Abstract

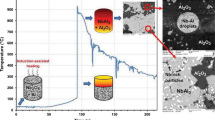

Of various systems that utilize a self-propagating high-temperature synthesis, the Al-TiO2-C system is representative of in-situ production of metal matrix composites reinforced with TiC and Al2O3. Contrary to common understanding, however, the following reaction 4Al + 3TiO2 + 3C→3TiC + 2Al2O3 is infeasible in the Al-TiO2-C system with the given stoichiometric composition of 4Al + 3TiO2 + 3C. Experiments have shown that the formation of TiC and Al2O3 is feasible only in an Al-TiO2-C system that contains a certain amount of excess Al. In this study, the mechanism of the reactions in the Al-TiO2-C system was elucidated in order to explain why excess Al is needed to promote the formation of TiC and Al2O3. We also estimated the amount of excess Al that is necessary to promote the complete transformation of the Al-TiO2-C powders to TiC and Al2O3.

Similar content being viewed by others

References

B. Yang, M. Sun, G. Gan, C. Xu, and Z. Huang, J. Alloys Comp. 494, 261 (2010)

Q. Y. Hou, Surf. Coat. Technol. 226, 113 (2013).

V. P. Kobyakov and T. V. Barlnova, Inorganic Materials. 45, 211 (2009).

T. D. Xia, Z. A. Munir, Y. L. Tang, W. J. Zhao, and T. M. Wang, J. Am. Ceram. Soc. 83, 507 (2000).

S. Kleiner and F. Bertocco, Mater. Chem. Phys. 89, 362 (2005).

H. Chia-Wen and C. Chuen-Guang, Metall. Mater. Trans. B. 33B, 31 (2002).

S. O. Chwa and D. Klein, Surf. Coat. Technol. 194, 215 (2005).

P. C. Maity, S. C. Panigrahi, and P. N. Chakraborty, Scripta Metall. Mater. 28, 549 (1993).

I. Gheorghe and H. J. Rack, Metall. Mater. Trans. A. 33A, 2155 (2002).

Q. Zhang, B. L. Xiao, W. G. Wang, and Z. Y. Ma, Acta Mater. 60, 7090 (2012).

L. Lu, M. O. Lai, Y. Su, H. L. Teo, and C. F. Feng, Scripta Mater. 45, 1017 (2001).

C. F. Feng and L. Froyen, Scripta Mater. 36, 467 (1997).

E. M. Sharifi, F. Karimzadeh, and M. H. Enayati, J. Alloys Comp. 502, 508 (2010).

J. H. Lee, S. K. Ko, and C. W. Won, Mater. Research Bulletin, 36, 1157 (2001).

B. Yang, G. Chen, and J. Zhang, Mater. Design. 22, 645 (2001).

Z. Wang and X. Liu, J. Mater. Sci. 40, 1047 (2005).

P. Li, E. G. Kandalova, V. I. Nikitin, A. G. Makarenko, A. R. Luts, and Z. Yanfei, Scripta Mater. 49, 699 (2003).

I. Kerti, Mater. Lett. 59, 3795 (2005).

G. Golkar, S. M. Zebarjad, and J. V. Khaki, J. Alloys Comp. 504, 566 (2010).

T. D. Xia, T. Z. Liu, W. J. Zhao, and B. Y. Ma, J. Mater. Sci. 36, 5581 (2001).

P. Yu, Z. Mei, and S. C. Tjong, Mater. Chem. Phys. 93, 109 (2005).

S. K. Mishra, S. K. Das, and V. Sherbacov, Comp. Sci. Tech. 67, 2447 (2007).

H. Zhu, C. Jia, J. Li, J. Zhao, J. Song, Y. Yao, and Z. Xie, Powder Tech. 217, 401 (2012).

Z. Wang and X. Liu, J. Mater. Sci. 40, 4727 (2005).

Q. Dong, Q. Tang, W. C. Li, and D. Y. Wu, Mater. Lett. 55, 259 (2002).

H. Zhu, J. Min, Y. Ai, D. Chu, and H. Wang, Mater. Sci. Eng. A. 527, 6178 (2010).

X. C. Tong and H. S. Fang, Metall. Mater. Trans. A. 29A, 875 (1998).

X. C. Tong and H. S. Fang, Metall. Mater. Trans. A. 29A, 893 (1998).

M. S. Song, M. X. Zhang, S. G. Zhang, B. Huang, and J. G. Li, Mater. Sci. Eng. A. 473, 166 (2008).

Z. Wang, X. Liu, J. Zhang, and X. Bian, J. Mater. Sci. 39, 667 (2004).

J. H. Lee, S. K. Ko, and C. W. Won, Mate. Res. Bull. 36, 1157 (2001).

H. Zhu, Y. Jiang, Y. Yao, J. Song, J. Li, and Z. Xie, Mater. Chem. Phys. 137, 532 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, JW., Lee, JM., Lee, JH. et al. Role of excess Al on the combustion reaction in the Al-TiO2-C system. Met. Mater. Int. 20, 1151–1156 (2014). https://doi.org/10.1007/s12540-014-6020-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-014-6020-8