Abstract

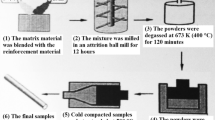

Deep rolling is one of the most widely used surface mechanical treatments among several methods used to generate compressive residual stress. This process is usually used for axisymmetric components and can lead to improvements of the surface quality, dimensional accuracy, and mechanical properties. In this study, we deduced the appropriate deep rolling parameters for Al−3vol%SiC nanocomposite samples using roughness and microhardness measurements. The nanocomposite samples were fabricated using a combination of mechanical milling, cold pressing, and hot extrusion techniques. Density measurements indicated acceptable densification of the samples, with no porosity. The results of tensile tests showed that the samples are sufficiently strong for the deep rolling process and also indicated near 50% improvement of tensile strength after incorporating SiC nanoparticle reinforcements. The effects of some important rolling parameters, including the penetration depth, rotation speed, feed rate, and the number of passes, on the surface quality and microhardness were also investigated. The results demonstrated that decreasing the feed rate and increasing the number of passes can lead to greater surface hardness and lower surface roughness.

Similar content being viewed by others

References

A. Atrian, G.H. Majzoobi, M.H. Enayati, and H. Bakhtiari, Mechanical and microstructural characterization of Al7075/SiC nanocomposites fabricated by dynamic compaction, Int. J. Miner. Metall. Mater., 21(2014), No. 3, p. 295.

A. Atrian, G.H. Majzoobi, M.H. Enayati, and H. Bakhtiari, A comparative study on hot dynamic compaction and quasi-static hot pressing of Al7075/SiCnp nanocomposite, Adv. Powder Technol., 26(2015), No. 1, p. 73.

G.H. Majzoobi, A. Atrian, and M.H. Enayati, Tribological properties of Al7075-SiC nanocomposite prepared by hot dynamic compaction, Compos. Interfaces, 22(2015), No. 7, p. 579.

O. El-Kady and A. Fathy, Effect of SiC particle size on the physical and mechanical properties of extruded Al matrix nanocomposites, Mater. Des., 54(2014), p. 348.

M. Jafari, M.H. Abbasi, M.H. Enayati, and F. Karimzadeh, Mechanical properties of nanostructured Al2024–MWCNT composite prepared by optimized mechanical milling and hot pressing methods, Adv. Powder Technol., 23(2012), No. 2, p. 205.

H. Ghasemi Yazdabadi, A. Ekrami, H.S. Kim, and A. Simchi, An investigation on the fatigue fracture of P/M Al-SiC nanocomposites, Metall. Mater. Trans. A, 44(2013), No. 6, p. 2662.

G.H. Majzoobi, H. Bakhtiari, A. Atrian, M.K. Pipelzadeh, and S.J. Hardy, Warm dynamic compaction of Al6061/SiC nanocomposite powders, [in] Proceedings of the Institution of Mechanical Engineers Part L, 2015, p. 1.

S.A. Sajjadi, H.R. Ezatpour, and H. Beygi, Microstructure and mechanical properties of Al–Al2O3 micro and nano composites fabricated by stir casting, Mater. Sci. Eng. A, 528(2011), No. 29-30, p. 8765.

S.A. Sajjadi, H.R. Ezatpour, and M. Torabi Parizi, Comparison of microstructure and mechanical properties of A356 aluminum alloy/Al2O3 composites fabricated by stir and compo-casting processes, Mater. Des., 34(2012), p. 106.

S.A. Sajjadi, M. Torabi Parizi, H.R. Ezatpour, and A. Sedghi, Fabrication of A356 composite reinforced with micro and nano Al2O3 particles by a developed compocasting method and study of its properties, J. Alloys Compd., 511(2012), No. 1, p. 226.

A. Abdollahi, A. Alizadeh, and H.R. Baharvandi, Dry sliding tribological behavior and mechanical properties of Al2024–5wt.%B4C nanocomposite produced by mechanical milling and hot extrusion, Mater. Des., 55(2014), p. 471.

A. Abdollahi, A. Alizadeh, and H.R. Baharvandi, Comparative studies on the microstructure and mechanical properties of bimodal and trimodal Al2024 based composites, Mater. Sci. Eng. A, 608(2014), p. 139.

