Abstract

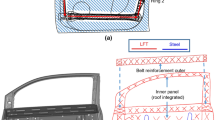

To support the latest automobile technology, the next generation of diesel engines is expected to require higher injection pressures than the third generation which can operate at high injection pressures up to 1,800bar. A component in the common rail system, the common rail pipe must have higher strength because it is directly influenced by the high-pressure fuel. Preform design is very important for preventing the head of the common rail pipe from folding in the heading process. In this study, the angle, curvature and outer diameter of the die and the length of the trapped part are selected as main parameters in the design of the optimal preform shape that minimizes the radius of folding. The optimal design is carried out by finite element analysis and the Taguchi method using the main parameters and then fatigue-life analysis is preformed for predicting fatigue life according to the amount of folding. Also, a closed form equation to predict fatigue life was suggested by Goodman theory and life-prediction method for pressure vessels pursuant to ASME Code. In order to verify the reliability of common rail pipe, fatigue-structural coupled field analysis is performed. The results of the finite element analysis were in good agreement with those of the experiments at the actual site and theoretical analysis.

Similar content being viewed by others

References

Flaig, U., Polach, W. and Ziegler, G., “Common rail system (CR-system) for passenger car DI diesel engines; Experiences with applications for series production projects,” SAE Paper No. 1999-01-0191, 1999.

Wang, Z., Lu, J. and Wang, Z. R., “Numerical and experimental research of the cold upsetting-extruding of tube flanges,” Journal of Material Processing Technology, Vol. 110, No. 1, pp. 28–35, 2001.

Hua, X. L. and Wang, Z. R., “Numerical simulation and experimental study on the multi-step upsetting of a thick and wide flange on the end of a pipe,” Journal of Material Processing Technology, Vol. 151, No. 1–3, pp. 321–327, 2004.

Lin, S. Y., “Analysis of the Dissimilar Interface Frictional Constraints during the Upsetting Process,” International Journal of Advanced Manufacturing Technology, Vol. 13, No. 9, pp. 601–610, 1997.

Lee, E. W., “Fatigue Analysis of Pressure Vessles pursuant to ASME Code,” Transactions of Korean Society of Steel Construction, Vol. 8, No. 1, pp. 32–38, 1996.

Han, S. M., Hwang, B. C., Kim, H. Y. and Kim, C., “Analysis of the Autofrettage Effect in Improving the Fatigue Resistance of Automotive CNG Storage Vessels,” Int. J. Precis. Eng. Manuf., Vol. 10, No. 1, pp. 15–21, 2009.

ISO/CD 13296, “Diesel engines — High pressure fuel injection pipe assemblies — General requirements and dimensions,” 2005.

Poursina, M., Parvizian, J. and Antonio, C. A. C., “Optimum pre-form dies in two-stage forging,” Journal of Material Processing Technology, Vol. 174, No. 1–3, pp. 325–333, 2006.

Moe, P. T., Abtahi, S., Ganesan, S. M., Støren, S. and Rudd, W., “Optimization of a pipe end upsetting process,” International Journal of Material Forming, Vol. 1, No. 1, pp. 13–16, 2008.

Sheu, J. J. and Yu, C. H., “Preform and forging process designs based on geometrical features using 2D and 3D FEM simulations,” International Journal of Advanced Manufacturing Technology, Vol. 44, No. 3–4, pp. 244–254, 2008.

Gökler, M. I., Darendeliler, H. and Elmaskaya, N., “Analysis of tapered preforms in cold upsetting,” International Journal of Machine Tools and Manufacture, Vol. 39, No. 1, pp. 1–16, 1999.

Ross, P. J., “Taguchi techniques for quality engineering: loss function, orthogonal experiments, parameter and tolerance design, 2nd Edition,” McGraw-Hill, 1996.

Li, B., Nye, T. J. and Metzger, D. R., “Multi-objective optimization of forming parameters for tube hydroforming process based on the Taguchi method,” International Journal of Advanced Manufacturing Technology, Vol. 28, No. 1–2, pp. 23–30, 2006.

Lee, Y. B., “Introduction to Fatigue Analysis,” Cheongmoongak, pp. 30–31, 2005.

Kim, H. Y., Hwang, B. C., Bae, W. B., Han, S. M. and Kim, C., “Analysis of an Autofrettage Effect to Improve Fatigue Life of the Automotive CNG Storage Vessel,” Korean Society for Technology of Plasticity, Vol. 17, No. 4, pp. 292–301, 2008.

Stephens, R. I., Fatemi, A., Stephens, R. R. and Fuchs, H. O., “Metal Fatigue in Engineering, 2nd ed.,” John Wiley and Sons Inc, pp. 197–198, 2001.

Pilkey, W. D., “Peterson’s stress concentration factors, 2nd ed.,” John Wiley and Sons Inc., p. 436, 1997.

Bishop, N. W. M. and Sherratt, F., “Finite element based fatigue calculations,” NAFEMS, pp. 31–33, 2000.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bae, JH., Kim, MS., Song, MJ. et al. A study on optimal design and fatigue life of the common rail pipe. Int. J. Precis. Eng. Manuf. 12, 475–483 (2011). https://doi.org/10.1007/s12541-011-0061-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-011-0061-4