

Wang H, Hu PF, Yang J, Gong GM, Guo L, Chen XD (2015) Renewable-juglone-based high-performance sodium-ion batteries. Adv Mater 27(14):2348–2354

Hu WY, Du WC, Bai SM, Lv ST, Chen G (2018) Phenoloxidase, an effective bioactivity target for botanical insecticide screening from green walnut husks. Nat Prod Res 32(23):2848–2851

He NW, Zhai XC, Zhang XB, Zhang XW, Wang XJ (2020) Extraction, purification and characterization of water-soluble polysaccharides from green walnut husk with anti-oxidant and antiproliferative capacities. Process Biochem 88:170–179

Beiki T, Najafpour GD, Hosseini M (2018) Evaluation of antimicrobial and dyeing properties of walnut (Juglans regia L.) green husk extract for cosmetics. Color Technol 134(1): 71–81

Qu WW, Xia YH, Peng JH, Zhang LB, Zhang ZY, Yang KB (2009) Pyrolysis characteristics and kinetic analysis of walnut shell. Transactions of the CSAE 2:194–198

Yuan T, He WJ, Yin GJ, Xu S (2020) Comparison of bio-chars formation derived from fast and slow pyrolysis of walnut shell. Fuel 261

Al Mesfer MK (2020) Synthesis and characterization of high-performance activated carbon from walnut shell biomass for CO2 capture. Environ Sci Pollut R 27(13):15020–15028

Martinez ML, Torres MM, Guzman CA, Maestri DM (2007) Preparation and characteristics of activated carbon from olive stones and walnut shells. Ind Crop Prod 23(1):23–28

Tang GX, Zhang LQ, Zhu XF, Zhu XF (2020) The preparation of activated carbon from walnut shell bio-oil distillation residues. Carbon 158:930–931

Xu XY, Zhang XJ, Zhao Y, Hu YQ (2018) An efficient hybrid supercapacitor based on battery-type MnS/reduced graphene oxide and capacitor-type biomass derived activated carbon. J Mater Sci-Mater El 29(10):8410–8420

Laguna-Camacho JR, Hernandez-Romero I, Escalante-Martinez JE, Marquez-Vera CA, Galvan-Lopez JL, Mendez-Mendez JV, Arzate-Vazquez I, Andraca-Adame JA (2015) Erosion wear of AISI 420 stainless steel caused by walnut shell particles. T Indian I Metals 68(4):633–647

Zhou SW, Wei YG, Li B, Wang H (2019) Cleaner recycling of iron from waste copper slag by using walnut shell char as green reductant. J Clean Prod 217:423–431

Orue A, Eceiza A, Arbelaiz A (2020) The use of alkali treated walnut shells as filler in plasticized poly(lactic acid) matrix composites. Ind Crop Prod 145

Barczewski M, Salasinska K, Szulc J (2019) Application of sunflower husk, hazelnut shell and walnut shell as waste agricultural fillers for epoxy-based composites: A study into mechanical behavior related to structural and rheological properties. Polym Testing 75:1–11

Wang X, Zhao MM, Su GW, Cai MS, Sun-Waterhouse D, Zhou CM, Lin LZ (2016) Antihyperuricemic activities of an ethanolic and aqueous extract of Walnut (Juglans regia L.) shell and a new aldehyde xanthine oxidase inhibitor. Int Food Res J 51(2): 453–460

Li J, Zhao ZH, Li DM, Tang XH, Feng H, Qi W, Wang Q (2017) Multifunctional walnut shell layer used for oil/water mixtures separation and dyes adsorption. Appl Surf Sci 419:869–874

Gao P, Liu RJ, Jin QZ, Wang XG (2019) Comparison of solvents for extraction of walnut oils: Lipid yield, lipid compositions, minor-component content, and antioxidant capacity. LWT-Food Sci Technol 110:346–352

Geng QN, Chen J, Guo R, Zhang LY, Li Q, Yu XZ (2020) Salt-assisted aqueous extraction combined with Span 20 allow the obtaining of a high-quality and yield walnut oil. LWT-Food Sci Technol 121