A. Alizadeh and E. Taheri-Nassaj, Mechanical properties and wear behavior of Al–2wt.% Cu alloy composites reinforced by B4C nanoparticles and fabricated by mechanical milling and hot extrusion, Mater. Charact., 67(2012), p. 119.

A. Fathy, A. Sadoun, and M. Abdelhameed, Effect of matrix/ reinforcement particle size ratio (PSR) on the mechanical properties of extruded Al–SiC composites, Int. J. Adv. Manuf. Technol., 73(2014), No. 5, p. 1049.

R. Senthilkumar, N. Arunkumar, and M. Manzoor Hussian, A comparative study on low cycle fatigue behaviour of nano and micro Al2O3 reinforced AA2014 particulate hybrid composites, Results Phys., 5(2015), p. 273.

M. Tavoosi, S. Rizaneh, and G.H. Borhani, The effect of Al2O3–TiB2/Fe complex reinforcement on wear and mechanical properties of Al-matrix composites, Trans. Indian Inst. Met., 70(2017), No. 5, p. 1215.

S. Rizaneh, G.H. Borhani, and M. Tavoosi, Synthesis and characterization of Al (Al2O3–TiB2/Fe) nanocomposite by means of mechanical alloying and hot extrusion processes, Adv. Powder Technol., 25(2014), No. 6, p. 1693.

A.M. Abrão, B. Denkena, J. Köhler, B. Breidenstein, and T. Mörke, The inducement of residual stress through deep rolling of AISI 1060 steel and its subsequent relaxation under cyclic loading, Int. J. Adv. Manuf. Technol., 79(2015), No. 9, p. 1939.

G.H. Majzoobi, F. Zare Jouneghani, and E. Khademi, Experimental and numerical studies on the effect of deep rolling on bending fretting fatigue resistance of Al7075, Int. J. Adv. Manuf. Technol., 82(2016), No. 9, p. 2137.

I. Altenbergr, Deep rolling—the past, the present and the future, [in] Proceedings of the 9th International Conference on Shot Peening, Paris, 2005, p. 144.

G.H. Majzoobi, J. Nemati, A.J. Novin Rooz, and G.H. Farrahi, Modification of fretting fatigue behavior of AL7075–T6 alloy by the application of titanium coating using IBED technique and shot peening, Tribol. Int., 42(2009), No. 1, p. 121.

Y.S. Nam, U. Jeon, H.K. Yoon, B.C. Shin, and J.H. Byun, Use of response surface methodology for shot peening process optimization of an aircraft structural part, Int. J. Adv. Manuf. Technol., 87(2016), No. 9, p. 2967.

M. Beghini, L. Bertini, B.D. Monelli, C. Santus, and M. Bandini, Experimental parameter sensitivity analysis of residual stresses induced by deep rolling on 7075-T6 aluminium alloy, Surf. Coat. Technol., 254(2014), p. 175.

P. Prabhu, S.M. Kulkarni, and S.S. Sharma, An experimental investigation on the effect of deep cold rolling parameters on surface roughness and hardness of AISI 4140 steel, World Acad. Sci. Eng. Technol., 60(2011), p. 1593.

P.R. Prabhu, S.M. Kulkarni, and S.S. Sharma, Experimental investigations of process parameters influence on surface roughness in deep cold rolling of AISI 4140 steel, IJRET, 1(2012), No. 3, p. 159.

R.K. Nalla, I. Altenberger, U. Noster, G.Y. Liu, B. Scholtes, and R.O. Ritchie, On the influence of mechanical surface treatments—deep rolling and laser shock peening—on the fatigue behavior of Ti–6Al–4V at ambient and elevated temperatures, Mater. Sci. Eng. A, 355(2003), No. 1-2, p. 216.

M. Ebrahimi, S. Amini, and S.M. Mahdavi, The investigation of laser shock peening effects on corrosion and hardness properties of ANSI 316L stainless steel, Int. J. Adv. Manuf. Technol., 88(2016), No. 5, p. 1557.

M.L. Cheng, D.Y. Zhang, H.W. Chen, W. Qin, and J.S Li., Surface nanocrystallization and its effect on fatigue performance of high-strength materials treated by ultrasonic rolling process, Int. J. Adv. Manuf. Technol., 83(2016), No. 1, p. 123.

