Abstract

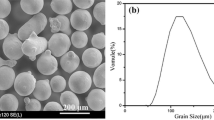

This study focuses on the mechanical characteristics of layered tool steel deposited using direct energy deposition (DED) technology. In the DED technique, a laser beam bonds injected metal powder and a thin layer of substrate via melting. In this study, AISI D2 substrate was hardfaced with AISI H13 and M2 metal powders for mechanical testing. The mechanical and metallurgical characteristics of each specimen were investigated via microstructure observation and hardness, wear, and impact tests. The obtained characteristics were compared with those of heat-treated tool steel. The microstructures of the H13- and M2-deposited specimens show fine cellular-dendrite solidification structures due to melting and subsequent rapid cooling. Moreover, the cellular grains of the deposited M2 layer were smaller than those of the H13 structure. The hardness and wear resistance were most improved in the M2-deposited specimen, yet the H13-deposited specimen had higher fracture toughness than the M2-deposited specimen and heat-treated D2.

Similar content being viewed by others

References

S. D. Sun, Q. Liu, M. Brandt, V. Luzin, R. Cottam, M. Janardhana, et al. Mat. Sci. Eng. A 606, 46 (2014).

N.-R. Park and D.-G. Ahn, Int. J. Precis. Eng. Man. 15, 2549 (2014).

S. H. Wang, J.-Y. Chen, and L. Xue, Surf. Coat. Technol. 200, 3446 (2006).

J. S. Park, M.-G. Lee, Y.-J. Cho, J. H. Sung, M.-S. Jeong, D. H. Kim, et al. Met. Mater. Int. 22, 143 (2016).

M. Pleterski, T. Muhič, B. Podgornik, and J. Tušek, Eng. Fail. Anal. 18, 1527 (2011).

D. Boisselier and S. Sankaré, Phys. Procedia. 39, 455 (2012).

Y. Chew and J. H. L. Pang, Int. J. Fatigue 87, 235 (2016).

J. H. Jang, B. D. Joo, S. M. Mun, M. Y. Sung, and Y. H. Moon, Met. Mater. Int. 17, 167 (2011).

J. S. Kim, C.-M. Chung, S.-H. Baik, and S.-B. Lee, Met. Mater. Int. 17, 77 (2011).

D. Das, R. Sarkar, A. K. Dutta, and K. K. Ray, Mat. Sci. Eng. A 528, 589 (2010).

D. Cong, H. Zhou, Z. Ren, Z. Zhang, H. Zhang, C. Meng, et al. Mater. Design 55, 597 (2014).

J. M. Torralba, L. E. G. Cambronero, J. M. Ruiz-Prieto, and M. M. das Neves, Powder Metall. 36, 55 (1993).

C.-M. Kwon, G.-G. Lee, and G.-H. Ha, Korean J. Met. Mater. 54, 10 (2016).

A. Medvedeva, J. Bergström, S. Gunnarsson, and J. Andersson, Mat. Sci. Eng. A 523, 39 (2009).

S.-W. Choi, K.-H. Lee, J. Suh, M.-H. Oh, and C.-Y. Kang, Korean J. Met. Mater. 54, 3 (2016).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baek, G.Y., Shin, G.Y., Lee, E.M. et al. Mechanical characteristics of a tool steel layer deposited by using direct energy deposition. Met. Mater. Int. 23, 770–777 (2017). https://doi.org/10.1007/s12540-017-6442-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-017-6442-1