Abstract

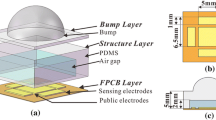

The tactile sensation is the human interact with machines in the form of felt sensations in the hand or other parts of body skin. This paper presents a film type actuator for haptic feedback devices, based on electrostatic actuation of plasticized cellulose acetate stacked membranes actuator, which is fabricated and evaluated for suitability of haptic feedback devices. The stacked membranes actuator shows many promising properties such as high transparency, lightweight, wide range of actuation frequency and high vibration acceleration for instance. The actuator structure shows intense vibration acceleration due to several layers of stacked membranes associated with the intensified electrostatic attraction force between chargeable cellulose acetate membranes. Experiment for measuring vibrational acceleration was conducted over a wide frequency range and actuation voltage to prove actuator’s great potential application as tactile actuator of haptic feedback devices. In addition, the operating principle, fabrication method and performance measurements are explained in details.

Similar content being viewed by others

References

Hamam, A., Eid, M., and El-Saddik, A., “Effect of Kinesthetic and Tactile Haptic Feedback on the Quality of Experience of Edutainment Applications,” Multimedia Tools and Applications, vol. 67, no. 2, pp. 455–472, 2013.

Fritschi, M., Ernst, M. O., and Buss, M., “Integration of Kinesthetic and Tactile Display-A Modular Design Concept,” Proc. of the Euro Haptics International Conference, pp. 607–612, 2006.

Kyung, K. U., Lee, J. Y., and Park, J. S., “Comparison of Force, Tactile and Vibrotactile Feedback for Texture Representation using a Combined Haptic Feedback Interface,” in: Haptic and Audio Interaction Design, Oakley, I. and Brewster, S., (Eds.), Springer Berlin Heidelberg, pp. 34–43, 2007.

Streque, J., Talbi, A., Pernod, P., and Preobrazhensky, V., “New Magnetic Microactuator Design based on PDMS Elastomer and MEMS Technologies for Tactile Display,” IEEE Transactions on Haptics, vol. 3, no. 2, pp. 88–97, 2010.

Panait, L., Akkary, E., Bell, R. L., Roberts, K. E., Dudrick, S. J., et al., “The Role of Haptic Feedback in Laparoscopic Simulation Training,” Journal of Surgical Research, vol. 156, no. 2, pp. 312–316, 2009.

Basdogan, C., De, S., Kim, J., Muniyandi, M., Kim, H., et al., “Haptics in Minimally Invasive Surgical Simulation and Training,” IEEE Computer Graphics and Applications, vol. 24, no. 2, pp. 56–64, 2004.

Turolla, A., Daud-Albasini, O. A., Oboe, R., Agostini, M., Tonin, P., et al., “Haptic-based Neurorehabilitation in Poststroke Patients: A Feasibility Prospective Multicentre Trial for Robotics Hand Rehabilitation,” Computational and Mathematical Methods in Medicine, Vol. 2013, Paper No. 895492, 2013.

Morelli, T. and Folmer, E., “Real-Time Sensory Substitution to Enable Players who are Blind to Play Video Games using Whole Body Gestures,” Entertainment Computing, vol. 5, no. 1, pp. 83–90, 2014.

Kim, Y., Oakley, I., and Ryu, J., “Combining Point Force Haptic and Pneumatic Tactile Displays,” Proc. of the Euro Haptics International Conference, pp. 306–316. 2006.

Sato, K., Kajimoto, H., Kawakami, N., and Tachi, S., “Electrotactile Display for Integration with Kinesthetic Display,” Proc. of 16th IEEE International Symposium on Robot and Human interactive Communication. pp. 3–8, 2007.

Ryu, S., Koo, J. H., Yang, T. H., Pyo, D., Kyung, K. U., et al., “Design, Simulation, and Testing of a Magnetorheological Fluidbased Haptic Actuator for Mobile Applications,” Journal of Intelligent Material Systems and Structures, Document ID: 1045389X14536009, 2014.

Liu, J., Song, A., and Zhang, H., “Research on Stiffness Display Perception of Virtual Soft Object,” Proc. of International Conference on Information Acquisition, pp. 558–562, 2007.

