Abstract

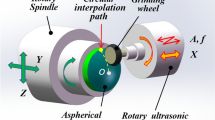

Vibration-assisted grinding, in which harder abrasives than materials to be machined are employed, has been a viable and effective approach to increasing material removal rate (MRR) and/or reducing surface roughness of ground surfaces. We transfer this ideology to fused silica polishing by incorporating ultrasonic vibration into recently developed fixed-abrasive pellets in an attempt to enhance MRR and/or to improve manufactured surface quality. A prototype ultrasonic vibrator, the heart of the polishing head, was designed and the related experimental work was performed on an in-house built setup in conjunction with the constructed head. The vibrator is devised for the generation of 2-D tool path despite using only one actuator in lieu of two actuators in conventional 2-D ultrasonic machining systems. We then combined the ultrasonic vibration with fixed abrasive polishing pellets to machine fused silica glass. Machining experiments reveal that MRR is considerably increased up to >50% upon the introduction of ultrasonic vibration (UV) whilst surface roughness is not degraded appreciably. It was also noted that a overwhelmingly greater deal of polishing debris was dispelled during ultrasonic vibration assisted polishing than conventional bound-abrasive polishing, which may account for the greater MRR in UV assisted polishing.

Similar content being viewed by others

References

French, R. and Tran, H., “Immersion lithography: Photomask and wafer-level materials,” Annu. Rev. Mater. Res., Vol. 39, pp. 93–126, 2009.

Campbell, J. H., Hawley-Fedder, R. A., Stolz, C. J., Menapace, J. A., Borden, M. R., Whitman, P. K., Yu, J., Runkel, M. J., Riley, M. O., Feit, M. D., and Hackel, R. P., “NIF optical materials and fabrication technologies: An overview,” Proc. SPIE, Vol. 5341, pp. 84–101, 2004.

Choi, J. H., Zoulkarneev, A., Kim, S., Baik, C., Yang, H., Park, S., Suh, H., Kim, U., Son, H., Lee, J., Kim, M., Kim, J., and Kim, K., “Nearly single-crystalline GaN light-emitting diodes on amorphous glass substrates,” Nature Photonics, Vol. 5, No. 12, pp. 763–769, 2011.

Bloembergen, N., “Role of cracks, pores, and absorbing inclusions on laser induced damage threshold at surfaces of transparent dielectrics,” Appl. Opt., Vol. 12, No. 4, pp. 661–664, 1973.

Parham, T. G., Stolz, C., Baisden, T., Kozlowski, M., Kiikka, C., and Aikens, D. M., “Developing optics finishing technologies for the national ignition facility,” ICF Quarterly Report, Vol. 9, pp. 177–191, 1999.

Tesar, A. A., Fuchs, B. A., and Hed, P. P., “Examination of the polished surface character of fused silica,” Appl. Opt., Vol. 31, No. 34, pp. 7164–7172, 1992.

Ando, M., Negishi, M., Takimoto, M., Deguchi, A., and Nakamura, N., “Super-smooth polishing on aspherical surfaces,” Nanotechnology, Vol. 6, No. 4, pp. 111–120, 1995.

Leistner, A. J., Thwaite, E. G., Lesha, F., and Bennett, J. M., “Polishing study using Teflon and pitch laps to produce flat and supersmooth surfaces,” Appl. Opt., Vol. 31, No. 10, pp. 1472–1482, 1992.

Hed, P. P., “Calculations of material removal, removal rate and Preston coefficient in continuous lapping/polishing machines,” Lawrence Livermore National Laboratory Report, UCRL-ID-115321, 1993.

Tesar, A. and Fuchs, B. A., “Removal rates of fused silica with cerium oxide/pitch polishing,” Proc. SPIE, Vol. 1531, pp. 80–90, 1992.

Golini, D. and Jacobs, S. D., “Physics of loose abrasive microgrinding,” Appl. Opt., Vol. 30, No. 19, pp. 2761–2777, 1991.

Evans, C. J., Paul, E., Dornfeld, D., Lucca, D. A., Byrne, G., Tricard, M., Klocke, F., Dambon, O., and Mullany, B. A., “Material removal mechanisms in lapping and polishing,” CIRP Ann., Vol. 52, No. 2, pp. 611–633, 2003.

Desai, J. N., “Advances and processes in precision glass polishing techniques,” Report of the University of Florida, 2009.