Rusu ME, Georgiu C, Pop A, Mocan A, Kiss B, Vostinaru O, Fizesan I, Stefan MG, Gheldiu AM, Mates L, Moldovan R, Muntean DM, Loghin F, Vlase L, Popa DS (2020) Antioxidant effects of walnut (Juglans Regia L.) kernel and walnut septum extract in a d-galactose-induced aging model and in naturally aged rats. Antioxidants 9(5)

Liao JQ, Nai YF, Feng L, Chen YM, Li M, Xu HD (2020) Walnut oil prevents scopolamine-induced memory dysfunction in a mouse model. Molecules 25(7)

Bartoszek A, Makaro A, Bartoszek A, Kordek R, Fichna J, Salaga M (2020) Walnut oil alleviates intestinal inflammation and restores intestinal barrier function in mice. Nutrients 12(5)

Li JN, Xi XL, Xiong XW, Yang JH, Zhang YS (2018) Nutritional function and functional components of walnut. Food Nutr China 24(5):60–64

Zhao XY, Liu HK, Zhang XW, Zhu HT (2019) Comparison of structures of walnut protein fractions obtained through reverse micelles and alkaline extraction with isoelectric precipitation. Int J Biol Macromol 125:1214–1220

Yang YT, Pan SY, Jin XX, Gao F, Tian YZ, Ding XL (2017) Amino acid composition and nutritional evaluation of different varieties of walnut. Food Sci 38(13):207–212

Chen HJ, Li XF, Gao HY, Fang XJ (2013) The analysis of chemical composition and antioxidant activities of phenolic compounds from carya (carya cathayensis) kernel. J Nucl Agri Sci 1:61–67

Blornhoff R, Carlsen MH, Andersen LF, Jacobs DR (2008) Health benefits of nuts: Potential role of antioxidants. Br J Nutr 99(2):448–448

Shi DD, Chen CY, Zhao SL, Ge F, Liu DQ, Song H (2014) Walnut polyphenols inhibit pancreatic lipase activity in vitro and have hypolipidemic effect on high-fat diet-induced obese mice. J Food Nutr Res 2(10):757–763

Stagos D (2020) Antioxidant activity of polyphenolic plant extracts Antioxidants 9(1)

Hejniak J, Baranowska I, Stencel S, Bajkacz S (2019) Separation and Determination of Selected Polyphenols from Medicinal Plants. J Chromatogr Sci 57(1):17–26

Maji TK, Bagchi D, Pan N, Sayqal A, Morad M, Ahmed SA, Karmakar D, Pal SK (2020) A combined spectroscopic and ab initio study of the transmetalation of a polyphenol as a potential purification strategy for food additives. Rsc Advances 10(10):5636–5647

Zhu YX (2016) Effect of polyphenols from walnut ontyrosinase aactivity and melanogenesis andpreparation of cosmetic. Kunming Univ Sci Technol

Xu LQ, Neoh KG, Kang ET (2018) Natural polyphenols as versatile platforms for material engineering and surface functionalization. Prog Polym Sci 87:165–196

Behboodi-Sadabad F, Zhang HJ, Trouillet V, Welle A, Plumere N, Levkin PA (2017) UV-triggered polymerization, deposition, and patterning of plant phenolic compounds. Adv Funct Mater 27(22)

Zhu ZJ, Yang ZQ, Li Y, Sun LN, Yang LL, Li ZX, Liu K (2017) Peeling mechanical properties analysis of green walnut. J Agri Mech Res 19(6):83–89

Mo KL, Jiang CR, Xu M, Yang XB, Fu ZR (2016) Effect of different walnut green husk removal technology on nut quality. Journal of Sichuan Forestry Science and Technology 2:91–93

Chen C, Venkitasamy C, Zhang WP, Khir R, Upadhyaya S, Pan ZL (2020) Effective moisture diffusivity and drying simulation of walnuts under hot air. Int J Heat Mass Tran 150

Jiang M (2013) Drying characteristics and mass transfer simulation of sigillate walnut (Juglans sigillata dode) during convection drying. Kunming Univ Sci Technol

Xiao DC (2007) Moisture diffusivity in food and biological materials. Drying Technol 25(7–8):1203–1213

Wang B, Tian X, Li ZX, Wang QH, Shen XH, Ma WQ (2017) Current situation and analysis of walnut drying technologies. J Chinese Agri Mech 38(5):118–123