Lim, S. C., Lee, H. K., and Park, J., “Role of Combined Tactile and Kinesthetic Feedback in Minimally Invasive Surgery: Haptic Feedback in Minimmaly Invasive Surgery,” The International Journal of Medical Robotics and Computer Assisted Surgery, DOI: 10.1002/rcs.1625, 2014.

Srinivasan, M. A. and Basdogan, C., “Haptics in Virtual Environments: Taxonomy, Research Status, and Challenges,” Computers & Graphics, vol. 21, no. 4, pp. 393–404, 1997.

Purves, D., Augustine, G. J., Fitzpatrickm D., Hall W. C., Lamantia A. S., et al., “Neuroscience,” Sinauer Associates Inc, p. 192, 2004.

Immersion Corporation, “Haptic Effect Generation with an Eccentric Rotating Mass Actuator,” US Patent, No. 20100116562 A1, 2008.

Kweon, S. D., Park, I. O., Son, Y. H., Choi, J., and Oh, H. Y., “Linear Vibration Motor using Resonance Frequency,” US Patent, No. 20050184601 A1, 2005.

Summers, I. R. and Chanter, C. M., “A Broadband Tactile Array on the Fingertip,” The Journal of the Acoustical Society of America, vol. 112, no. 5, pp. 2118–2186, 2002.

Elspass, W. J. and Kunz, A. M., “Portable Haptic Interface with Active Functional Design,” Proc. of SPIE Smart Structures and Materials, vol. 3668, pp. 926–932, 1999.

Velazquez, R., Pissaloux, E., Szewczyk, J., and Hafez, M., “Miniature Shape Memory Alloy Actuator for Tactile Binary Information Display,” Proc. of the 2005 IEEE International Conference on Robotics and Automation, pp. 1344–1349, 2005.

Klein, D., Freimuth, H., Monkman, G. J., Egersdörfer, S., Meier, A., et al., “Electrorheological Tactel Elements,” Mechatronics, vol. 15, no. 7, pp. 883–897, 2005.

Liu, Y., Davidson, R. I., Taylor, P. M., Ngu, J. D., and Zarraga, J. M. C., “Single Cell Magnetorheological Fluid Based Tactile Display,” Displays, vol. 26, no. 1, pp. 29–35, 2005.

Matysek, M., Lotz, P., Winterstein, T., and Schlaak, H. F., “Dielectric Elastomer Actuators for Tactile Displays,” Proc. of Third Joint Eurohaptics Conference and Symposium on Haptic Interfaces for Virtual Environment and Teleoperator Systems, pp. 290–295, 2009.

Mohiuddin, M., Sadasivuni, K. K., Mun, S., and Kim, J., “Flexible Cellulose Acetate/Graphene Blueprints for Vibrotactile Actuator,” RSC Advances, vol. 5, no. 43, pp. 34432–34438, 2015.

Kim, U., Kang, J., Lee, C., Kwon, H. Y., Hwang, S., et al., “A Transparent and Stretchable Graphene-based Actuator for Tactile Display,” Nanotechnology, vol. 24, no. 14, Paper No. 145501, 2013.

Ma, M., Guo, L., Anderson, D. G., and Langer, R., “Bio-Inspired Polymer Composite Actuator and Generator Driven by Water Gradients,” Science, vol. 339, no. 6116, pp. 186–189, 2013.

Winter, C., Markovic, M., and Perriard, Y., “Empirical Modeling of a Squeeze Film Haptic Actuator,” IEEE Transactions on Industry Applications, vol. 50, no. 3, pp. 1809–1816, 2014.

Akther, A., Mohiuddin, M., Min, S. K., Kim, S. Y., and Kim, J., “Simulation and Experimental Verification of Flexible Cellulose Acetate Haptic Array Actuator,” Proc. of SPIE Nanosensors, Biosensors, and Info-Tech Sensors and Systems, Vol. 9434, Paper No. 943418, 2015.

Kim, J., Yun, S., and Ounaies, Z., “Discovery of Cellulose as a Smart Material,” Macromolecules, vol. 39, no. 12, pp. 4202–4206, 2006.

