Abstract

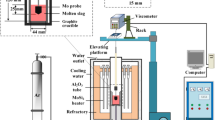

The viscosity of CaF2–CaO–Al2O3–MgO–(TiO2) slag was measured using a rotating crucible viscometer. Raman spectroscopy analysis was performed to correlate the viscosity to slag structure. The viscosity of the slag was found to decrease with increasing TiO2 content in the slag from 0 to 9.73wt%. The activation energy decreased from 95.16 kJ/mol to 79.40 kJ/mol with increasing TiO2 content in the slag. The introduction of TiO2 into the slag played a destructive role in Al–O–Al structural units and Q4 units by forming simpler structural units of Q2 and Ti2O6 4− chain. The amount of Al–O–Al significantly decreased with increasing TiO2 content. The relative fraction of Q4 units in the [AlO4]5−-tetrahedral units shows a decreasing trend, whereas the relative fraction of Q2 units and Ti2O6 4− chain increases with increasing TiO2 content accordingly. Consequently, the polymerization degree of the slag decreases with increasing TiO2 content. The variation in slag structure is consistent with the change in measured viscosity.

Similar content being viewed by others

References

K. Schwerdtfeger, W. Wepner, and G. Pateisky, Modelling of chemical reactions occurring during electroslag remelting: oxidation of titanium in stainless steel, Ironmaking Steelmaking, 5(1978), No. 3, p. 135.

Z.X. Xue, Y.X. Zheng, F. Jiang, Y.Q. Du, B.S. Guo, P. Lin, and C.B. Shi, Control of the surface quality and as-cast ingot and Ti loss during drawing-ingot-type electroslag rapid remelting of alloy 825, Spec. Steel, 37(2016), No. 4, p. 37.

X.C. Lu, Effect of titanium on surface formability of ESR super alloy ingot, Foundry, 51(2002), No. 6, p. 378.

C.B. Shi, J. Li, J.W. Cho, F. Jiang, and I.H. Jung, Effect of SiO2 on the crystallization behaviors and in-mold performance of CaF2−CaO−Al2O3 slags for drawing-ingot-type electroslag remelting, Metall. Mater. Trans. B, 46(2015), No. 5, p. 2110.

K. Zheng, Z.T. Zhang, L.L. Liu, and X.D. Wang, Investigation of the viscosity and structural properties of CaO–SiO2–TiO2 slags, Metall. Mater. Trans. B, 45(2014), No. 4, p. 1389.

H. Park, J.Y. Park, G.H. Kim, and I. Sohn, Effect of TiO2 on the viscosity and slag structure in blast furnace type slags, Steel Res. Int., 83(2012), No. 2, p. 150.

S.F. Zhang, X. Zhang, C.G. Bai, L.Y. Wen, and X.W. Lv, Effect of TiO2 content on the structure of CaO–SiO2–TiO2 system by molecular dynamics simulation, ISIJ Int., 53(2013), No. 7, p. 1131.

J.L. Li, Q.F. Shu, and K.C. Chou, Effect of TiO2 addition on viscosity and structure of CaO–Al2O3 based mold fluxes for high Al steel casting, Can. Metall. Q., 54(2015), No. 1, p. 85.

J.L. Liao, J. Li, X.D. Wang, and Z.T. Zhang, Influence of TiO2 and basicity on viscosity of Ti bearing slag, Ironmaking Steelmaking, 39(2012), No. 2, p. 133.

S.H. Shin, J.W. Cho, and S.H. Kim, Controlling the shear thinning property of calcium silicate melts by addition of Si3N4, J. Non Cryst. Solids, 423-424(2015), p. 45.

S.H. Shin, D.W. Yoon, J.W. Cho, and S.H. Kim, Controlling shear thinning property of lime silica based mold flux system with borate additive at 1623 K, J. Non Cryst. Solids, 425(2015), p. 83.

A. Shankar, M. Görnerup, A.K. Lahiri, and S. Seetharaman, Experimental investigation of the viscosities in CaO–SiO2–MgO–Al2O3 and CaO–SiO2–MgO–Al2O3–TiO2 slags, Metall. Mater. Trans. B, 38(2007), No. 6, p. 911.

Z. Wang, Q.F. Shu, and K.C. Chou, Viscosity of fluoride-free mold fluxes containing B2O3 and TiO2, Steel Res. Int., 84(2013), No. 8, p. 766.

N. Saito, N. Hori, K. Nakashima, and K. Mori, Viscosity of blast furnace type slags, Metall. Mater. Trans. B, 34(2003), No. 5, p. 509.

Y.L. Zhen, G.H. Zhang, and K.C. Chou, Influence of Al2O3/TiO2 ratio on viscosities and structure of CaO–MgO–Al2O3–SiO2–TiO2 melts, ISIJ Int., 54(2014), No. 4, p. 985.

Y. Sun, K. Zheng, J. Liao, X. Wang, and Z. Zhang, Effect of P2O5 addition on the viscosity and structure of titanium bearing blast furnace slags, ISIJ Int., 54(2014), No. 7, p. 1491.

