Abstract

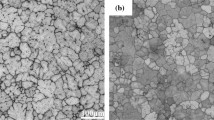

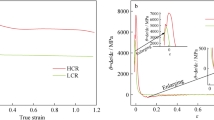

The hot deformation behavior and microstructures of Al-7055 commercial alloy were investigated by axisymmetric hot compression at temperatures ranging from 300°C to 450°C and strain rates from 10−2 to 10 s−1, respectively. Microstructures of deformed 7055 alloy were investigated by transmission electron microscopy (TEM). The dependence of peak stress on deformation temperature and strain rate can be expressed by the hyperbolic-sine type equation. The hot deformation activation energy of the alloy is 146 kJ/mol. Moreover, the flow stress curves predicted by the modified constitutive equations are reasonably consistent with the experimental results, which confirms that the proposed deformation constitutive equations can provide evidence for the selection of hot forming parameters. TEM results indicate that dynamic recovery is the main softening mechanism during hot deformation.

Similar content being viewed by others

References

R. Kaibyshev, T. Sakai, F. Musin, et al., Superplastic behavior of a 7055 aluminum alloy, Scripta Mater., 45(2001), No.12, p.1373.

C. Mondal, A.K. Mukhopadhyay, T. Raghu, and V.K. Varma, Tensile properties of peak aged 7055 aluminum alloy extrusions, Mater. Sci. Eng. A, 455(2007), No.3, p.673.

J.Z. Chen, L. Zhen, W.Z. Shao, et al., Through-thickness texture gradient in AA 7055 aluminum alloy, Mater. Lett., 62(2008), No.1, p.88.

M. Dixit, R.S. Mishra, and K.K. Sankaran, Structure-property correlations in Al 7050 and Al 7055 high-strength aluminum alloys, Mater. Sci. Eng. A, 478(2008), No.1–2, p.163.

S.D. Liu, X.M. Zhang, M.A. Chen, et al., Influence of aging on quench sensitivity effect of 7055 aluminum alloy, Mater. Charact., 59(2008), No.1, p.53.

Z.H. Li, B.Q. Xiong, Y.A. Zhang, et al., Ageing behavior of an Al-Zn-Mg-Cu alloy pre-stretched thick plate, J. Univ. Sci. Technol. Beijing, 14(2007), No.3, p.246.

K.H. Chen, H.W. Liu, Z. Zhang, et al., The improvement of constituent dissolution and mechanical properties of 7055 aluminum alloy by stepped heat treatments, J. Mater. Process. Technol., 142(2003), No.1, p.190.

I. Nikulin, R. Kaibyshev, and T. Sakai, Superplasticity in a 7055 aluminum alloy processed by ECAE and subsequent isothermal rolling, Mater. Sci. Eng. A, 407(2005), No.1–2, p.62.

Q. Zhu, M.F. Abbod, J.T. Alamantes-Silva, et al., Hybrid modelling of aluminium magnesium alloys during thermomechanical processing in terms of physically-based, neuro-fuzzy and finite element models, Acta Mater., 51(2003), No.17, p.5051.

Q.J. Chen, Y.L. Kang, H. Yu, et al., Research on microstructural evolution and dynamic recrystallization behavior of JB800 bainitic steel by FEM, J. Univ. Sci. Technol. Beijing, 15(2008), No.3, p.250.

J. Shen, Study on the Plastic Deformation Behavior of 2091 Al-Li Alloy at Elevated Temperatures [Dissertation] (in Chinese), Central South University of Technology, Changsha, 1996, p.22.

F.J. Humphreys and M. Hatherly, Re-crystallization and Related Annealing Phenomena, Pergamon Press, Oxford, 2004, p.416.

J.T. Liu, G.Q. Liu, B.F. Hu, et al., Hot deformation behavior of FGH96 superalloys, J. Univ. Sci. Technol. Beijing, 13(2006), No.4, p.319.

H. Shi, A.J. McLaren, C.M. Sellars, et al., Constitutive equations for high temperature flow stress of aluminum alloys, Mater. Sci. Technol. A, 13(1997), No.3, p.210.

X.H. He, Z.Q. Yu, G.M. Liu, et al., Mathematical modeling for high temperature flow behavior of as-cast Ti-45Al-8.5Nb-(W,B,Y) alloy, Mater. Des., 30(2009), No.1, p.166.

M. Mulyadi, M.A. Rist, L. Edwards, and J.W. Brooks, Parameter optimisation in constitutive equations for hot forging, J. Mater. Process. Technol., 177(2006), No.1–3, p.311.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, Lm., Shen, J., Li, Jp. et al. Deformation behavior and microstructure of an Al-Zn-Mg-Cu-Zr alloy during hot deformation. Int J Miner Metall Mater 17, 46–52 (2010). https://doi.org/10.1007/s12613-010-0108-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-010-0108-z