Abstract

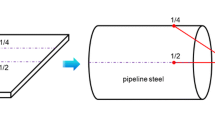

Subsurface macro-inclusions and hooks are detrimental to the surface quality of deep-drawing steel sheets. However, little is known about the relationship between macro-inclusions and hooks. Thus, in this work, two ultralow carbon (ULC) steel slabs and two low carbon (LC) aluminum-killed steel slabs were sampled to study the relationship between hooks and subsurface macro-inclusions, which were detected on the cross-sections of steel samples with an area of 56058 mm2 using an automated scanning electron microscopy/energy-dispersive X-ray spectroscopy system. Results show that subsurface inclusions larger than 200 μm were almost entrapped by hook structures, whereas the location of other inclusions smaller than 200 μm had no obvious dependence on the location of solidified hooks. Furthermore, the number density (ND) of subsurface inclusions larger than 200 μm decreased from 0.02 to 0 cm−2 in ULC steel as the mean hook depth decreased from 1.57 to 1.01 mm. Similar trends were also observed in LC steel. In addition, the detected inclusions larger than 200 μm were concentrated in the region near the slab center (3/8 width-5/8 width), where hook depths were also larger than those at any other locations. Therefore, minimizing the hook depth is an effective way to reduce inclusion-induced sliver defects in deep-drawing steels.

Similar content being viewed by others

References

S.H. Chen, M. Jiang, X.F. He, and X.H. Wang, Top slag refining for inclusion composition transform control in tire cord steel, Int. J. Miner. Metall. Mater., 19(2012), No. 6, p. 490.

C.B. Shi, X.C. Chen, and H.J. Guo, Characteristics of inclusions in high-Al steel during electroslag remelting process, Int. J. Miner. Metall. Mater., 19(2012), No. 4, p. 295.

W. Yang, X.H. Wang, L.F. Zhang, Q.L. Shan, and X.F. Liu, Cleanliness of low carbon aluminum-killed steels during secondary refining processes, Steel Res. Int., 84(2013), No. 5, p. 473.

W. Yang, X.H. Wang, L.F. Zhang, and W.J. Wang, Characteristics of alumina-based inclusions in low carbon Al-killed steel under no-stirring condition, Steel Res. Int., 84(2013), No. 9, p. 878.

Q.Y. Zhang, L.T. Wang, and X.H. Wang, Influence of casting speed variation during unsteady continuous casting on non-metallic inclusions in IF steel slabs, ISIJ Int., 46(2006), No. 10, p. 1421.

M. Wang, Y.P. Bao, H. Cui, W.S. Wu, H.J. Wu, B. Chen, C.X. Ji, and G.S. Zhu, Surface cleanliness evaluation in Ti stabilised ultralow carbon (Ti-IF) steel, Ironmaking Steelmaking, 38(2011), No. 5, p. 386.

G.G. Lee, B.G. Thomas, S.H. Kim, H.J. Shin, S.K. Baek, C.H. Choi, D.S. Kim, and S.J. Yu, Microstructure near corners of continuous-cast steel slabs showing three-dimensional frozen meniscus and hooks, Acta Mater., 55(2007), No. 20, p. 6705.

J. Sengupta, B.G. Thomas, H.J. Shin, G.G. Lee, and S.H. Kim, A new mechanism of hook formation during continuous casting of ultra-low-carbon steel slabs, Metall. Mater. Trans. A, 37(2006), No. 5, p. 1597.

H. Yamamura, Y. Mizukami, and K. Misawa, Formation of a solidified hook-like structure at the subsurface in ultra low carbon steel, ISIJ Int., 36(1996), Suppl., p. S223.

K.D. Schmidt, F. Friedel, K.P. Imlau, W. Jager, and K.T. Muller, Consequent improvement of surface quality by systematic analysis of slabs, Steel Res. Int., 74(2003), No. 11–12, p. 659.

S. Itoyama, H. Yamanaka, S. Tanaka, T. Yunde, and T. Kuroki, Prediction and prevention system for sticking type breakout in continuous casting, [in] The 71st Steelmaking Conference, Toronto, 1988, p. 97.

K. Schwerdtfeger and H. Sha, Depth of oscillation marks forming in continuous casting of steel, Metall. Mater. Trans. B, 31(2000), No. 4, p. 813.

