Abstract

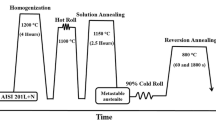

This article reports the effects of Sn on the inclusions as well as the mechanical properties and hot workability of ferritic stainless steel. Precipitation phases and inclusions in Sn-bearing ferritic stainless steel were observed, and the relationship between the workability and the microstructure of the steel was established. Energy-dispersive X-ray spectroscopic analysis of the steel reveals that an almost pure Sn phase forms and MnS-Sn compound inclusions appear in the steel with a higher Sn content. Little Sn segregation was observed in grain boundaries and in the areas around sulfide inclusions; however, the presence of Sn does not adversely affect the workability of the steel containing 0.4wt% Sn. When the Sn content is 0.1wt%–0.4wt%, Sn improves the tensile strength and the plastic strain ratio and also improves the plasticity with increasing temperature. A mechanism of improving the workability of ferritic stainless steel induced by Sn addition was discussed: the presence of Sn lowers the defect concentration in the ultra-pure ferritic lattice and the good distribution of tin in the lattice overcomes the problem of hot brittleness that occurs in low-carbon steel as a result of Sn segregation.

Similar content being viewed by others

References

T. Oshima, Y. Habara, and K. Kuroda, Efforts to save nickel in austenitic stainless steels, ISIJ Int., 47(2007), No. 3, p. 359.

C.C. Silva, J.P. Farias, H.C. Miranda, R.F. Guimaraes, J.W. Menezes, and M.A. Neto, Microstructural characterization of the HAZ in AISI 444 ferritic stainless steel welds, Mater. Charact., 59(2008), No. 5, p. 528.

A. Pardo, M.C. Merino, M. Carboneras, A.E. Coy, and R. Arrabal, Pitting corrosion behaviour of austenitic stainless steels with Cu and Sn additions, Corros. Sci., 49(2007), p. 510.

A. Pardo, M.C. Merino, M. Carboneras, F. Viejo, R. Arrabal, and J. Munoz, Influence of Cu and Sn content in the corrosion of AISI 304 and 316 stainless steels in H2SO4, Corros. Sci., 48(2006), p. 1075.

H.B. Li, Z.H. Jiang, H. Feng, H.C. Zhu, B.H. Sun, and Z. Li, Corrosion behavior of ferritic stainless steel with 15wt% chromium for the automobile exhaust system, Int. J. Miner, Metall. Mater., 20(2013), No. 9, p. 850.

R.S. Wang, Effect of deleterious element Sn and Pb content on hot workability of stainless steel, Spec Steel, 30(2000), No. 1, p. 10.

M.S. Geng, X.H. Wang, J.M. Zhang, W.J. Wang, and J.G. Xiao, Effect of Cu, As, and Sn on the low ductility region III of low alloy steel continuous casting slabs, J. Univ. Sci. Technol. Beijing, 31(2009), No. 4, p. 433.

L.Z. Zhang, X.Y. Liu, X.H. Wang, Y.Y. Zhou, and Z.X. Yin, Hot ductility of high purity 16MnR low alloy steel CC slab, Iron Steel, 36(2001), No. 12, p. 51.

M. Haj, H. Mansouri, R. Vafaei, G.R. Ebrahimi, and A. Kanani, Hot compression deformation behavior of AISI 321 austenitic stainless steel, Int. J. Miner, Metall. Mater., 20(2013), No. 6, p. 529.

X.K. Zhu and Y.J. Chao, Numerical simulation of transient temperature and residual stresses in friction stir welding of 304L stainless steel, J. Mater. Process. Technol., 146(2004), No. 2, p. 263.

N.D. Nam, J.K. Min, W.J. Young, and J.G. Kim, Effect of tin on the corrosion behavior of low-alloy steel in an acid chloride solution, Corros. Sci., 52(2010), No. 1, p. 14.

G.J. Wang, S.S Zhu, Y. Zhu, and A.T. Xu, 38CrSi corrosive fatigue crack propagation model by various polarization potentials, Int. J. Electrochem. Sci., 8(2013), No.4, p. 5539.

T.D. Xu and B.Y. Chen, Kinetics of non-equilibrium grain boundary segregation, Prog. Mater. Sci., 49(2004), No. 2, p. 109.

Z.W. Xu, C.C. Jia, C.J. Kuang, and X.H. Qu, Fabrication and sintering behavior of high-nitrogen nickel-free stainless steels by metal injection molding, Int. J. Miner, Metall. Mater., 17(2010), No. 4, p. 423.

W.T. Nachtrab and Y.T. Chou, The effect of Sn, Al, and N on the hot ductility of a carbon-manganese steel between 700°C and 1200°C, Metall. Mater. Trans. A, 19(1988), No. 5, p. 1305.

J.J. Shim and J.G. Kim, Copper corrosion in potable water distribution systems: influence of copper products on the corrosion behavior, Mater. Lett. 58(2004), No. 14, p. 2002.

R. Balasubramaniam, On the corrosion resistance of the Delhi iron pillar, Corros Sci, 42(2000), No.12, p. 2103.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Han, Jp., Jiang, Zh. et al. Effect of tin addition on the microstructure and properties of ferritic stainless steel. Int J Miner Metall Mater 22, 37–44 (2015). https://doi.org/10.1007/s12613-015-1041-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-015-1041-y