Abstract

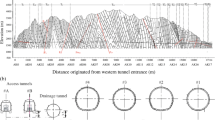

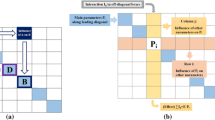

In this paper, the correlations between the different measurements of rock brittleness (i.e., B 1, B 2, B 3, and BI) and the penetration rate (PR) of tunnel boring machine (TBM) through Zagros long tunnel were evaluated. According to the results of simple regression analyses, there was no correlation between the penetration rate of TBM and the brittleness of B 1, but stronger log-linear correlations have been observed between the penetration rate of TBM and the B 2, B 3, and BI brittleness indices. As part of the present study, correlations between some of rock mass classification systems (RQD, RMR, GSI, Q, and Q TBM) and penetration rate of TBM have been investigated. The results of simple regression analyses showed that the first four rock mass classification systems did not exhibit a good correlation with the TBM penetration rate, but the Q TBM had strong correlation with that. Multiple linear regression (MLR) analyses were applied for estimating the TBM penetration rate based on three properties of the rocks (porosity (n), brittleness of B 3, and elastic modulus (E) of intact rock) and rock mass quality system (Q). Also, in this study, artificial neural network (ANN) analyses were applied on the data to develop predictive models for the penetration rate of TBM from porosity, brittleness of B 3, elastic modulus, and Q values. The comparison of the models produced from ANN and MLR analyses using the coefficients of determination showed that the ANN models for predicting the TBM penetration rate were more reliable than the MLR models.

Similar content being viewed by others

References

Altindag R (2002) The evaluation of rock brittleness concept on rotary blast hole drills. J S Afr Inst Min Metal 102(1):61–66

Atkinson PM, Tatnall ARL (1997) Neural networks in remote sensing. Int J Remote Sens 18:699–709

Barton N (2000) TBM tunneling in jointed and faulted rock. Balkema, Rotterdam

Benardos AG, Kaliampakos DC (2004) Modeling TBM performance with artificial neural networks. Tunn Undergr Space Technol 19(3):597–605

Berberian M (1995) Master "blind" thrust faults hidden under the Zagros folds: active basement tectonics and surface morphotectonics. Tectonophysics 241:193–224

Bieniawski ZT, Celada B, Galera JM (2007) TBM Excavability: prediction and machine-rock interaction. In: Proceedings, Rapid Excavation and Tunneling Conference, pp 1118–1130

Blindheim OT (1979) Boreabilty predictions for tunneling. Ph.D. Thesis. Department of geological engineering. The Norwegian Institute of Technology, p. 406

Bruland A (1998) Hard rock tunnel boring. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim

Cassinelli F, Cina S, Innaurato N, Mancini R, Sampaolo A (1982) Power consumption and metal wear in tunnel-boring machines: analysis of tunnel boring operation in hard rock. Tunnelling. London Inst Min Metall 82:73–81

Fowel RJ, McFeat Smith I (1976) Factors influencing the cutting performance of a selective tunneling machine. Tunneling’76, Inst. Of Mining and Metallurgy, UK, pp 3–11

George EA (1995) Brittle failure of rock material – Test results and constitutive models. A.A. Balkema/Rotterdam/Brolkfield, pp 123–128

Ghasemi E, Yagiz S, Ataei M (2014) Predicting penetration rate of hard rock tunnel boring machine using fuzzy logic. Bull Eng Geol Environ 73(1):23–35

Gholamnejad J, Tayarani N (2010) Application of artificial neural networks to the prediction of tunnel boring machine penetration rate. Min Sci Technol 20:0727–0733

Göktan RM (1991) Brittleness and micro-scale rock cutting efficiency. Min Sci Technol 13:237–241

Gong QM, Zhao J, Jiang YS (2007) In situ TBM penetration tests and rock mass boreability analysis in hard rock tunnels. Tunnell Undergr Space Technol 22(3):303–316

Grima MA, Bruines PA, Verhoef PNW (2000) Modeling tunnel boring machine performance by neuro-fuzzy methods. Tunn Undergr Space Technol 15:259–269

Hassanpour J, Rostami J, Khamehchiyan M, Bruland A, Tavakoli HR (2009) TBM performance analysis in pyroclastic rocks: a case history of Karaj water conveyance tunnel. Rock Mech Rock Eng 43:427–445

Heidari M, Khanlari GR, Torabi Kaveh M, Kargarian S, Saneie S (2014) Effect of porosity on rock brittleness. Rock Mech Rock Eng 47:785–790

Howarth DF, Adamson WR, Berndt RJ (1986) Correlation of model tunnel boring and drilling machine performances with rock properties. Int J Rock Mech Min Sci 23(2):171–175

Hucka V, Das B (1974) Brittleness determination of rocks by different methods. Int J Rock Mech Min Sci Geomech Abstr 11:389–392

Sahel and Imensazan Consulting Engineers Companies (2008) Engineering geology report concerning Zagros long tunnel route, Zagros long tunnel project, Teheran, Iran (in Persian)

Innaurato N, Mancini R, Rondena E, Zaninetti A (1991) Forecasting and effective TBM performances in a rapid excavation of a tunnel in Italy. In: Proceedings of the Seventh International Congress ISRM, Aachen, pp 1009–1014

Kahraman S (2002) Correlation of TBM and drilling machine performances with rock brittleness. Eng Geol 65:269–283