Zhang JG, Li MY, Cheng JH, Wang J, Ding ZE, Yuan XL, Zhou SM, Liu XM (2019) Effects of moisture, temperature, and salt content on the dielectric properties of pecan kernels during microwave and radio frequency drying processes. Foods 8(9)

Hu BK, Xu L, Chen J, He GT (2013) Effect of drying temperature on quality of walnut. Sci Technol Food Ind, (4): 285–288, 292

Geng YY, Hou N, He JL, Wang JH, Liang M, Hu BK, Hu YW (2018) Effect of the gradient temperature drying on sensory quality in fresh walnut. Food Sci Technol 43(2):64–69

Zhang H, Shen LY, Lan HP, Li Y, Liu Y, Tang YR, Li W (2018) Mechanical properties and finite element analysis of walnut under different cracking parts. Int J Agr Biol Eng 11(6):81–88

Fu YJ, Yang S, Wang FJ, Yuan TQ (2018) Structural characterization of lignin from walnut shell. J For Eng 3(3):88–94

Wu ZY (1995a) Research on principle and mechanics of cracking and extracting kernel of soft-walnut. Transactions of the CSAE 4:164–169

Wu ZY (1995b) Mechanical analysis of cracking walnut. J Nanjing Agri Univ 3:116–123

Gharibzahedi SMT, Mousavi SM, Hamedi M, Khodaiyan F, Dadashpour A (2012) Mechanical behavior of persian walnut and its kernel under compression loading: An experimental and computational study. J Food Process Preserv 36(5):423–430

Koyuncu MA, Ekinci K, Savran E (2003) Cracking characteristics of walnut. Biosys Eng 87(3):305–311

Faroogh S, Mohammadali HD (2008) Mechanical behavior of walnut under cracking conditions. Int J Appl Sci 8(5):886–890

Gao J, Zheng JL, Yan R, Liu MF, Lu P (2014) Study on influencing factors of walnut’ s shelled force. J Agri Mech Res 36(9):186–189

Shahbazi F (2014) Effects of moisture content and impact energy on the cracking characteristics of walnuts. Int J Food Eng 10(1):149–156

Zhang H, Ma Y, Li Y, Zhang RL, Zhang XJ, Zhang R (2014) Rupture energy prediction model for walnut shell breaking based on genetic BP neural network. Transactions of the CSAE 30(18):78–84

Krishnan P, Berlage AG (1984) Separation of shells from walnut meats using magnetic methods. T ASAE 27(6):1990–1992

Zhang YB, Liu Y, Liu MZ, Ji XP, Wang L, Li CH (2014) Design and experimental study of a walnut decorticating and kernel taking out machine. J Agri Mech Res (4): 132–136 146

Ma QC, Lu AG, Gao LX, Wang ZG, Tan ZH, Li XQ (2015) Aerodynamic characteristics of lotus seed mixtures and test on pneumatic separating device for lotus seed kernel and contaminants. Transactions of the CSAE 31(6):297–303

Tuluhong D, Yang HM, Ayimunisha B (2018) Experimental research on shell and kernel separator of almonds. J Agri Mech Res 40(4):167–171

Zhu ZJ, Li ZX, Yang LL, Liu K, Abulizi LJ (2014) Research progress on the separation technology of walnut shell-kernel. Food Industries 35(2):216–219

Hou HM, Cui QL, Guo YM, Zhang YQ, Sun D, Lai ST, Liu JL (2018) Design and test of air-sweeping suspension velocity testing device for cleaning threshed materials of grain and oil crops. Transactions of the CSAE 34(16):43–49

Khir R, Pan Z, Atungulu GG, Thompson JF (2014) Characterization of physical and aerodynamic properties of walnuts. T Asabe 57(1):53–61

Cao CM, Luo K, Peng ML, Wu ZM, Liu GZ, Li Z (2019) Experiment on winnowing mechanism and winnowing performance of hickory material. Transactions of the CSAE 50(9):105–112

Ma H (2011) Study on design and experiment of separator machine for walnut shell and kernel. Xinjiang Agri Univ

Zhou Y (2013) Analysis of walnut pellicle polyphenols and antioxidant activities. Chinese Academy For Sci

