Abstract

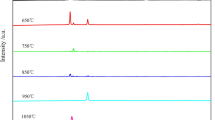

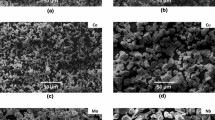

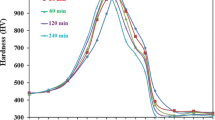

High entropy alloys with the composition of FeCoNiAl0.2Si0.2 were prepared by arc melting and induction melting, denoted by A1 and A2, respectively. The samples prepared by these two techniques have a face-centered cubic (FCC) phase structure and a typical dendrite morphology. The tensile yield strength and maximum strength of A2 samples are about 280 and 632 MPa, respectively. Moreover, the elongation can reach 41.7%. These two alloys prepared by the different methods possess the similar magnetic properties. The saturation magnetization and coercivity can reach 1.151 T and 1400 A/m for Al samples and 1.015 T and 1431 A/m for A2 samples, respectively. Phases in A2 samples do not change, which are heat treated at different temperatures, then quenched in water. Only the sample, which is heat treated at 600°C for 3 h and then furnace cooled, has a new phase precipitated. Besides, the coercivity decreases obviously at this temperature. Cold rolling and the subsequent heat treatment cannot improve the magnetic properties effectively. However, cold rolling plays an important role in improving the strength.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured highentropy alloys with multiple principal elements: novel alloy design concepts and outcomes, Adv. Eng. Mater., 6(2004), No. 5, p. 299.

Y.F. Kao, T.J. Chen, S.K. Chen, and J.W. Yeh, Microstructure and mechanical property of as-cast, -homogenized, and -deformed AlxCoCrFeNi (0 ≤ x ≤ 2) highentropy alloys, J. Alloys Compd., 488(2009), p. 57

Y.J. Zhou, Y. Zhang, T.N. Kim, and G.L. Chen, Microstructure characterizations and strengthening mechanism of multi-principal component AlCoCrFeNiTi0.5 solid solution alloy with excellent mechanical properties, Mater. Lett., 62(2008), p. 2673.

Y.F. Kao, S.K. Chen, T.J. Chen, P.C. Chu, J.W. Yeh, and S.J. Lin, Electrical, magnetic, and Hall properties of AlxCoCrFeNi high-entropy alloys, J. Alloys Compd., 509(2011), p. 1607.

O.N. Senkov, J.M. Scott, S.V. Senkova, D.B. Miracle, and C.F. Woodward, Microstructure and room temperature properties of a high-entropy TaNbHfZrTi alloy, J. Alloys Compd., 509(2011), p. 6043.

Y.P. Wang, B.S. Li, and H.Z. Fu, Solid solution or intermetallics in a high-entropy alloy, Adv. Eng. Mater., 11(2009), p. 641.

Y. Zhang, T.T. Zuo, W.B. Liao, and P.K. Liaw, Processing and properties of high-entropy alloys and micro- and nano-wires, ECS Trans., 41(2012), No. 30, p. 49.

G.J. Wang, B.Q. Xiong, Y.A. Zhang, Z.H. Li, and P.Y. Li, Microstructural characterization of as-cast and homogenized 2D70 aluminum alloy, Int. J. Miner., Metall. Mater., 16(2009), p. 427.

J.W. Yeh, Y.L. Chen, S.J. Lin, and S.K. Chen, Highentropy alloys: a new era of exploitation, Mater. Sci. Forum, 560(2007), p. 1.

J.W. Yeh, Recent progress in high-entropy alloys, Ann. Chim. Sci. Mater., 31(2006), p. 633.

L.M. Martyushev and V.D. Seleznev, Maximum entropy production principle in physics, chemistry and biology, Phys. Rep., 426(2006), p. 1.

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Solid-solution phase formation rules for multi-component alloys, Adv. Eng. Mater.,10(2008), p. 534.

X. Yang and Y. Zhang, Prediction of high-entropy stabilized solid-solution in multi-component alloys, Mater. Chem. Phys., 132(2012), p. 233.

S. Guo, C. Ng, J. Lu, and C.T. Liu, Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys, J. Appl. Phys.,109(2011), art. No. 103505.

Y.L. Chen, C.W. Tsai, C.C. Juan, M.H. Chuang, J.W. Yeh, T.S. Chin, and S.K. Chen, Amorphization of equimolar alloys with HCP elements during mechanical alloying, J. Alloys Compd., 506(2010), p. 210.

