Abstract

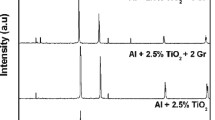

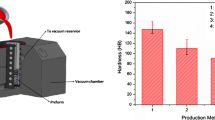

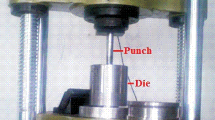

Aluminium-based metal matrix composites were synthesized from Al-TiO2-Gr powder mixtures using the powder metallurgy technique and their forming characteristics were studied during cold upsetting. Green cylindrical compacts of pure Al, Al-5wt%TiO2, Al-5wt%TiO2-2wt%Gr, and Al-5wt%TiO2-4wt%Gr were made using a 400-kN hydraulic press equipped with suitable punch and die and by sintering at (590 ± 10)°C for 3 h. Cold upset forging tests were carried out, the true axial stress (σ z ), the true hoop stress (σ θ ), and the true hydrostatic stress (σ m) were evaluated and, their behavior against the true axial strain (ɛ z ) was also analyzed. It is observed that the addition of 5wt% TiO2 into the Al matrix increases σ z , σ θ , and σ m. The addition of both TiO2 and Gr reinforcements reduces the densification and deformation characteristics of the sintered preforms during cold upsetting. Microstructure analyses of the as-sintered and cold upset forged specimens also were carried out to substantiate the experimental results.

Similar content being viewed by others

References

F. Ji, M.Z. Ma, A.J. Song, W.G. Zhang, H.T. Zong, S.X. Liang, Y. Osamu, and R.P. Liu, Creep behavior of in situ TiCP/2618 aluminum matrix composite, Mater. Sci. Eng. A, 506(2009), No. 1–2, p. 58.

M. Rahimian, N. Parvin, and N. Ehsani, The effect of production parameters on microstructure and wear resistance of powder metallurgy Al-Al2O3 composite, Mater. Des., 32(2011), p. 1031.

S. Sivasankaran, R. Narayanasamy, T. Ramesh, and M. Prabhakar, Analysis of workability behavior of Al-SiC P/M composites using backpropagation neural network model and statistical technique, Comput. Mater. Sci., 47(2009), p. 46.

R. Narayanasamy, T. Ramesh, and K.S. Pandey, An investigation on instantaneous strain hardening behaviour in three dimensions of aluminium-iron composites during cold upsetting, Mater. Sci. Eng. A, 394(2005), p. 149.

R. Narayanasamy, V. Anandakrishnan, and K.S. Pandey, Effect of geometric work-hardening and matrix work-hardening on workability and densification of aluminium-3.5% alumina composite during cold upsetting, Mater. Des., 29(2008), p. 1582.

R. Narayanasamy, T. Ramesh, and M. Prabhakar, Effect of particle size of SiC in aluminium matrix on workability and strain hardening behaviour of P/M composite, Mater. Sci. Eng. A, 504(2009), p. 13.

R. Narayanasamy, T. Ramesh, and K.S. Pandey, Some aspects on strain hardening behaviour in three dimensions of aluminium-iron powder metallurgy composite during cold upsetting, Mater. Des., 27(2006), p. 640.

R. Narayanasamy, T. Ramesh, and K.S. Pandey, Workability studies on cold upsetting of Al-Al2O3 composite material, Mater. Des., 27(2006), p. 566.

M. Rahimian, N. Parvin, and N. Ehsani, Investigation of particle size and amount of alumina on microstructure and mechanical properties of Al matrix composite made by powder metallurgy, Mater. Sci. Eng. A, 527(2010), p. 1031.

A. Mazahery and M.O. Shabani, Study on microstructure and abrasive wear behavior of sintered Al matrix composites, Ceram. Int., 38(2012), p. 4263.

P. Ravindran, K. Manisekar, P. Narayanasamy, N. Selvakumar, and R. Narayanasamy, Application of factorial techniques to study the wear of Al hybrid composites with graphite addition, Mater. Des., 39(2012), p. 42.

M. T. Hayajneh, A.M. Hassan, and A.T. Mayyas, Artificial neural network modeling of the drilling process of self-lubricated aluminum/alumina/graphite hybrid composites synthesized by powder metallurgy technique, J. Alloys Compd., 478(2009), p. 559.

Z. S. Ren, X.J. Hu, S.Y. Li, X.X. Xue, and K.C. Chou, Interdiffusion in the Fe2O3-TiO2 system, Int. J. Miner. Metall. Mater., 20(2013), No. 3, p. 273.

M. L.T. Guo and C.Y.A. Tsao, Tribological behavior of self-lubricating aluminium/SiC/graphite hybrid composites synthesized by the semi-solid powder-densification method, Compos. Sci. Technol., 60(2000), p. 65.

T. Ramesh, M. Prabhakar, and R. Narayanasamy, Workability studies on Al-5%SiC powder metallurgy composite during cold upsetting, Int. J. Adv. Manuf. Technol., 44(2009), p. 389.

C. Suryanarayana, Mechanical alloying and milling, Prog. Mater. Sci., 46(2001), p. 1.

S. Sivasankaran, K. Sivaprasad, R. Narayanasamy, and V.K. Iyer, An investigation on flowability and compressibility of AA 6061100−x -x wt.% TiO2 micro and nanocomposite powder prepared by blending and mechanical alloying, Powder Technol., 201(2010), p. 70.

R. Narayanasamy, V. Anandakrishnan, and K.S. Pandey, Effect of carbon content on instantaneous strain-hardening behaviour of powder metallurgy steels, Mater. Sci. Eng. A, 497(2008), p. 505.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ravichandran, M., Naveen Sait, A. & Anandakrishnan, V. Synthesis and forming behavior of aluminium-based hybrid powder metallurgic composites. Int J Miner Metall Mater 21, 181–189 (2014). https://doi.org/10.1007/s12613-014-0883-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-0883-z