Shirmohammadli Y, Efhamisisi D, Pizzi A (2018) Tannins as a sustainable raw material for green chemistry: A review. Ind Crop Prod 126:316–332

do Prado ACP, da Silva HS, da Silveira SM, Barreto PLM, Vieira CRW, Maraschin M, Ferreira SRS, Block JM (2014) Effect of the extraction process on the phenolic compounds profile and the antioxidant and antimicrobial activity of extracts of pecan nut shell. Ind Crop Prod 52:552–561

Sanchez-Gonzalez C, Ciudad CJ, Noe V, Izquierdo-Pulido M (2017) Health benefits of walnut polyphenols: An exploration beyond their lipid profile. Crit Rev Food Sci Nutr 57(16):3373–3383

Zhang ZH, Pei D (2018) Walnut Science. China Agricultural Press, Beijing

Zhang XD, Yang JX, Wang D, Wang ML, Xin L (2018) Optimization of extraction technique and physicochemical property of pectin from persimmon. Sci Technol Food Ind 39(8):147–153

Liu DQ, Lu JD, Wang YN, Tian ZH, Wang P, Zou C (2014) Green walnut peeling machine. CN2014105449515

Kadeer K, Baketi H, Liu XN, Zhu HT, Zhang JS, Wei YX (2010) Green walnut peeling and cleaning machine. CN2010205072592

Zhang ZG, Ma JL, Zhang YC (2015) Peeling-cleaning all-in-one machine for green walnuts. CN2014104736298

Liang QA, Yang J, Shi HF, Liu XL (2003) Walnut soft shell peeling and cleaning machine. CN022064079

Li ZX, Yang LL, Yang ZQ, Cui KB, Zhu ZJ, Liu K, Liu J, Shen XH, Maihemujiang (2011) Continuous type green walnut shelling machine. CN2011101815909

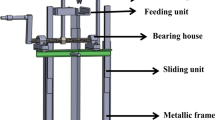

Yang ZQ, Li ZX, Yang LL, Liu K, Zhu ZJ, Liu J (2013) Design and experiment of walnut hulling devices. J Chinese Agri Mech 5:190–194

Shi ZC (2019) Design and numerical simulation of a small and efficient walnut peeler. Xinjiang Univ

Wu DZ (2016) Research on peeling method of walnut peel and machine design. Shaanxi Univ Sci Technol

Pahaerding, Yang LL, Yang ZQ, Zhu ZJ, Cui KB, Liu K, Liu J (2010) Machine for peeling and cleaning green walnuts. CN2010205396248

Shi X (2010) Study on design and experiment of green walnut peeling and cleaning machine. Xinjiang Agri Univ

Jiang LX (2013) Study on the design and experiment of walnut-peeling machine. Xinjiang Agri Univ

Wang YN, Lu JD, Wang W, Tian ZH, He GM, Cao JL (2014) A design and experimental research on a green walnut peeling machine. Packag Food Mach 1:32–34

Wei F, Chen QM, Fu MR, Ma ZC (2018) Effect of peeling methods on chemical compounds and functional activities of green walnut husk. Food Sci Technol 43(12):259–265

Liang QA, Yang J, Sun Y, Liu C, Liu XL, Shi HF (2004) Analysis of influence of factors on hulling rate and damage rate during hulling walnuts. Transactions of the CSAE 20(5):225–227

Liang QA, Yang J, Sun Y, Liu C, Liu XL, Shi HF (2004) Analysis of influence of factors on hulling rate and damage rate during hulling walnuts. Transactions of the CSAE 20(5):225–227

Cui KB, Li ZX, Yang LL, Abulizi YZQ, Liu K, Yan SK, Liu J, Zhu ZJ, Ma WQ (2014) Situation analysis of walnut processing industry. Cereals oils proc 8:56–60

Hassan-Beygi SR, Aghbashlo M, Kianmehr MH, Massah J (2009) Drying characteristics of walnut (Juglans regia L.) during convection drying. Int Agrophys 23(2): 129–135

Chen C, Venkitasamy C, Zhang WP, Deng LZ, Meng XY, Pan ZL (2020) Effect of step-down temperature drying on energy consumption and product quality of walnuts. J Food Eng 285

Chen C, Zhang WP, Venkitasamy C, Khir R, McHugh T, Pan ZL (2020) Walnut structure and its influence on the hydration and drying characteristics. Drying Technol 38(8):975–986

