Abstract

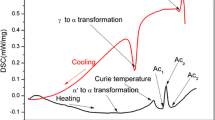

A high speed steel (HSS) was studied for rollers in this work. The steel was quenched at 1150°C and tempered at 520°C. The phase structures of the steel were determined by X-ray diffraction (XRD), and the hardness of specimens was measured. The volume fraction of carbides was counted by Image-Pro Plus software. The typical microstructures were observed by field emission scanning electron microscope (FESEM). Stable and meta-stable carbides were deduced by removing the existing phases one by one in the Fe-C equilibrium calculation. It is found that the precipitated carbides are bulk-like MC, long stripe-like M2C, fishbone-like M6C, and daisy-like M7C3 during the tempering process. The stable carbides are MC and M6C, but the meta-stable ones are M2C, M7C3, and M3C.

Similar content being viewed by others

References

C. Rodenburg and W.M. Rainforth, A quantitative analysis of the influence of carbides size distributions on wear behavior of high-speed steel in dry rolling/sliding contact, Acta Mater., 55(2007), No. 7, p. 2443.

J.W. Park, H.C. Lee, and S. Lee, Composition, microstructure, hardness, and wear properties of high speed steel rolls, Metall. Mater. Trans. A, 30(1999), No. 2, p. 399.

H.G. Fu, Q. Xiao, and J.D. Xing, A study of segregation mechanism in centrifugal cast high speed steel rolls, Mater. Sci. Eng. A, 479(2008), No. 1–2, p 253.

E.S. Lee, W.J. Park, K.H. Baik, and S. Ahn, Different carbide types and their effect on bend properties of a sprayformed high speed steel, Scripta Mater., 39(1998), No. 8, p. 1133.

C.K. Kim, J.I. Park, S. Lee, Y.C. Kim, N.J. Kim, and J.S. Yang, Effects of alloying elements on microstructure, hardness, and fracture toughness of centrifugally cast highspeed steel rolls, Metall. Mater. Trans. A, 36(2005), No. 1, p. 87.

K.C. Hwang, S. Lee, and H.C. Lee, Effects of alloying elements on microstructure and fracture properties of cast high speed steel rolls: Part I. Microstructure analysis, Mater. Sci. Eng., A, 254(1998), No. 1–2, p. 282.

K.C. Hwang, S. Lee, and H.C. Lee, Effects of alloying elements on microstructure and fracture properties of cast high speed steel rolls: Part II. Fracture behavior, Mater. Sci. Eng., A, 254(1998), No. 1–2, p. 296.

S.Z. Wei, J.H. Zhu, L.J. Xu, and R. Long, Effects of carbon on microstructures and properties of high vanadium high-speed steel, Mater. Des., 27(2006), No. 1, p. 58.

S.Z. Wei, J.H. Zhu, and L.J. Xu, Effects of vanadium and carbon on microstructures and abrasive wear resistance of high speed steel, Tribol. Int., 39(2006), No. 7, p. 641.

H.W. Qu, B. Liao, L.G. Liu, D. Li, J. Guo, X.J. Ren, and Q.X. Yang, Precipitation rule of carbides in a new high speed steel for rollers, Calphad, 36(2012), p. 144.

J.L. Liu and Q.Q. Luo, Tempering behaviour of hardened surface of T1 high speed tool steel after laser heating, Mater. Lett., 16(1993), No. 2–3, p. 134.

R. Wang and G.L. Dunlop, The crystallography of secondary carbide precipitation in high speed steel, Acta Metall., 32(1984), No. 10, p. 1591.

S. Yamasaki, Modeling Precipitation of Carbides in Martensitic Steels [Dissertation], Cambridge University, London, 2004, p. 52.

M.M. Serna and J.L. Rossi, MC complex carbide in AISI M2 high-speed steel, Mater. Lett., 63(2009), No. 8, p. 691.

F.M. Yang, X.F. Sun, W. Zhang, Y.P. Kang, H.R. Guan, and Z.Q. Hu, Secondary M6C precipitation in K40S cobaltbase alloy, Mater. Lett., 49(2001), No. 3–4, p. 160.

H.G. Fu and J.D. Xing, Manufacturing Technology of HSS Rollers, Metallurgical Industry Press, Beijing, 2007, p. 73

Y.K. Deng, J.R. Chen, and S.Z. Wang, High Speed Tool Steels, Metallurgical Industry Press, Beijing, 2002, p. 77.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, J., Qu, Hw., Liu, Lg. et al. Study on stable and meta-stable carbides in a high speed steel for rollers during tempering processes. Int J Miner Metall Mater 20, 146–151 (2013). https://doi.org/10.1007/s12613-013-0706-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-013-0706-7