V. Dolique, A.L. Thomann, P. Brault, Y. Tessier, and P. Gillon, Complex structure/composition relationship in thin films of AlCoCrCuFeNi high entropy alloy, Mater. Chem. Phys., 117(2009), p. 142.

S. Varalakshmi, M. Kamaraj, and B.S. Murty, Formation and stability of equiatomic and nonequiatomic nanocrystalline CuNiCoZnAlTi high-entropy alloys by mechanical alloying, Metall. Mater. Trans. A, 41(2010), p. 2703.

F.J. Wang, Y. Zhang, G.L. Chen, and H.A. Davies, Cooling rate and size effect on the microstructure and mechanical properties of AlCoCrFeNi high entropy alloy, J. Eng. Mater. Technol., 131(2009), No. 3, part. No. 034501.

C.M. Lin and H.L. Tsai, Evolution of microstructure, hardness, and corrosion properties of high-entropy Al0.5CoCrFeNi alloy, Intermetallics, 19(2011), p. 288.

Y.C. Lin and Y.H. Cho, Elucidating the microstructure and wear behavior for multicomponent alloy clad layers by in situ synthesis, Surf. Coat. Technol., 202(2008), p. 4666.

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, and P.K. Liaw, Refractory high-entropy alloys, Intermetallics, 18(2010), p. 1758.

T.T. Shun and Y.C. Du, Microstructure and tensile behaviors of FCC Al0.3CoCrFeNi high entropy alloy, J. Alloys Compd., 479(2009), No. 1-2, p. 157.

C.W. Tsai, Y.L. Chen, M.H. Tsai, J.W. Yeh, T.T. Shun, and S.K. Chen, Deformation and annealing behaviors of high-entropy alloy Al0.5CoCrCuFeNi, J. Alloys Compd., 486(2009), p. 427.

J.W. Qiao, S.G. Ma, E.W. Huang, C.P. Chuang, P.K. Liaw, and Y. Zhang, Microstructural characteristics and mechanical behaviors of AlCoCrFeNi high-entropy alloys at ambient and cryogenic temperatures, Mater. Sci. Forum, 688(2011), p. 419.

Y. Zhang, T.T. Zuo, Y.Q. Cheng, and P.K. Liaw, Highentropy alloys with high saturation magnetization, electrical resistivity, and malleability, Sci. Rep., 3(2013), p. 1455.

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B, Miracle, Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys, Intermetallics, 19(2011), No. 5, p. 698.

Y. Zhang, X.F. Wang, G.L. Chen, and Y. Qiao, Effect of Ti on the microstructure and properties of CoCrCuFeNiTix high-entropy alloys, Ann. Chim. Sci. Mater., 31(2006), No. 6, p. 699.

X.F. Wang, Y. Zhang, Y. Qiao, and G.L. Chen, Novel microstructure and properties of multicomponent CoCrCuFeNiTix alloys, Intermetallics, 15(2007), p. 357.

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, J. Shi, W.M. Wang, H. Wang, Y.C. Wang, and Q.J. Zhang, Annealing on the structure and properties evolution of the CoCrFeNiCuAl high-entropy alloy, J. Alloys Compd., 502(2010), p. 295.

C. Ng, S. Guo, J.H. Luan, S.Q. Shi, and C.T. Liu, Entropy-driven phase stability and slow diffusion kinetics in an Al0.5CoCrCuFeNi high entropy alloy, Intermetallics, 31(2012), p. 165.

D.L. Shu, J.B. Chen, and Y. Feng, Mechanical Properties of Engineering Materials, China Machine Press, Beijing, 2003, p. 43.

G.F. Sun and W.J. Qiang, Magnetic Materials, Chemical Industry Press, Beijing, 2007, p. 2.

C.J. Qiu, Y.H. Wang, and W. Qu, Physical Properties of Materials, Harbin Institute of Technology Press, Harbin, 2009, p. 120.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zuo, Tt., Ren, Sb., Liaw, P.K. et al. Processing effects on the magnetic and mechanical properties of FeCoNiAl0.2Si0.2 high entropy alloy. Int J Miner Metall Mater 20, 549–555 (2013). https://doi.org/10.1007/s12613-013-0764-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-013-0764-x