Doder DD, Djakovic DD (2019) Modeling of intermittent convective drying of walnuts in single layer and its influence on deep bed drying simulation. Therm Sci 23(6):3687–3699

Braun JE, Bansal PK, Groll EA (2002) Energy efficiency analysis of air cycle heat pump dryers. Int J Refrig 25(7):954–965

Chen YX, Lan Q, Ji X, Peng FM, Xia CF, Li XY (2014) Experimental study on heat pump drying characteristics for walnuts. J Yunnan Norm Univ (Nat Sci Ed) 4:30–34

Hao WG, Lu YF, Lai YH, Yu HW, Lv MX (2018) Analysis and application on thermal performance of direct solar drying system. Transactions of the CSAE 34(10):197–193

Orbegoso EM, Saavedra R, Marcelo D, La Madrid R (2017) Numerical characterisation of one-step and three-step solar air heating collectors used for cocoa bean solar drying. J Environ Manage 203:1080–1094

Chen YX (2015) Study on walnut drying by air source heat pump combined with solar energy system. Yunnan Norm Univ

Du ZL, Gao ZJ, Zhang SX (2006) Research on convective heat transfer coefficient with air jet impinging. Transactions of the CSAE A2:1–4

Lao YY, Zhang M, Chitrakar B, Bhandari B, Fan DC (2019) Efficient plant foods processing based on infrared heating. Food Rev Int 35(7):640–663

Chua KJ, Chou SK, Ho JC, Hawlader MNA (2002) Heat pump drying: Recent developments and future trends. Drying Technol 20(8):1579–1610

Ramaswamy H, Tang J (2008) Microwave and radio frequency heating. Food Sci Technol Int 14(5):423–427

Wang S, Tang J, Johnson JA, Mitcham E, Hansen JD, Hallman G, Drake SR, Wang Y (2003) Dielectric properties of fruits and insect pests as related to radio frequency and microwave treatments. Biosys Eng 85(2):201–212

Chua KJ, Mujumdar AS, Chou SK (2003) Intermittent drying of bioproducts-an overview. Biores Technol 90(3):285–295

Zhu DQ, Ma J, Jiang R, Yuan JH, Wang CX, Zhu H (2016) Parameter optimization of hickory nut drying by phased varying power microwave. Transactions of the CSAE 32(15):268–274

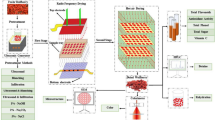

Liu YH, Yang BL, Mao ZH (2010) Radio frequency technology and its application in agro-product and food processing. Transactions of the CSAE 8:115–120

Xie YK, Lin YW, Zhu GF, Yu XL, Xue LY, Gao ZJ, Liu YH (2018) Structure optimization and experiment of radio frequency dryer based on heating uniformity. Transactions of the CSAE 5:248–255

Wang S, Tiwari G, Jiao S, Johnson JA, Tang J (2010) Developing postharvest disinfestation treatments for legumes using radio frequency energy. Biosys Eng 105(3):341–349

Ebrahimzadeh A, Pirzad F, Tahanian H, Aghdam MS (2019) Influence of gum Arabic enriched with GABA coating on oxidative damage of walnut kernels. Food Sci Biotechnol 57(4):554–560

Bujdoso G, Konya E, Berki M, Nagy-Gasztonyi M, Bartha-Szugyi K, Marton B, Izsepi F, Adanyi N (2016) Fatty acid composition, oxidative stability, and antioxidant properties of some Hungarian and other Persian walnut cultivars. Turk J Agric For 40(2):160–168

Wang WQ, Wang HQ, Chen W, Rong RF (2015) Effects of different drying methods on quality of walnuts and stability of unsaturated fatty acids. J Food Sci Technol 33(1):59–64

Luo F, Fei XQ, Guo SH, Du MH (2019) Effects of drying methods on physical and chemical quality of walnut kernel and walnut oil. China oils fats 44(2):8–13

Atungulu GG, Teh HE, Wang T, Fu R, Wang X, Khir R, Pan Z (2013) Infrared pre-drying and dry-dehulling of walnuts for improved processing efficiency and product quality. Appl Eng Agric 29(6):961–971

