Abstract

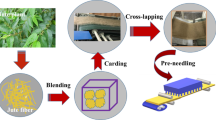

Aiming at the green manufacturing technology of automotive industry, in the past, some researchers have developed green materials—fully degradable natural fiber reinforced polylactide composites. In the researches, the natural fiber volume fraction (or weight fraction) ranges from 20% to 55%. In order to lower the cost of the composites, an effective way is to increase natural fiber volume fraction and decrease polylactide fraction. In this research, a more uniform fiber blending method is employed, and the natural fiber volume fraction is increased to 70%. The fabrication process includes two steps: felt making and hot pressed molding. Short jute fiber and short PLA fiber are blended on a fiber opening machine in terms of fiber volume fractions, 60% and 70% respectively. The mixtures are carded and needle punched to make felt. Then the felt is hot pressed at 180 °C, and the jute/PLA composites are fabricated. Mechanical properties of the composites with different fiber volume fractions are investigated. Real size truck liners are successfully manufactured. The composites have very good formability and processability.

Similar content being viewed by others

References

Kang, Y. C., Chun, D. M., Jun, Y., and Ahn, S. H., “Computeraided Environmental Design System for the Energy-using Product (EuP) Directive,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 3, pp. 397–406, 2010.

Ray, S. S. and Bousmina, M., “Biodegradable Polymers and Their Layered Silicate Nanocomposites: In Greening the 21st Century Materials World,” Prog. Mater. Sci., Vol. 50, No. 8, pp. 962–1079, 2005.

Hu, R. H., Sun, M. Y., and Lim, J. K., “Moisture Absorption, Tensile Strength and Microstructure Evolution of Short Jute Fiber/Polylactide Composite in Hygrothermal Environment,” Mater. Design, Vol. 31, No. 7, pp. 3167–3173, 2010.

Park, C. W., Kwon, K. S., Kim, W. B., Min, B. K., Park, S. J., Sung, I. H., Yoon, Y. S., Lee, K. S., Lee, J. H., and Seok, J., “Energy Consumption Reduction Technology in Manufacturing — A Selective Review of Policies, Standards, and Research,” Int. J. Precis. Eng. Manuf., Vol. 10, No. 5, pp. 151–173, 2009.

Jeon, K. W., Shin, K. B., and Kim, J. S., “Evaluation of Tension-Compression and Tension-Tension Fatigue Life of Woven Fabric Glass/Epoxy Laminate Composites used in Railway Vehicle,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 5, pp. 813–820, 2011.

Hu, R. H. and Lim, J. K., “Fabrication and Mechanical Properties of Completely Biodegradable Hemp Fiber Reinforced Polylactic Acid Composites,” J. Comp. Mater., Vol. 41, No. 13, pp. 1655–1669, 2007.

Graupner, N., Herrmann, A. S., and Mussig, J., “Natural and Man-made Cellulose Fibre-reinforced Poly (lactic acid) (PLA) Composites: An Overview about Mechanical Characteristics and Application Areas,” Comp. Part A: Applied Science and Manufacturing, Vol. 40, No. 6–7, pp. 810–821, 2009.

Graupner, N., “Improvement of the Mechanical Properties of Biodegradable Hemp Fiber Reinforced Poly (lactic acid) (PLA) Composites by the Admixture of Man-made Cellulose Fibers,” J. Comp. Mater., Vol. 43, No. 6, pp. 689–702, 2009.

Reddy, K. O., Maheswari, C. U., Rajulu, A. V., and Guduri, B. R., “Thermal Degradation Parameters and Tensile Properties of Borassus flabellifer Fruit Fiber Reinforcement,” J. Reinf. Plast. Comp., Vol. 28, No. 18, pp. 2297–2301, 2009.

Chen, F., Liu, L. S., Cooke, P. H., Hicks, K. B., and Zhang, J., “Performance Enhancement of Poly (lactic acid) and Sugar Beet Pulp Composites by Improving Interfacial Adhesion and Penetration,” Ind. Eng. Chem. Res., Vol. 47, No. 22, pp. 8667–8675, 2008.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, RH., Ma, ZG., Zheng, S. et al. A fabrication process of high volume fraction of jute fiber/polylactide composites for truck liner. Int. J. Precis. Eng. Manuf. 13, 1243–1246 (2012). https://doi.org/10.1007/s12541-012-0165-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0165-5