Abstract

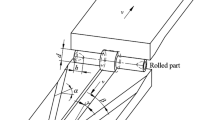

In the shaping process of cross wedge rolling (CWR), metal undergoes a complex microstructural evolution, which affects the quality and mechanical properties of the product. Through secondary development of the DEFORM-3D software, we developed a rigid plastic finite element model for a CWR-processed rear axle tube, coupled with thermomechanical and microstructural aspects of workpieces. Using the developed model, we investigated the microstructural evolution of the CWR process. Also, the influence of numerous parameters, including the initial temperature of workpieces, the roll speed, the forming angle, and the spreading angle, on the grain size and the grain-size uniformity of the rolled workpieces was analyzed. The numerical simulation was verified through rolling and metallographic experiments. Good agreement was obtained between the calculated and experimental results, which demonstrated the reliability of the model constructed in this work.

Similar content being viewed by others

References

Z.K. Wang, The numeric simulation and study of experiments in combined extrusion forming of vehicle hub axles, J. Plast. Eng., 15(2008), No. 6, p. 67.

Z.H. Hu, K.S. Zhang, B.Y. Wang, X.D. Shu, and C.P. Yang, The Forming Technology and Simulation of Shafts with Cross Wedge Rolling, Metallurgical Industry Press, Beijing, 2004, p. 4.

J. Bartnicki and Z. Pater, Numerical simulation of three-rolls cross-wedge rolling of hollowed shaft, J. Mater. Process. Technol., 164-165(2005), p. 1154.

J. Bartnicki and Z. Pater, The aspects of stability in cross-wedge rolling processes of hollowed shafts, J. Mater. Process. Technol., 155-156(2004), p. 1867.

S. Urankar, M. Lovell, C. Morrow, Q. Li, and K. Kawada, Establishment of failure conditions for the cross-wedge rolling of hollow shafts, J. Mater. Process. Technol., 177(2006), No. 1-3, p. 545.

C.P. Yang and Z.H. Hu, Research on the ovality of hollow shafts in cross wedge rolling with mandrel, Int. J. Adv. Manuf. Technol., 83(2016), No. 1, p. 67.

C.P. Yang, K.S. Zhang, and Z.H. Hu, Numerical simulation study on the cause of ellipse generation in two-roll cross wedge rolling the hollow parts with uniform inner diameter, J. Univ. Sci. Technol. Beijing, 34(2012), No. 12, p. 1426.

C.P. Yang, K.S. Zhang, and Z.H. Hu, Simulation analysis of cross wedge rolling hollow parts with mandrel, Adv. Mater. Res., 538-541(2012), p. 542.

K.S. Zhang, J.P. Liu, B.Y. Wang, and Z.H. Hu, Analysis on stable rolling condition of hollow workpiece rolled by cross wedge rolling, J. Univ. Sci. Technol. Beijing, 23(2001), No. 2, p. 155.

F.Q. Ying and B.S. Pan, Analysis on temperature distribution in cross wedge rolling process with finite element method, J. Mater. Process. Technol., 187-188(2007), p. 392.

H.C. Ji, J.P. Liu, B.Y. Wang, Z.H. Zheng, J.H. Huang, and Z.H. Hu, Cross-wedge rolling of a 4Cr9Si2 hollow valve: explorative experiment and finite element simulation, Int. J. Adv. Manuf. Technol., 77(2015), No. 1, p. 15.

M.T. Wang, X.T. Li, F.S. Du, and Y.Z. Zheng, A coupled thermal-mechanical and microstructural simulation of the cross wedge rolling process and experimental verification, Mater. Sci. Eng. A, 391(2005), No. 1-2, p. 305.

M.T. Wang, X.T. Li, F.S. Du, and Y.Z. Zheng, Hot deformation of austenite and prediction of microstructural evolution of cross-wedge rolling, Mater. Sci. Eng. A, 379(2004), No. 1-2, p. 133.

X.T. Li, M.T. Wang, and F.S. Du, The coupling thermal–mechanical and microstructural model for the FEM simulation of cross wedge rolling, J. Mater. Process. Technol., 172(2006), No. 2, p. 202.

B. Yan, Study on Microstructural of Workpiece in Multi-wedge Cross Wedge Rolling [Dissertation], University of Science and Technology Beijing, Beijing, 2010, p. 2.

N. Zhang, B.Y. Wang, and J.G. Lin, Effect of cross wedge rolling on the microstructure of GH4169 alloy, Int. J. Miner. Metall. Mater., 19(2012), No. 9, p. 836.

Z.C. Sun, H. Yang, and X.Z. Ou, Effects of process parameters on microstructural evolution during hot ring rolling of AISI 5140 steel, Comput. Mater. Sci., 49(2010), No. 1, p. 134.

Z.C. Sun, H. Yang, and X.Z. Ou, Finite Element Analysis on Microstructural evolution of Hot Ring Rolling Process, Mater. Sci. Forum, 575-578(2008), p. 1455.

L.Y. Zhou, L. Wu, Y.Z. Liu, X.J. Cheng, and J.H. Sun, Microstructure and texture evolution of cold-rolled deep-drawing steel sheet during annealing, Int. J. Miner. Metall. Mater., 20(2013), No. 6, p. 541.

J. Ma, B. Wang, Z.L. Yang, G.X. Wu, J.Y. Zhang, and S.L. Zhao, Microstructure simulation of rapidly solidified ASP30 high-speed steel particles by gas atomization, Int. J. Miner. Metall. Mater., 23(2016), No. 3, p. 294.

S.X. Li, H.L. Zhang, S.L. Li, Y.L. Wang, F. Xue, and X.T. Wang, Effects of thermal aging temperature and Cr content on phase separation kinetics in Fe-Cr alloys simulated by the phase field method, Int. J. Miner. Metall. Mater., 20(2013), No. 11, p. 1067.

J. Luo, B. Wu, and M.Q. Li, 3D finite element simulation of microstructure evolution in blade forging of Ti-6Al-4V alloy based on the internal state variable models, Int. J. Miner. Metall. Mater., 19(2012), No. 2, p. 122.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, Jw., Yang, Cp., Zheng, Zh. et al. Influence of process parameters on the microstructural evolution of a rear axle tube during cross wedge rolling. Int J Miner Metall Mater 23, 1302–1314 (2016). https://doi.org/10.1007/s12613-016-1352-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-016-1352-7