Zhang B, Zheng AJ, Zhou LY, Huang Z, Wang SJ (2016) Developing hot air-assisted radio frequency drying protocols for in-shell walnuts. Emir J Food Agr 28(7):459–467

Shi JX (2013) Walnut classifier. CN2013101423831

He X (2010) Study on design and experiment of walnut grader. Xinjiang Agri Univ

Yuan L (2006) Experimental research of the dried fruit sorting machine of a grid cylinder. Xinjiang Agri Univ

Shi ZL, Tang XP, Zhao SR, Bai SH, Zhang XJ (2018) Design of grid cylinder type dried fruit sorting machine. Agric Eng 7:105–109

Shen LY, Zhang H, Tang YR, Li Y, Liu Y, Li W (2016) Design and test of walnut cracking machine with self-grading extrusion. Food Mach 7:80–85

Liu MZ, Li CH, Zhang YB, Wang L (2014) Rotary cage-type walnut classifying screen. CN2014100986881

Wang W, He GM, Wang YN (2014) Design and experiments of 3FJ-001 walnut classifier. J Agri Mech Res 5:155–157

Geng AJ, JZ Liu, Z. L. Zhang, J. Zhang (2018) Walnut grading shell breaking machine. CN2018113160172

Rao XQ, Ying YB (2003) Analysis of errors in fruit size inspecting based on machine vision. Transactions of the CSAE 19(1):121–123

Liu JJ, Yao LJ, Peng ZL (2010) Detection technique for cathay hickory grade based on machine vision. Acta Agriculturae Zhejiangensis 6:854–858

Wang W, He GM, Tian ZH, Xu GN (2014) Development of the variable pacing extrusion walnut shell breaking machine. J Chinese Agri Mech 6:174–176

He YC, Cao SL, Wang M, Wang XJ (2012) Squeeze type walnut cracker. CN2012200117789

Dong SH (2011) Study on design and experiment of machine for shell-breaking of walnut multi-roller extrusion. Xinjiang Agri Univ

Shi MC, Feng YP, Feng YT, Jia ZM, Zhao LL, Wang R, Li CH, Wang YC, Zhang YB, Che J, Li RZ, Wang C, Yang M, Hou YL (2019) Multi-station self-adaptive walnut shell pre-breaking system. CN201910734799X

Liu DH (2015) Study on design and experiment of walnut grading and shell-breaking machine. Shanxi Agri Univ

Wang W, He GM, Wang YN, Wang P, Lu JD, Liu DQ, Tian ZH (2019) Flexible shearing, extruding and shell breaking device. CN2019104120151

Zheng X, Cen HL, Tian XY, Chou WX, He J (2019) Hull breaking machine based on pretreated walnuts. CN2019109395818

Liu MZ, Li CH, Zhang YB, Jia DZ, Yang M, Hou YL (2015) Semi-theoretical analyses on mechanical performance of flexible-belt shearing extrusion walnut shell crushing. Appl Eng Agric 32(4):459–467

Hong Y, Yuan PF, Hou YL, Che J, Li CH, Liu MZ, Wang C (2018) Crowded pressure -shear cuts formula walnut shelled device. CN2018203714967

Zhang H, Shen LY, Fan XW, Li Y, Guo WS, Lan HP, Tang YR, Liu YY, Zhou F, Aierwani, Li W (2015) Cusp roll-in formula walnut shelled device. CN2015209521396

Yan R, Zhao KP, Wang YX, Li J, Chen J (2016) Design and test of walnut shell creaking machine with four extrusion forces. Food Mach 32(8):87–91

Li CH, Liu MZ, Wang YC, Zhang YB, Che J, Hou YL, Wang XM, Feng YT, Wang R, Feng YP, Wang HY, Jia ZM, Zhao L, Miao GZ, Li RZ, Gao T (2019) Cam roller type walnut horizontal-squeezing shell-breaking system. CN2019111684977

Zheng JH, Wang YX (2017) Walnut shell breaking device. CN2017102414397

Cao CM, Jiang L, Wu CY, Li Z, Wang TY (2017) Design and test on hammerhead of pecan shell-breaking machine. T Chin Soc Agric Mach 48(10):307–315

Zhu DQ, Cao CM, Fang JW, Jiang JW, Li B, Ding ZY (2010) Experimental research on 6HS-6 type walnut shell cracking equipment. Sci Technol Food Ind 11:304–306