J.P. Birat, M. Larecq, J.Y. Lamant, and J. Petegnief, The continuous casting mold: a basic tool for surface quality and strand productivity, [in] The 74th Steelmaking Conference, Warrendale, 1991, p. 3.

J. Sengupta, B.G. Thomas, H.J. Shin, and S.H. Kim, Mechanism of hook formation in ultralow-carbon steel based on microscopy analysis and thermal-stress modeling, Iron Steel Technol., 4(2007), No. 7, p. 13.

R. Bommaraju, T. Jackson, J. Lucas, G. Skoczylas, and B. Clark, Design, development and application of mold powder to reduce slivers, [in]_The 75th Steelmaking Conference, Toronto, 1992, p. 23.

G.G. Lee, H.J. Shin, S.H. Kim, S.K. Kim, W.Y. Choi, and B.G. Thomas, Prediction and control of subsurface hooks in continuous cast ultra-low-carbon steel slabs, Ironmaking Steelmaking, 36(2009), No. 1, p. 39.

T. Wada, M. Suzuki, and T. Mori, High speed casting of 3 meters/minute on the NKK Fukuyama Works’ No. 5 slab caster, Iron Steelmaker, 14(1987), No. 9, p. 31.

T. Toh, E. Takeuchi, M. Hojo, H. Kawai, and S. Matsumura, Electromagnetic control of initial solidification in continuous casting of steel by low frequency alternating magnetic field, ISIJ Int., 37(1997), No. 11, p. 1112.

S.G. Kollberg, H.R. Hackl, and P.J. Hanley, Improving quality of flat rolled products using electromagnetic brake (EMBR) in continuous casting, Iron Steel Eng, 73(1996), No. 7, p. 24.

Y. Awajiya, Y. Kubota, and S. Takeuchi, Inclusion entrapment location in solidified shell of ultra low carbon steel slab, [in]_Association for Iron & Steel Technology 2005 Conference Proceedings, Charlotte, North Carolina, 2005, p. 65.

S. Basu, S.K. Choudhary, and N.U. Girase, Nozzle clogging behaviour of Ti-bearing Al-killed ultra low carbon steel, ISIJ Int., 44(2004), No. 10, p. 1653.

A. Kumar, S.K. Choudhary, and S.K. Ajmani, Distribution of macroinclusions across slab thickness, ISIJ Int., 52(2012), No. 12, p. 2305.

Y. Miki and S. Takeuchi, Internal defects of continuous casting slabs caused by asymmetric unbalanced steel flow in mold, ISIJ Int., 43(2003), No. 10, p. 1548.

L.F. Zhang, B. Rietow, B.G. Thomas, and K. Eakin, Large inclusions in plain-carbon steel ingots cast by bottom teeming, ISIJ Int., 46(2006), No. 5, p. 670.

W.H. Emling, T.A. Waugaman, S.L. Feldbauer, and A.W. Cramb, Subsurface mold slag entrainment in ultra low carbon steels, [in] The 77th Steelmaking Conference, Chicago, 1994, p. 371.

H. Shibata, H. Yin, S. Yoshinaga, T. Emi, and M. Suzuki, In-situ observation of engulfment and pushing of nonmetallic inclusions in steel melt by advancing melt/solid interface, ISIJ Int., 38(1998), No. 2, p. 149.

L.F. Zhang and B.G. Thomas, State of the art in evaluation and control of steel cleanliness, ISIJ Int., 43(2003), No. 3, p. 271.

H.T. Tsai, W.J. Sammon, and D.E. Hazelton, Characterization and countermeasures for sliver defects in cold rolled products, [in] The 73rd Steelmaking Conference, Detroit, 1990, p. 49.

A.W. Cramb, High purity, low residual, and clean steels, [in]_C.L. Briant ed., Impurities in Engineered Materials: Impact, Reliability and Control, Marcel Dekker Inc., New York, 1999, p. 50.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, Xx., Li, Lp., Wang, Xh. et al. Subsurface macro-inclusions and solidified hook character in aluminum-killed deep-drawing steel slabs. Int J Miner Metall Mater 21, 531–543 (2014). https://doi.org/10.1007/s12613-014-0939-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-0939-0