Berggren, R. R. and Schmell, R. A., “Pad polishing for rapid production of large flats,” Proc. SPIE, Vol. 3134, pp. 252–257, 1997.

Li, Y., Hou, J., Xu, Q., Wang, J., Yang, W., and Guo, Y., “The characteristics of optics polished with a polyurethane pad,” Opt. Express, Vol. 16, No. 14, pp. 10285–10293, 2008.

Mun, S.-D., “Micro machining of high-hardness materials using magnetic abrasive grains,” Int. J. Precis. Eng. Manuf., Vol. 11, No. 5, pp. 763–770, 2010.

Kordonski, W. I. and Jacobs, S. D., “Magnetorheological finishing,” Int. J. Mod. Phys. B, Vol. 10, No. 23–24, pp. 2837–2848, 1996.

Mirian, S., Safavi, M., Fadaei, A., Salimi, M., and Farzin, M., “Improving the quality of surface in polishing process with the magnetic abrasive powder polishing (MAPP) by use of ultrasonic oscillation of work-piece on a CNC table,” Int. J. Precis. Eng. Manuf., Vol. 12, No. 2, pp. 275–284, 2011.

Walker, D., Brooks, D., King, A., Freeman, R., Morton, R., McCavana, G., and Kim, S.-W., “The ‘Precessions’ tooling for polishing and figuring flat, spherical and aspheric surfaces,” Opt. Express, Vol. 11, No. 8, pp. 958–964, 2003.

Kulawski, M., Henttinen, K., Suni, I., Weimar, F., and Makinen, J., “A novel CMP process on fixed abrasive pads for the manufacturing of highly planar thick film SOI substrates,” Mat. Res. Soc. Proc., Vol. 767, pp. 133–139, 2003.

Ochiai, K., Nanbu, Y., Tanaka, F., Sasaki, T., and Utsunomiya, Y., “Study on high-removal-rate mirror grinding of optical glass,” Research Report of Saitama Industrial Technology Center, Vol. 8, pp. 78–83, 2009. (in Japanese)

Bifano, T. G., Dow, T. A., and Scattergood, R. O., “Ductile-regime grinding: a new technology for machining brittle materials,” Trans. ASME J. Eng. Ind., Vol. 113, No. 2, pp. 184–189, 1991.

Ngoi, B. and Sreejith, P., “Ductile regime finish machining-a review,” Int. J. Adv. Manuf. Technol., Vol. 16, No. 8, pp. 547–550, 2000.

Biffano, T., DePiero, D. K., and Golini, D., “Chemomechanical effects in ductile-regime machining of glass,” Prec. Eng., Vol. 15, No. 4, pp. 238–247, 1993.

Brehl, D. E. and Dow, T. A., “Review of vibration-assisted machining,” Prec. Eng., Vol. 32, No. 3, pp. 153–172, 2008.

Markov, A. I., “Ultrasonic machining of intractable materials,” (Mashgiz, Moscow, U.S.S.R.,) 1962 (in Russian) [translated by Scripta Technica Ltd., edited by Neppiras, E. A., Iliffe Books Ltd.] Chapter 2, 1966.

Guzzo, P. L., Shinohara, A. H., and Raslan, A. A., “A comparative study on ultrasonic mchining of hard and brittle materials,” J. Braz. Soc. Mech. Sci. Eng., Vol. 26, No. 1, pp. 56–61, 2004.

Pei, Z. J. and Ferreira, P. M., “Modeling of ductile-mode material removal in rotary ultrasonic machining,” Int. J. Mach. Tool. Manuf., Vol. 38, No. 10–11, pp. 1399–1418, 1998.

Moriwaki, T., Shamoto, E., and Inoue, K., “Ultraprecision ductile cutting of glass by applying ultrasonic vibration,” Ann. CIRP, Vol. 41, No. 1, pp. 141–144, 1992.

Zhou, M., Wang, X. J., Ngoi, B., and Gan, J., “Brittle-ductile transition in the diamond cutting of glasses with the aid of ultrasonic vibration,” J. Mater. Process. Technol., Vol. 121, No. 2–3, pp. 243–251, 2002.

Qu, W., Wang, K., Miller, M. H., Huang, Y., and Chandra, A., “Using vibration-assisted grinding to reduce subsurface damage,” Prec. Eng., Vol. 24, No. 4, pp. 329–337, 2000.