L.X. Lu, J. Sun, L. Li, and Q.C. Xiong, Study on surface characteristics of 7050-T7451 aluminum alloy by ultrasonic surface rolling process, Int. J. Adv. Manuf. Technol., 87(2016), No. 9, p. 2533.

X.L. Yuan, Y.W. Sun, C.Y. Li, and W.R. Liu, Experimental investigation into the effect of low plasticity burnishing parameters on the surface integrity of TA2, Int. J. Adv. Manuf. Technol., 88(2017), No. 1, p. 1089.

X.L. Yuan, Y.W. Sun, L.S. Gao, and S.L. Jiang, Effect of roller burnishing process parameters on the surface roughness and microhardness for TA2 alloy, Int. J. Adv. Manuf. Technol., 85(2016), No. 5, p. 1373.

A. Rodríguez, L.N. López de Lacalle, A. Celaya, A. Lamikiz, and J. Albizuri, Surface improvement of shafts by the deep ball-burnishing technique, Surf. Coat. Technol., 206(2012), No. 11-12, p. 2817.

G.H. Majzoobi, K. Azadikhah, and J. Nemati, The effects of deep rolling and shot peening on fretting fatigue resistance of Aluminum-7075-T6, Mater. Sci. Eng. A, 516(2009), No. 1-2, p. 235.

C.Y. Seemikeri, P.K. Brahmankar, and S.B. Mahagaonkar, Investigations on surface integrity of AISI 1045 using LPB tool, Tribol. Int., 41(2008), No. 8, p. 724.

M.H. El-Axir, An investigation into roller burnishing, Int. J. Mach. Tools Manuf., 40(2000), No. 11, p. 1603.

L. Luca, S. Neagu-Ventzel, and I. Marinescu, Effects of working parameters on surface finish in ball-burnishing of hardened steels, Precis. Eng., 29(2005), No. 2, p. 253.

P.R. Taleghani, S.R. Bakhshi, M. Erfanmanesh, G.H. Borhani, and R. Vafaei, Improvement of MoSi2 oxidation resistance via boron addition: Fabrication of MoB/MoSi2 composite by mechanical alloying and subsequent reactive sintering, Powder Technol., 254(2014), p. 241.

S. Kumar, Technology of Metal Forming Processes, PHI Learning, New Delhi, 2008.

A.M. Abrão, B. Denkena, B. Breidenstein, and T. Mörke, Surface and subsurface alterations induced by deep rolling of hardened AISI 1060 steel, Prod. Eng., 8(2014), No. 5, p. 551.

A.R.F. Pieralini, C.M. Benjamin, R.F. Ribeiro, G. Scaf, and G.L. Adabo, The effect of coating patterns with spinel-based investment on the castability and porosity of titanium cast into three phosphate-bonded investments, J. Prosthodont., 19(2010), No. 7, p. 517.

C. Suryanarayana, Mechanical alloying and milling, Prog. Mater. Sci., 46(2001), No. 1-2, p. 1.

D.L. Zhang, Processing of advanced materials using high-energy mechanical milling, Prog. Mater. Sci., 49(2004), No. 3-4, p. 537.

A.R. Othman, A. Sardarinejad, and A.K. Masrom, Effect of milling parameters on mechanical alloying of aluminum powders, Int. J. Adv. Manuf. Technol., 76(2015), No. 5, p. 1319.

S.S. Razavi-Tousi, R. Yazdani-Rad, and S.A. Manafi, Effect of volume fraction and particle size of alumina reinforcement on compaction and densification behavior of Al–Al2O3 nanocomposites, Mater. Sci. Eng. A, 528(2011), No. 3, p. 1105.

G.H. Majzoobi, A. Atrian, and M.K. Pipelzadeh, Effect of densification rate on consolidation and properties of Al7075–B4C composite powder, Powder Metall., 58(2015), No. 4, p. 281.

Z. Zhang and D.L. Chen, Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength, Scripta Mater., 54(2006), No. 7, p. 1321.

J.F.W. Galyer and C.R. Shotbolt, Metrology for Engineers, Cassell, London, 1990.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sattari, S., Atrian, A. Effects of the deep rolling process on the surface roughness and properties of an Al−3vol%SiC nanoparticle nanocomposite fabricated by mechanical milling and hot extrusion. Int J Miner Metall Mater 24, 814–825 (2017). https://doi.org/10.1007/s12613-017-1465-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-017-1465-7