A. Ohno and H.U. Ross, Optimum slag composition for the blast-furnace smelting of titaniferous ores, Can. Metall. Q., (1963), No. 3, p. 259.

Y.H. Gao, L.T. Bian, and Z.Y. Liang, Influence of B2O3 and TiO2 on viscosity of titanium-bearing blast furnace slag, Steel Res. Int., 86(2015), No. 4, p. 386.

H. Kim and I. Sohn, Effect of CaF2 and Li2O additives on the viscosity of CaO–SiO2–Na2O slags, ISIJ Int., 51(2011), No. 1, p. 1.

Y.M. Gao, S.B. Wang, C. Hong, X.J. Ma, and F. Yang, Effects of basicity and MgO content on the viscosity of the SiO2–CaO–MgO–9wt%Al2O3 slag system, Int. J. Miner. Metall. Mater., 21(2014), No. 4, p. 353.

H. Kim and I. Sohn, Influence of Li2O on the viscous behavior of CaO–Al2O3–12mass%Na2O–12 mass% CaF2 based slags, ISIJ Int., 52(2012), No. 1, p. 68.

B. Mysen and D. Neuville, Effect of temperature and TiO2 content on the structure of Na2Si2O5–Na2Ti2O5 melts and glasses, Geochim. Cosmochim. Acta, 59(1995), No. 2, p. 325.

B. Reynard and S.L. Webb, High-temperature Raman spectroscopy of Na2TiSi2O7 glass and melt: coordination of Ti4+ and nature of the configurational changes in the liquid, Eur. J. Mineral., 10(1998), No. 1, p. 49.

G.S. Henderson and M.E. Fleet, The structure of Ti silicate glasses by micro-Raman spectroscopy, Can. Mineral., 33(1995), p. 399.

K. Zheng, J.L Liao, X.D. Wang, and Z.T. Zhang, Raman spectroscopic study of the structural properties of CaO–MgO–SiO2–TiO2 slags, J. Non Cryst. Solids, 376(2013), No. 10, p. 209.

G.H. Kim and I. Sohn, Effect of Al2O3 on the viscosity and structure of calcium silicate-based melts containing Na2O and CaF2, J. Non Cryst. Solids, 358(2012), No. 12-13, p. 1530.

H. Kim, H. Matsuura, F. Tsukihashi, W. Wang, and D.J. Min, Effect of Al2O3 and CaO/SiO2 on the viscosity of calcium-silicate based slags containing 10 mass pct MgO, Metall. Mater. Trans. B, 44(2013), No. 1, p. 5.

Y. Sun, J. Liao, K. Zheng, X. Wang, and Z. Zhang, Effect of B2O3 on the structure and viscous behavior of Ti-bearing blast furnace slags, JOM, 66(2014), No. 10, p. 2168.

P. McMillan and B. Piriou, Raman spectroscopy of calcium aluminate glasses and crystals, J. Non Cryst. Solids, 55(1983), No. 2, p. 221.

M. Licheron, V. Montouillout, F. Millot, and D.R. Neuville, Raman and 27Al NMR structure investigations of aluminate glasses: (1−x) Al2O3–xMO, with M = Ca, Sr, Ba and 0.5 < x < 0.75, J. Non Cryst. Solids, 357(2011), No. 15, p. 2796.

P.L. Higby, R.J. Ginther, I.D. Aggarwal, and E.J. Friebele, Glass formation and thermal properties of low-silica calcium aluminosilicate glasses, J. Non Cryst. Solids, 126(1990), No. 3, p. 209.

T.S. Kim and J.H. Park, Structure-viscosity relationship of low-silica calcium aluminosilicate melts, ISIJ Int., 54(2014), No. 9, p. 2031.

G.H. Kim, C.S. Kim, and I. Sohn, Viscous behavior of alumina rich calcium-silicate based mold fluxes and its correlation to the melt structure, ISIJ Int., 53(2013), No. 1, p. 170.

D.R. Neuville, L. Cormier, and D. Massiot, Al environment in tectosilicate and peraluminous glasses: a 27Al MQ-MAS NMR, Raman, and XANES investigation, Geochim. Cosmochim. Acta, 68(2004), No. 24, p. 5071.

D.R. Neuville, G.S. Henderson, L. Cormier, and D. Massiot, The structure of crystals, glasses, and melts along the CaO–Al2O3 join: results from Raman, Al L- and K-edge X-ray absorption, and 27Al NMR spectroscopy, Am. Mineral., 95(2015), No. 10, p. 1580.

B.O. Mysen, F.J. Ryerson, and D. Virgo, The influence of TiO2 on the structure and derivative properties of silicate melts, Am. Mineral., 65(1980), p. 1150.

Acknowledgements

This work was financially supported by the Fundamental Research Funds for the Central Universities (Grant No. FRF-TP-15-010A2), and China Postdoctoral Science Foundation (Grant No. 2016T90035).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, Cb., Zheng, Dl., Shin, Sh. et al. Effect of TiO2 on the viscosity and structure of low-fluoride slag used for electroslag remelting of Ti-containing steels. Int J Miner Metall Mater 24, 18–24 (2017). https://doi.org/10.1007/s12613-017-1374-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-017-1374-9