Nath, C. and Rahman, M., “Effect of machining parameters in ultrasonic vibration cutting,” Int. J. Mach. Tool. Manuf., Vol. 48, No. 9, pp. 965–974, 2008.

Zhou, M., Ngoi, B., Yusoff, M., and Wang, X. J., “Tool wear and surface finish in diamond cutting of optical glass,” J. Mater. Process. Technol., Vol. 174, No. 1–3, pp. 29–33, 2006.

Egashira, K. and Masuzawa, T., “Microultrasonic machining by the application of workpiece vibration,” Ann. CIRP, Vol. 48, No. 1, pp. 131–134, 1999.

Tsai, M.-Y. and Yang, W.-Z., “Combined ultrasonic vibration and chemical mechanical polishing of copper substrates,” Int. J. Mach. Tool. Manuf., Vol. 53, No. 1, pp. 69–76, 2012.

Xu, W., Lu, X., Pan, G., Lei, Y., and Luo, J., “Ultrasonic flexural vibration assisted chemical mechanical polishing for sapphire substrate,” Appl. Suf. Sci., Vol. 256, No. 12, pp. 3936–3940, 2010.

Tso, P.-L. and Tung, C., “Study on ultrasonic-assisted chemical mechanical polishing,” Int. J. Abra. Technol., Vol. 4, No. 2, pp. 132–139, 2011.

Gillman, B. E. and Jacobs, S. D., “Bound-abrasive polishers for optical glass,” Appl. Opt., Vol. 37, No. 16, pp. 3498–3505, 1998.

Bastawros, A., Chandra, A., Guo, Y., and Yan, B., “Pad effects on material-removal rate in chemical-mechanical planarization,” J. Electro. Mater., Vol. 31, No. 10, pp. 1022–1031, 2002.

Wang, C., Sherman, P., Chandra, A., and Dornfeld, D., “Pad surface roughness and slurry particle size distribution effects on material removal rate in chemical mechanical planarization,” Ann. CIRP, Vol. 54, No. 1, pp. 309–312, 2005.

Luo, J. and Dornfeld, D. A., “Optimization of CMP from the viewpoint of consumable effects,” J. Electrochem. Soc., Vol. 150, No. 12, pp. G807–G815, 2003.

Kachalov, N. N., “Technology of grinding and polishing sheet glass,” (Acad. Sci., Moscow-Leningrad), 1958 (in Russian) [translated by Mao, W. and Yang, Y., China Industry Press, Peking] Chapter 4, 1965. (in Chinese)

Wang, L., Zhang, K., Song, Z., and Feng, S., “Ceria concentration effect on chemical mechanical polishing of optical glass,” Appl. Surf. Sci., Vol. 253, No. 11, pp. 4951–4954, 2007.

Luo, J. and Dornfeld, D. A., “Material removal regions in chemical mechanical planarization for submicron integrated circuit fabrication: Coupling effects of slurry chemicals, abrasive size distribution, and wafer-pad contact area,” IEEE Trans. Semicond. Manuf., Vol. 16, No. 1, pp. 45–56, 2003.

Bulsara, V. H., Ahn, Y., Chandrasekar, S., and Farris, T. N., “Mechanics of polishing,” Trans. ASME: J. Appl. Mech., Vol. 65, No. 2, pp. 410–416, 1998.

Gagliardi, J., Zagrebelny, A., Joseph, B., and Zazzera, L., “Advancements for sub 45 nm fixed abrasive STI CMP, NCCAVS CMP Users Group at Semicon West Moscone Center,” San Francisco, C.A., USA, 2007.

Rogov, V. V., Filatov, Y., Kottler, W., and Sobol, V. P., “New technology of precision polishing of glass optics,” Opt. Eng., Vol. 40, No. 8, pp. 1641–1645, 2001.

Filatov, Y. D., Filatov, O., Y., Monteil, G., Heisel, U., and Storchak, M., “Bound-abrasive grinding and polishing of surfaces of optical materials,” Opt. Eng., Vol. 50, No. 6, pp. 063401, 2011.

Zhou, L., Eda, H., Shimizu, J., Kamiya, S., Iwase, H., Kimura, S., and Sato, H., “Defect-free fabrication for single crystal silicon substrate by chemo-mechanical grinding,” Ann. CIRP, Vol. 55, No. 1, pp. 313–316, 2006.