Yun, G. Y., Kim, J., Kim, J. H., and Kim, S. Y., “Fabrication and Testing of Cellulose EAPap Actuators for Haptic Application,” Sensors and Actuators A: Physical, vol. 164, no. 1, pp. 68–73, 2010.

Mohiuddin, M., Kim, H. C., Kim, S. Y., and Kim, J., “Transparent and Flexible Haptic Array Actuator Made with Cellulose Acetate for Tactile Sensation,” Proc. of SPIE Nanosensors, Biosensors, and Info-Tech Sensors and Systems, Paper No. 906017, 2014.

Kim, S. Y., Kim, J., and Kim, K. B., “Investigation of Size Effect on Film Type Haptic Actuator Made with Cellulose Acetate,” Smart Materials and Structures, vol. 23, no. 4, Paper No. 045016, 2014.

Edgar, K. J., Buchanan, C. M., Debenham, J. S., Rundquist, P. A., Seiler, B. D., et al., “Advances in Cellulose Ester Performance and Application,” Progress in Polymer Science, vol. 26, no. 9, pp. 1605–1688, 2001.

Mohamad, D., Hamzah, W. S. W., Daud, W. R. W., Rajion, Z. A., Bakar, W. Z. W., et al., “Fabrication of Cellulose Acetate Film from Oil Palm Empty Fruit Bunch (OP-EFB) and Cytotoxicity Evaluation,” Pertanika Journal of Science & Technology, vol. 20, no. 1, pp. 189–207, 2012.

Mohanty, A. K., Wibowo, A., Misra, M., and Drzal, L. T., “Development of Renewable Resource-based Cellulose Acetate Bioplastic: Effect of Process Engineering on the Performance of Cellulosic Plastics,” Polymer Engineering & Science, vol. 43, no. 5, pp. 1151–1161, 2003.

Farcich, N. J., Salonen, J., and Asbeck, P. M., “Single-Length Method Used to Determine the Dielectric Constant of Polydimethylsiloxane,” IEEE Transactions on Microwave Theory and Techniques, vol. 56, no. 12, pp. 2963–2971, 2008.

Yun, S., Yun, G. Y., Kim, K. B., Kang, B. W., Kim, J., et al., “Film-Type Haptic Actuator Made with Cellulose Acetate Layers,” Journal of Intelligent Material Systems and Structures, vol. 25, no. 11, pp. 1289–1294, 2014.

Mazzone, A., Zhang, R., and Kunz, A., “Novel Actuators for Haptic Displays based on Electroactive Polymers,” Proceedings of the ACM Symposium on Virtual Reality Software and Technology, pp. 196–204, 2003.

Peizo Electric Technology, “Medical/Bio, Bio Trace Module (MALDI System),” http://www.piezo-tech.com/index.php?hCode=APPLICATION_03_02 (Accssed 1 JUN 2015)

Texas Instrument, “Haptics Solutions for ERM and LRA Actuators,” http://www.ti.com/lit/ml/sszb151/sszb151.pdf (Accessed 18 MAY 2015)

Yun, G. Y., Kim, S. Y., Jang, S. D., Kim, D. G., and Kim, J., “Haptic Device Development based on Electro Static Force of Cellulose Electro Active Paper,” Proc. of SPIE Electroactive Polymer Actuators and Devices, Vol. 7976, Paper No. 797617, 2011.

Hatzfeld, C., Kern, T. A., Stöhr, I., and Werthschützky, R., “Development of a Highly Dynamic Force Source,” Procedia Chemistry, vol. 1, no. 1, pp. 1231–1234, 2009.

Johansson, R. S. and Vallbo, A. B., “Tactile Sensibility in the Human Hand: Relative and Absolute Densities of Four Types of Mechanoreceptive Units in Glabrous Skin,” The Journal of Physiology, vol. 286, no. 1, pp. 283–300, 1979.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mohiuddin, M., Ko, HU., Kim, HC. et al. Transparent and flexible haptic actuator based on cellulose acetate stacked membranes. Int. J. Precis. Eng. Manuf. 16, 1479–1485 (2015). https://doi.org/10.1007/s12541-015-0196-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-015-0196-9