Abstract

The time-temperature-transformation (TTT) diagrams of F-free mold fluxes was constructed using single hot thermocouple technique (SHTT) and confocal scanning laser microscopy (CSLM) to study the crystallization behavior of F-free mold fluxes. The tendency of crystallization is found to increase whereas the incubation time decreases with increasing basicity. Zirconia addition enhances the crystallization tendency due to its limited solubility in the slag melt and the solid particles acting as nucleation sites. Pseudo-wollastonite is found to precipitate in the slag with low basicity (CS-1 and CS-2), kilchoanite and larnite are formed with further increasing basicity (CS-3), and larnite is finally formed as the basicity beyond unit (CS-4). The crystal morphology changes with varying compositions and isothermal temperatures. The measured growth rate is found to be linear with time under isothermal conditions and decreases with increasing isothermal temperature.

Similar content being viewed by others

References

K.C. Mills, A.B. Fox, Z. Li, and R.P. Thackray, Performance and properties of mould fluxes, Ironmaking Steelmaking, 32(2005), No.1, p.26.

K.C. Mills and A.B. Fox, The role of mould fluxes in continuous casting: so simple yet so complex, ISIJ Int., 43(2003), No.10, p.1479.

R.G. Hill, N.D. Costa, and R.V. Law, Characterization of a mould flux glass, J. Non Cryst. Solids, 351(2005), No.1, p.69.

W.L. Wang and A.W. Cramb, The observation of mold flux crystallization on radiative heat transfer, ISIJ Int., 45(2005), No.12, p.1864.

C.A.M. Pinheiro, I.V. Samarasekera, J.K. Brimacombe, and B.N. Walker, Heat transfer and continuously cast billet quality with mould flux lubrication: Part 1. Mould heat transfer, Ironmaking Steelmaking, 27(2000), No.1, p.37.

K.C. Mills and A.B. Fox, Mould fluxes, High Temp. Mater. Processes, 22(2004), No.2, p.291.

S. Sridhar, K.C. Mills, O.D.C. Afranqe, H.P. Lörz, and R. Carli, Break temperatures of mould fluxes and their relevance to continuous casting, Ironmaking Steelmaking, 27(2000), No.3, p.238.

K.C. Mills, Physical properties of casting powders: Part 1. Scheme to represent chemical compositions of powders, Ironmaking Steelmaking, 15(1988), No.4, p.175.

C. Orrling, Crystallization Phenomena in Slags [Dissertation], Carnegie Mellon University, Pittsburgh, 2000, p.8.

A.I. Zaitsev, A.V. Leites, A.D. Litvina, and B.M. Mogutnov, Invetigation of the mould powder volatiles during continuous casting, Steel Res., 65(1994), No.9, p.368.

M. Persson, S. Sridhar, and S. Seetharaman, Kinetic studies of fluoride evaporation from slags, ISIJ Int., 47(2007), No.12, p.1711.

A.B. Fox, K.C. Mills, D. Lever, et al., Development of fluoride-free fluxes for billet casting, ISIJ Int., 45(2005), No.7, p.1051.

S.Y. Choi, D.H. Lee, D.W. Shin, S.Y. Choi, J.W. Cho, and J.M. Park, Properties of F-free glass system as a mold flux: viscosity, thermal conductivity and crystallization behavior, J. Non Cryst. Solids, 345–346(2004), No.10, p.157.

G.H. Wen, S. Sridhar, P. Tang, X. Qi and Y.Q. Liu, Development of fluoride-free mold powders for peritectic steel slab casting, ISIJ Int., 47(2007), No.8, p.1117.

H. Nakada and K. Nagata, Crystallization of CaO-SiO2-TiO2 slag as a candidate for fluorine free mold flux, ISIJ Int., 46(2006), No.3, p.441.

A. Yamauchi, K. Sorimachi, T. Sakuraya, and T. Fujii, Heat transfer between mold and strand through mold flux film in continuous casting of steel, ISIJ Int., 33(1993), No.1, p.140.

M. Kawamoto, Y. Tsukaguchi, N. Nishida, T. Kanazawa, and S. Hiraki, Improvement of the initial stage of solidification by using mild cooling mold powder, ISIJ Int., 27(1997), No.2, p.134.

M. Susa, K.C. Mills, M.J. Richardson, R. Taylor, and D. Stewart, Thermal properties of slag films taken from continuous casting mould, Ironmaking Steelmaking, 21(1994), No.4, p.279.

M. Susa, F. Li, and K. Nagata., Thermal conductivity, thermal diffusivity, and specific heat of slags containing iron oxides, Ironmaking Steelmaking, 20(1993), No.3, p.201.

R. Taylor and K.C. Mills, Physical properties of casting powders: Part 3. Thermal conductivities of casting powders, Ironmaking Steelmaking, 15(1988), No.4. p.187.

J.W. Cho, T. Emi, H. Shibata, and M. Suzuki, Heat transfer across mold flux film in mold during initial solidification in continuous casting of steel, ISIJ Int., 38(1998), No.8, p.834.

P. Grieveson, S. Bagha, N. Machingawuta, K. Liddel, and K.C. Mills, Physical properties of casting powders: Part 2. Mineralogical constitution of slags formed by powders, Ironmaking Steelmaking, 15(1988), No.4, p.181.

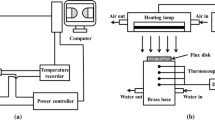

Y. Kashiwaya, C.E. Cicutti, and A.W. Cramb, Investigation of the crystallization of a continuous casting mold slag using the single hot thermocouple technique, ISIJ Int., 38(1998), No.4, p.357.

E.D. Schmidt, E.B. Damn, and S. Sridhar, A study of diffusion- and interface-controlled migration of the austenite/ferrite front during austenitization of a case-hardenable alloy steel, Metall. Mater. Trans. A, 38(2007), No.2, p.244.

H. Yin, T. Emi, and H. Shibata, Morphological instability of δ-ferrite/γ-austenite interphase boundary in low carbon steels, Acta. Mater., 47(1999), No.5, p.1523.

K. C. Mills, Mold Powders for Continuous Casting, Imperial College London Press, London, 2003, p.1.

K.C. Mills, Slag Atlas, Verein Deutscher Eisenhuttenleute (VDEh), Germany, 1995, p.349.

A.B. Fox, M.E. Valdez, J. Gisby, et al., Dissolution of ZrO2, Al2O3 and MgAl2O4 particles in a B2O3 containing commercial fluoride-free mould slag, ISIJ Int., 44(2004), No.5, p.836

C. Orrling, A.W. Cramb, A. Tillander, and Y. Kashiwaya, Observation of the melting and solidification behavior of mold slags, Iron Steelmaker, 27(2000), No.1, p.53.

C.W. Bale, P. Chartrand, S.A. Degterov, et al., Factsage thermochemical software and databases, Calphad, 26(2002), No.2, p.18

K.A. Jackson, Liquid Metals and Solidification, American Society for Metals, Cleveland, 1958, p.174.

P.J. Vergano and D.R. Uhlmann, Crystallisation kinetics of germanium dioxide: the effect of stoichiometry on kinetics, Phys. Chem. Glasses, 11(1970), No.1, p.30.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was financially supported by the National Natural Science Foundation of China (No.50902003) and the Major State Basic Research Development Program of China (No.2007CB613608)

Rights and permissions

About this article

Cite this article

Zhang, Zt., Wen, Gh. & Zhang, Yy. Crystallization behavior of F-free mold fluxes. Int J Miner Metall Mater 18, 150–158 (2011). https://doi.org/10.1007/s12613-011-0415-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-011-0415-z