Ding R, Cao CM, Zhan C, Lou SS, Sun S (2013) Design and experiment of bionic-impact type pecan shell breaker. Transactions of the CSAE 33(3):257–264

Shen LY (2017) Design and experimental study on the walnut cracking machine with impact extrusion type. Tarim University

Hou ZL (2019) Research and design of pneumatic extrusion walnut shell-breaking machine. China Academy Agri Mech Sci

Li CH, Xing XD, Ma ZC, Zhang XY, Yang F, Xu HN, Zhou YB, Han YM (2016) Walnut shell smashing device with automatic conveying and positioning functions and method for applying walnut shell smashing device. CN2016102255095

Li WQ, Wang W, Sang ZQ, Wang RJ, Xu JX (2019) Walnut shell breaking device and shell breaking method. CN2019106297457

Wang XX, Shi JX, Zhou J (2013) Design and test of centrifugal secondary broker for walnuts. Xinjiang Agri Sci 6:1115–1121

Cao CM, Li Z, Zhang J, Li S, Fang LF (2017) Centrifugal force-based low-damage hickory nut secondary shell breaking and kernel extracting machine. CN2017100301695

Zhou J (2015) Study on experiment of the method of cracking walnut shell in gas explosion type. Xinjiang Agri Univ

Chen CC (2014) Design and research of impact mountain walnut shell-breaking machine. Shandong Agri Univ

Wang YB, Liu HJ, Chen J, Luo SL, Zhang S (2019) Directional walnut shell breaking equipment. CN2019103048433

Fan XW, Yao FL, Wang ZT, An J, Xu FL, Wang WP, Wu Q (2017) Whole nuclear rejuvenator of walnut classification screw extrusion formula. CN2017210042071

Li XW (2018) Parameters optimization of clearance walnut sheller. Sichuan Agri Univ

Liu MZ (2015) Mechanization analysis and experimentation research of walnut shearing-extrusion flexible shell-crushing. Qingdao Univ Technol

He YC (2010) Study on design and experiment of pneumatic impact cracking machine for walnut. Xinjiang Agri Univ

Song C, Chen CC, Liu XX, Zhang KX (2019) The design of automatically grading and hitting type hickory nut shell breaking machine. J Agri Mech Res 41(9):56–61

Li Z (2019) Design and experiment of secondary shell breaking machine for pecan. Anhui Agri Univ

Liu K, Li ZX, Zhu ZJ, Yang LL, Liu J, Shen XH, Abulizi B, Yang ZQ, Cui KB, Maihemujiang B, Ma WQ (2016) Binary channels independently adjust air separator. CN2016104057262

Wang YN, He GM, Tian ZH, Wang W (2014) Winnowing-type walnut shell-kernel separator. CN2014202694313

Che J, Li CH, Hou YL, Liu MZ, Wang C, Yuan PF, Hong Y (2018) Multi-stage negative-pressure shell and kernel separation equipment. CN2018102201817

Zhang YB, Li CH, Liu MZ, Hou YL (2013) Walnut shell and kernel nest roller vibrating screen wind force separating device. CN2013102335293

Zhu ZJ, Li ZX, Yang LL, Liu K, Abulizi, Liu J, Maihemujiang, Yang ZQ, Shen XH, Tian X, Cui KB, Wang QH, Ma WQ, Yan SK, Ban T, Wang B, Zhu ZS, Mao WL (2015) Air classification formula shuck benevolence sorter. CN2015200408951

Zhang YB, Li CH, Liu MZ (2013) Physical strength and flexible helical blade-coupled walnut shell and kernel drum two-way separation equipment. CN2013106373970

Wang TY (2019) Research on the sorting of hickory nuts shell and kernel based on computer vision. Anhui Agri Univ

Jin FH, Qin L, Jiang L, Zhu B, Tao Y (2008) Novel separation method of black walnut meat from shell using invariant features and a supervised self-organizing map. J Food Eng 88(1):75–85

Cetin AE, Pearson TC, Sevimli RA (2014) System for removing shell pieces from hazelnut kernels using impact vibration analysis. Comput Electron Agric 101:11–16

Liu MZ, Li CH, Zhang YB (2013) Walnut shearing-extrusion shell-breaking, flexible-thrashing and kernel-taking equipment. CN2013106346193