Zhou, L., Shiina, T., Qiu, Z., Shimizu, J., Yamamoto, T., and Tashiro, T., “Research on chemo-mechanical grinding of large size quartz glass substrate,” Prec. Eng., Vol. 33, No. 4, pp. 499–504, 2009.

Suwabe, H. and Ishikawa, K., “Nontraditional lapping processes: in Handbook of Lapping and Polishing,” CRC Press, Chapter 4.3, 2007.

Thoe, T. B., Aspinwall, D. K., and Wise, M., “Review on ultrasonic machining,” Int. J. Mach. Tool. Manuf., Vol. 38, No. 4, pp. 239–255, 1998.

Shamoto, E., Suzuki, N., Tsuchiya, E., Hori, Y., Inagaki, H., and Yoshino, K., “Development of 3 DOF ultrasonic vibration tool for elliptical vibration cutting of sculptured surfaces,” Ann. CIRP, Vol. 54, No. 1, pp. 321–324, 2005.

Shamoto, E. and Moriwaki, T., “Study on elliptical vibration cutting,” Ann. CIRP, Vol. 43, No. 1, pp. 35–38, 1994.

Ahn, J.-H., Lim, H.-S., and Son, S.-M., “Improvement of micromachining accuracy by 2-Dimensional vibration cutting,” Proc. ASPE, Vol. 20, pp. 150–153, 1999.

Brinksmeier, E. and Glabe, R., “Elliptical vibration cutting of steel with diamond tools,” Proc. ASPE, Vol. 20, pp. 163–166, 1999.

Li, X. and Zhang, D., “Ultrasonic elliptical vibration transducer driven by single actuator and its application in precision cutting,” J. Mater. Process. Technol., Vol. 180, No. 103, pp. 91–95, 2006.

Timoshenko, S., “Vibration problems in engineering, second edition,” D. Van Nostrand Company, Inc., New York, USA, Chapter 6, 1937.

Wu, Y., Fan, Y., Kato, M., Kuriyagawa, T., Syoji, K., and Tachibana, T., “Development of an ultrasonic elliptic-vibration shoe centerless grinding technique,” J. Mater. Process. Technol., Vol. 155–156, pp. 1780–1787, 2004.

Preston, F. W., “The theory and design of plate glass polishing machines,” J. Soc. Glass Technol., Vol. 11, pp. 214–256, 1927.

Kasai, T. and Yasunaga, N., “Precision grinding for high additional value,” Nikkan Kogyo Shimbun, Ltd., Tokyo, Japan, Chapter 1.1, 2010. (in Japanese)

Suratwala, T. I., Feit, M. D., and Steele, W. A., “Toward deterministic material removal and surface figure during fused silica pad polishing,” J. Amer. Ceram. Soc., Vol. 93, No. 5, pp. 1326–1340, 2010.

Rajendran, A., Takahashi, Y., Koyama, M., Kubo, M., and Miyamoto, A., “Tight-binding quantum chemical molecular dynamics simulation of mechano-chemical reactions during chemical-mechanical polishing process of SiO2 surface by CeO2 particle,” Appl. Surf. Sci., Vol. 244, No. 1–4, pp. 34–38, 2005.

Cook, L. M., “Chemical processes in glass polishing,” J. Non-Crystal. Solids, Vol. 120, No. 1–3, pp. 152–171, 1990.

Hoshino, T., Kurata, Y., Terasaki, Y., and Susa, K., “Mechanism of polishing of SiO2 films by CeO2 particles,” J. Non-Crystal. Solids, Vol. 283, No. 103, pp. 129–136, 2001.

Yu, Z., Hu, X., and Rajurkar, K. P., “Influence of debris accumulation on material removal and surface roughness in micro ultrasonic machining of silicon,” Ann. CIRP, Vol. 55, No. 1, pp. 201–204, 2006.

Author information

Authors and Affiliations

Corresponding author

Additional information

An erratum to this article is available at http://dx.doi.org/10.1007/s12541-014-0423-9.

Rights and permissions

About this article

Cite this article

Li, Y., Wu, Y., Zhou, L. et al. Chemo-mechanical manufacturing of fused silica by combining ultrasonic vibration with fixed-abrasive pellets. Int. J. Precis. Eng. Manuf. 13, 2163–2172 (2012). https://doi.org/10.1007/s12541-012-0287-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-012-0287-9