Abstract

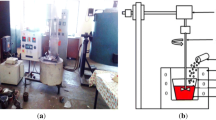

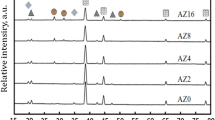

The microstructure and mechanical properties of Al-4.5wt% Cu alloy reinforced with different volume fractions (1.5vol%, 3vol%, and 5vol%) of alumina nanoparticles, fabricated using stir casting method, were investigated. Calculated amounts of alumina nanoparticles (about ϕ50 nm in size) were ball-milled with aluminum powders in a planetary ball mill for 5 h, and then the packets of milled powders were incorporated into molten Al-4.5wt% Cu alloy. Microstructural studies of the nanocomposites reveal a uniform distribution of alumina nanoparticles in the Al-4.5wt% Cu matrix. The results indicate an outstanding improvement in compression strength and hardness due to the effect of nanoparticle addition. The aging behavior of the composite is also evaluated, indicating that the addition of alumina nanoparticles can accelerate the aging process of the alloy, resulting in higher peak hardness values.

Similar content being viewed by others

References

H. Ahamed and V. Senthilkumar, Experimental investigation on newly developed ultrafne-grained aluminium based nano-composites with improved mechanical properties, Mater. Des., 37(2012), p. 182.

X.C. Li, Y. Yang, and D. Weiss, Theoretical and experimental study on ultrasonic dispersion of nanoparticles for strengthening cast aluminum alloy A356, Metall. Sci. Technol., 26(2008), p. 12.

H. Su, W.L. Gao, Z.H. Feng, and Z. Lu, Processing, microstructure and tensile properties of nano-sized Al2O3 particle reinforced aluminum matrix composites, Mater. Des., 36(2012), p. 590.

Y. Yang, J. Lan, and X.C. Li, Study on bulk aluminum matrix nano-composite fabricated by ultrasonic dispersion of nano-sized SiC particles in molten aluminum alloy, Mater. Sci. Eng. A, 380(2004), p. 378.

X.N. Zhang, L. Geng, and G.S. Wang, Fabrication of Albased hybrid composites reinforced with SiC whiskers and SiC nanoparticles by squeeze casting, J. Mater. Process. Technol., 176(2006), p. 146.

S.C. Tjong, Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties, Adv. Eng. Mater., 9(2007), p. 639.

T.A. Chernyshova, L.I. Kobeleva, I.E. Kalashnikov, and L.K. Bolotova, Modification of cast aluminum-matrix composite materials by refractory nanoparticles, Russ. Metall., 1(2009), p. 70.

X.N. Zhang, L. Geng, and G.S. Wang, Microstructure and tensile properties of Al hybrid composites reinforced with SiC whiskers and SiC nanoparticles, Key Eng.Mater., 249(2003), p. 277.

S. Gopalakannan and T. Senthilvelan, EDM of cast Al/SiC metal matrix nanocomposites by applying response surface method, Int. J. Adv. Manuf. Technol., 67(2013), No. 1–4, p. 485.

M. Karbalaei Akbari, H.R. Baharvandi, and O. Mirzaee, Nano-sized aluminum oxide reinforced commercial casting A356 alloy matrix: evaluation of hardness, wear resistance and compressive strength focusing on particle distribution in aluminum matrix, Compos. Part B, 52(2013), p. 262.

E.M. Ruiz-Navas, M.L. Delgado, and B. Trindade, Improvement of the bonding interface of a sintered Al 2014-(Ti5Si3)p composite by the copper coating of the reinforcement, Compos. Part A, 40(2009), p. 1283.

G. Ramu and R. Bauri, Effect of equal channel angular pressing (ECAP) on microstructure and properties of Al-SiCp composites, Mater. Des., 30(2009), p. 3554.

K.M. Shorowordi, T. Laoui, A.S.M.A. Haseeb, J.P. Celis, and L. Froyen, Microstructure and interface characteristics of B4C, SiC and Al2O3 reinforced Al matrix composites: a comparative study, J. Mater. Process. Technol., 142(2003), p. 738.

H. Abdizadeh, H.R. Baharvandi, and K. S. Moghaddam, Comparing the effect of processing temperature on microstructure and mechanical behavior of (ZrSiO4 or TiB2)/aluminum composites, Mater. Sci. Eng. A, 498(2008), p. 53.

J. Hashim, L. Looney, and M.S.J. Hashmi, Metal matrix composites: production by the stir casting method, J. Mater. Process. Technol., 92–93(1999), p. 1.

S.B. Prabu, L. Karunamoorthy, S. Kathiresan, and B. Mohan, Influence of stirring speed and stirring time on distribution of particles in cast metal matrix composite, J. Mater. Process. Technol., 171(2006), p. 268.

M. Kok, Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites, J. Mater. Process. Technol., 161(2005), p. 381.

A. Mazahery, H. Abdizadeh, and H.R. Baharvandi, Development of high-performance A356/nano-Al2O3 composites, Mater. Sci. Eng. A, 518(2009), p. 61.

M.K. Akbari, O. Mirzaee, and H.R. Baharvandi, Fabrication and study on mechanical properties and fracture behavior of nanometric Al2O3 particle-reinforced A356 composites focusing on the parameters of vortex method, Mater. Des., 46(2013), p. 199.

S. Amirkhanlou, M.R. Rezaei, B. Niroumand, and M.R. Toroghinejad, High-strength and highly-uniform composites produced by compocasting and cold rolling processes, Mater. Des., 32(2011), p. 2085.

M. Ghahremanian, B. Niroumand, and M. Panjepour, Production of Al-Si-SiCp cast composites by injection of lowenergy ball-milled Al-SiCp powder into the melt, Met. Mater. Int., 18(2012), p. 149.

S. Amirkhanlou and B. Niroumand, Synthesis and characterization of 356-SiCp composites by stir casting and compocasting methods, Trans. Nonferrous Met. Soc. China, 20(2010), p. s788.

S. Amirkhanlou and B. Niroumand, Development of Al356/SiCp cast composites by injection of SiCp containing composite powders, Mater. Des., 32(2011), p. 1895.

S. Das, S. Das, and K. Das, Ageing behavior of Al-4.5wt% Cu matrix alloy reinforced with Al2O3 and ZrSiO4 particulate varying particle size, J. Mater. Sci., 41(2006), p. 5402.

K. Das and L.K. Narnaware, Synthesis and characterization of Al-4.5% Cu/Al3Ti composites: Microstructure and ageing behaviors, Mater. Sci. Eng. A, 497(2008), p. 25.

J.N. Wei, Z.B. Li, and F.S. Han, Thermal mismatch dis locations in macroscopic graphite particle-reinforced metal matrix composites studied by internal friction, Phys. Status Solidi A, 191(2002), p. 125.

Ashutosh, Study of the Age Hardening Behavior of Al-4.5Cu/ZrSiO 4 Composite in Different Quenching Media [Dissertation], Thapar University, Patiala, 2007, p. 26.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Valibeygloo, N., Azari Khosroshahi, R. & Taherzadeh Mousavian, R. Microstructural and mechanical properties of Al-4.5wt% Cu reinforced with alumina nanoparticles by stir casting method. Int J Miner Metall Mater 20, 978–985 (2013). https://doi.org/10.1007/s12613-013-0824-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-013-0824-2