Abstract

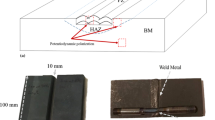

A new procedure was proposed for evaluating the weldability of nickel-base superalloys. The theory is on the basis of two microstructural patterns. In pattern I, the weld microstructure exhibits severe alloying segregation, many low-melting eutectic structures, and low weldability. The weld requires a weaker etchant and a shorter time for etching. In pattern II, the weld microstructure displays less alloying segregation, low quantity of eutectic structures, and high weldability. The weld needs a stronger etchant and a longer time for etching. Five superalloys containing different amounts of Nb and Ti were designed to verify the patterns. After welding operations, the welds were etched by four etchants with different corrosivities. The weldability was determined by TG-DSC measurements. The metallography and weldability results confirmed the theoretic patterns. Finally, the etchant corrosivity and etching time were proposed as new criteria to evaluate the weldability of nickel-base superalloys.

Similar content being viewed by others

References

Properties and Selection: Non-ferrous Alloys and Special-Purpose Material, ASM Handbook, Vol. 2, ASM International, Ohio, 2005, p. 1362.

R.C. Reed, The Superalloys Fundamentals and Applications, Cambridge University Press, Cambridge, 2006, p. 1.

A. Wagner, B.A. Shollock, and M. McLean, Grain structure development in directional solidification of nickel-base superalloys, Mater. Sci. Eng. A, 374(2004), p. 270.

H.S. Whitesell and R.A. Overfelt, Influence of solidification variables on the microstructure, macrosegregation, and porosity of directionally solidified Mar-M247, Mater. Sci. Eng. A, 318 (2001), p. 264.

D. Chatterjee, N. Hazaria, N. Dasa, and R. Mitra, Microstructure and creep behavior of DMS4-type nickel based superalloy single crystals with orientations near 〈001〉 and 〈011〉, Mater. Sci. Eng. A, 528(2010), p. 604.

H.T. Pang, H.B. Dong, R. Beanland, H.J. Stone, C.M.F. Rae, P.A. Midgley, G. Brewster, and N. D’Souza, Microstructure and solidification sequence of the interdendritic region in a third generation single-crystal nickel-base superalloy, Metall. Mater. Trans. A, 40(2009), p. 1660.

F. Zupani T. Bonina, A. Križman, B. Markoli, and S. Spai Microstructural constituents of the Ni-based superalloy GMR 235 in the as-cast condition, Scripta Mater., 46(2002), p. 667.

C.N. Wei, H.Y. Bor, and L. Chang, The effects of carbon content on the microstructure and elevated temperature tensile strength of a nickel-base superalloy, Mater. Sci. Eng. A, 527(2010), p.3741.

J.N. Dupont, J. Lippold, and S. Kiser, Welding Metallurgy and Weldability of Nickel-Base Alloys, Wiely and Sons Inc. Publication, New Jersy, 2009.

H. Naffakh, M. Shamanian, and F. Ashrafizadeh, Influence of artificial aging on microstructure and mechanical properties of dissimilar welds between 310 stainless steel and INCONEL 657, Metall. Mater. Trans. A, 39 (2008), p. 2403.

H. Naffakh, M. Shamanian, and F. Ashrafizadeh, Microstructural evolutions in dissimilar welds between AISI 310 austenitic stainless steel and Inconel 657, J. Mater. Sci., 45(2010), p. 2564.

J.N. Dupont, S.W. Banovic, and A.R. Marder, Microstructural evolution and weldability of dissimilar welds between a super austenitic stainless steel and nickel-based alloys, Weld. J. 86(2003), No. 2, p. 125.

J.N. DuPont, Microstructural development and solidification cracking susceptibility of a stabilized stainless steel, Weld. J., 78(1999), No. 7, p. 253.

J.N. DuPont, C.V. Robino, and A.R. Marder, Modeling solute redistribution and microstructural development in fusion welds of nb-bearing superalloys, Acta Mater., 46(1998), p. 4781.

H.N. Moosavy, M.R. Aboutalebi, and S.H. Seyedein, An analytical algorithm to predict weldability of precipitation-strengthened nickel-base superalloys, J. Mater. Process. Technol., 212(2012), p. 2210.

J.N. DuPont, C.V. Robino, J.R. Michael, M.R. Notis, and A.R. Marder, Solidification of Nb-bearing superalloys: Part I. Reaction sequences, Metall. Mater. Trans. A, 29(1998), p. 2785.

H. Naffakh, M. Shamanian, and F. Ashrafizadeh, Weldability in dissimilar welds between Type 310 austenitic stainless steel and Alloy 657, J. Mater. Sci., 43(2008), p. 5300.

M. Qian and J. C. Lippold, Liquation phenomena in the simulated heat-affected zone of alloy 718 after multiple postweld heat treatment cycles, Weld. J., 82(2003), No. 6, p. 145.

H. Naffakh, M. Shamanian, and F. Ashrafizadeh, Dissimilar welding of AISI 310 austenitic stainless steel to nickelbased alloy Inconel 657, J. Mater. Process. Technol., 209(2009), p. 3628.

M. Qian and J.C. Lippold, The effect of rejuvenation heat treatments on the repair weldability of wrought Alloy 718, Mater. Sci. Eng. A, 340(2003), p. 225.

O.A. Ojo, N.L. Richards, and M.C. Chaturvedi, Contribution of constitutional liquation of gamma prime precipitate to weld HAZ cracking of cast Inconel 738 superalloy, Scripta Mater., 50(2004), p. 641.

Metallography and Microstructures, ASM Handbook, Vol. 9, ASM International, Ohio, 2004, p. 1998.

Corrosion: Fundamentals, Testing, and Protection. ASM Handbook. Vol. 13A, ASM International, Ohio, 2003, p. 18.

M.G. Fontana, Corrosion Engineering, 3rd Ed., McGraw-Hill, New York, 1986, p. 8.

A.T. Egbewande, H.R. Zhang, R.K. Sidhu, and O.A. Ojo, Improvement in laser weldability of INCONEL 738 superalloy through microstructural modification, Metall. Mater. Trans. A, 40(2009), p. 2694.

J.N. DuPont, A combined solubility product/new PHACOMP approach for estimating temperatures of secondary solidification reactions in superalloy weld metals containing Nb and C, Metall. Mater. Trans. A, 29(1998), p. 1449.

Y. Danis. C. Arvieu, E. Lacoste, T. Larrouy, and J.M. Quenisset, An investigation on thermal, metallurgical and mechanical states in weld cracking of Inconel 738LC superalloy, Mater. Des., 31(2010), p.402.

G.V.S. Murthy, G. Sridhar, A. Kumar, and T. Jayakumar, Characterization of intermetallic precipitates in a Nimonic alloy by ultrasonic velocity measurements, Mater. Charact., 60(2009), p. 234.

A. Odabai, N. Ünlü, G. Göller, and M.N. Eruslu, A study on laser beam welding (LBW) technique: effect of heat input on the microstructural evolution of superalloy Inconel 718, Metall. Mater. Trans. A, 41(2010), p. 2357.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moosavy, H.N., Aboutalebi, MR., Seyedein, S.H. et al. New approach for assessing the weldability of precipitation-strengthened nickel-base superalloys. Int J Miner Metall Mater 20, 1183–1191 (2013). https://doi.org/10.1007/s12613-013-0853-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-013-0853-x