Li ZZ, Cao CM, Li Z, Jiang L, Wang TY, Xie CJ, Fang LG, Sun Y, Ge J (2017) Automated hickory shell breaking and kernel taking production line. CN2017208071663

Dong YD, Zhang XJ, Shi JX (2012) Design and experimental study of walnut shell-kernel winnowing machine. Farm Mach 24:156–158

Chen SJ, Liu YB, Zhang HY, Su J, Heng YW, Feng B, Wu XH (2009) Comparative study on the peeling methods for walnut kernel. Food Eng 4:30–33

Yan PF, Xing SJ, Liu KH, Gao H (2002) Research on the technique of peeling the walnut. Food Sci 1:86–88

Wang WJ, Wang LJ, Feng YM, Pu YF, Ding T, Ye XQ, Liu DH (2018) Ultrasound-assisted lye peeling of peach and comparison with conventional methods. Innov Food Sci Emerg Technol 47:204–213

Fang CC, Kan JQ (2017) Optimization of ultrasonic assisted alkali peeling process of walnut kernel. Sci Technol Food Ind 38(18):195–200

Wen K, Liang SL, Yao ZQ, Hao H, Liu ZL (2009) Study on the processing technology of high protein defatted walnut powder. Sci Technol Food Ind 12:273–276

Zhao C, Liu HP, Yang XX, Gao J, Dong Y, Liu YK, Yan GP, Han ZF (2016) Comparison of nutrient composition between salt liquid method and alkali method to peeling the walnut kernel pellicle. Food Sci Technol 41(6):121–126

Song H (2015) Recovery of walnut flavonoid in peeling wastewater of walnut kernel and itsanti-oxidative activity. Kunming Univ Sci Technol

Wu SL, Qin LK, Jiang CG, Zhang S (2013) Dynamic changes of nutritional and functional components of walnut kernel during lye peeling. China oils fats 2:84–87

Li XF (2005) Study on peeling method of walnut kernel. Food Res Dev 4:37–38

Ling Z, Zhu GF, Xia P, Ren JJ (2014) A new kind of processing technology of walnut comprehensive utilization. Cereals oils proc 12:48–52

Wang L, Wang YQ, Chai XT, Liu MK, Liu XZ, Li J, Gan SY (2019) Peeling of walnut kernel by vacuum freeze-drying: An analytical and experimental study. Chinese J Vac Sci Technol 39(2):103–106

Liu XY, Xue WT (2004) Effect of roasting on flavor and fatty acid oxidation of walnut kernel. China oils fats 29:50–52

Zhang CM, Chen CY, Zhao SL, Huang ZQ, Fan QM (2014) Optimization of extraction technology and in vitro antioxidant activities of polyphenols from walnut kernel pellicle. China Brew 7:130–134

Deng XL, Zhao QZ (2017) Study on conformation and functional properties of walnut protein and its components. Modern Food Sci Technol 33(1):48–53

Li CH, Che J, Xie WD, Zhao QQ, Kang MC, Liu EH, Li ZH, Liu MZ, Wang C (2018) Intelligent device for separating walnut kernels from red coats through principle of thermal expansion and cold contraction, belt transportation and heat radiation. CN2018101411733

Hou YL, Xie WD, Wang C, Li CH, Che J, Zhao QQ, Kang MC, Li D, Liu EH (2017) Roll-over type walnut kernel material spreading, stir-frying and red coating removing device based on electromagnetic heating. CN201711002650X

Pu CW, Kan H, Liu Y (2017) Comparative study of different walnut peeling processes. Farm Products Processing 11:33–35

Liu M (2004) The study on aqueous extraction of oil from walnut kernel and the process of walnut milk. Jiangnan Univ

Rong RF, WU XJ, Li HY, Li LY, Xin Y (2004) Study on the peeling technology for walnut. Sci Technol Food Ind 25(2):100–101

Acknowledgments

This research was financially supported by the National Natural Science Foundation of China (51475002, 51665058, 51865046).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, M., Li, C., Cao, C. et al. Walnut Fruit Processing Equipment: Academic Insights and Perspectives. Food Eng Rev 13, 822–857 (2021). https://doi.org/10.1007/s12393-020-09273-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-020-09273-6