Karakus M, Kumral M, Kilic O (2005) Predicting elastic properties of intact rocks from index tests using multiple regression modeling. Int J Rock Mech Min Sci 42(2):323–330

Karimi-Bavandpur A, HajiHoseini A (1999) Geological map of Kermanshah, Geological Survey of Iran (GSI) 1:100,000

Khademi Hamidi J, Shahriar K, Rezai B, Rostami J (2010) Performance prediction of hard rock TBM using rock mass rating (RMR) system. Tunn Undergr Space Technol 25:333–345

Khandelwal M, Roy MP, Singh PK (2004) Application of artificial neural network in mining industry. Indian Min Eng J 43(7):19–23

Mansouri M, Moomivand H (2010) Influence of rock mass properties on TBM penetration rate in Karaj-Tehran water conveyance tunnel. J Geol Min Res 2(5):114–121

Martins FF, Miranda TFS (2013) Prediction of hard rock TBM penetration rate based on Data Mining techniques. Proceedings of the 18th International Conference on Soil Mechanics and Geotechnical Engineering, Paris

McFeat Smith I (1977) Rock property testing for the assessment of tunneling machine performance. Tunnels and Tunneling, 29–33

Mikaeil R, Zare M, Sereshki F (2009) Multifactorial fuzzy approach to the penetrability classification of TBM in hard rock conditions. Tunn Undergr Space Technol 24(3):500–505

Okubo S, Fukui K, Chen W (2003) Expert system for applicability of tunnel boring machines in Japan. Rock Mech Rock Eng 36(4):305–322

Oraee K, Salehi B (2013) Assessing prediction models of advance rate in tunnel boring machines—a case study in Iran. Arab J Geosci 6:481–489

Oraee K, Khorami MT, Hosseini N (2012) Prediction of the penetration rate of TBM using adaptive neuro fuzzy inference system (ANFIS). Proceeding of SME Annual Meeting & Exhibit, From the Mine to the Market, Now It's Global, Seattle, WA, USA, pp. 297–302

Ozdemir L (1977) Development of theoretical equations for predicting tunnel borability. Ph.D. Thesis, T-1969, Colorado School of Mines, Golden, CO, USA

Palmstrom A (1995) RMi—a rock mass characterization system for rock engineering purposes. Ph.D. Thesis, University of Oslo, p 400

Pang SS, Goldsmith W, Hood M (1989) A force-indentation model for brittle rocks. Rock Mech Rock Eng 22:127–148

Protodyakonov MM (1963) Mechanical properties and drillability of rocks. In: Proceedings of the 5th Symposium Rock Mechanics, University of Minnesota, pp 103–118

Ramamurthy T (2008) Penetration rate of TBMs. World Tunnel Congress 2008 - Underground Facilities for Better Environment and Safety – India

Ribacchi R, Lembo Fazio A (2005) Influence of rock mass parameters on the performance of a TBM in a gneissic formation (Varzo Tunnel). Rock Mech Rock Eng 38(2):105–127

Roxborough FF, Phillips HR (1975) Rock excavation by disc cutter. Int J Rock Mech Min Sci Geomech Abstr 12:361–366

Salimi A, Esmaeili M (2013) Utilising of linear and non-linear prediction tools for evaluation of penetration rate of tunnel boring machine in hard rock condition. Int J Min Min Eng 4(3):249–264

Sapigni N, Berti M, Behtaz E, Busillo A, Cardone G (2002) TBM performance estimation using rock mass classification. Int J Rock Mech Min Sci 39:771–788

Singh SP (1985) Brittleness and the mechanical winning of coal. Min Sci technol 338:173–180

Torabi SR, Shirazi H, Hajali H, Monjezi M (2013) Study of the influence of geotechnical parameters on the TBM performance in Tehran–Shomal highway project using ANN and SPSS. Arab J Geosci 6:1215–1227

Yagiz S (2008) Utilizing rock mass properties for predicting TBM performance in hard rock condition. Tunn Undergr Space Technol 23:326–339

Yagiz S (2009) Assessment of brittleness using rock strength and density with punch penetration test. Tunn Undergr Space Technol 24:66–74

Yagiz S, Gokceoglu C (2010) Application of fuzzy inference system and nonlinear regression models for predicting rock brittleness. Expert Syst Appl 37:2265–2272

Yagiz S, Karahan H (2011) Prediction of hard rock TBM penetration rate using particle swarm optimization. Int J Rock Mech Min Sci 48:427–433

Yagiz S, Rostami J, Ozdemir L (2008) Recommended rock testing methods for predicting TBM performance: focus on the CSM and NTNU Models. In: Proceedings of 5th Asian Rock Mechanics Symposium, Tehran, Iran

Yagiz S, Gokceoglu C, Sezer E, Iplikci S (2009) Application of two non-linear prediction tools to the estimation of tunnel boring machine performance. Eng Appl Artif Intell 22:808–814

Yoo C, Kim J (2007) Tunneling performance prediction using an integrated GIS and neural network. Comput Geotech 34:19–30

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohammadi, S.D., Torabi-Kaveh, M. & Bayati, M. Prediction of TBM penetration rate using intact and mass rock properties (case study: Zagros long tunnel, Iran). Arab J Geosci 8, 3893–3904 (2015). https://doi.org/10.1007/s12517-014-1465-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12517-014-1465-0