Abstract

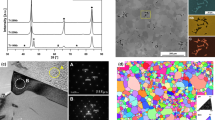

Ti2AlNb-based alloys with 0.0wt%, 0.6wt%, and 2.0wt% carbon nanotube (CNT) addition were fabricated from spherical Ti–22Al–25Nb powder by sintering in the B2 single-phase region. Phase identification and microstructural examination were performed to evaluate the effect of carbon addition on the hardness of the alloys. Carbon was either in a soluble state or in carbide form depending on its concentration. The acicular carbides formed around 1050°C were identified as TiC and facilitated the transformation of α2 + B2 → O. The TiC was located within the acicular O phase. The surrounding O phase was distributed in certain orientations with angles of 65° or 90° O phase particles. The obtained alloy was composed of acicular O, Widmanstatten B2 + O, and acicular TiC. As a result of the precipitation of carbides as well as the O phase, the hardness of the alloy with 2.0wt% CNT addition increased to HV 429 ± 9.

Similar content being viewed by others

References

D. Banerjee and J.C. Williams, Perspectives on titanium science and technology, Acta Mater., 61(2013), No. 3, p. 844.

A. Nocivin, I. Cinca, D. Raducanu, V.D. Cojocaru, and I.A. Popovici, Mechanical properties of a Gum-type Ti-Nb-Zr-Fe-O alloy, Int. J. Miner. Metall. Mater., 24(2017), No. 8, p. 909.

Y.Y. Zong, B. Shao, Y.T. Tian, and D.B. Shan, A study of the sharp yield point of a Ti–22Al–25Nb alloy, J. Alloys Compd., 701(2017), p. 727.

X. Lu, L.H. Zhao, L.P. Zhu, B. Zhang, and X.H. Qu, High-temperature mechanical properties and deformation behavior of high Nb containing TiAl alloys fabricated by spark plasma sintering, Int. J. Miner. Metall. Mater., 19(2012), No. 4, p. 354.

H.B. Feng, D.C. Jia, and Y. Zhou, Spark plasma sintering reaction synthesized TiB reinforced titanium matrix composites, Composites Part A, 36(2005), No. 5, p. 558.

S. Ranganath and R.S. Mishra, Steady state creep behaviour of particulate-reinforced titanium matrix composites, Acta Mater., 44(1996), No. 3, p. 927.

Y.Y. Liu, Z.K. Yao, H.Z. Guo, and H.H. Yang, Microstructure and property of the Ti–24Al–15Nb–1.5 Mo/TC11 joint welded by electron beam welding, Int. J. Miner. Metall. Mater., 16(2009), No. 5, p.568.

H.B. Yang, T. Gao, H.C. Wang, J.F. Nie, and X.F Liu, Influence of C/Ti stoichiometry in TiCx on the grain refinement efficiency of Al–Ti–C master alloy, J. Mater. Sci. Technol., 33(2017), No. 7, p. 616.

S.C. Tjong and Z.Y. Ma, Microstructural and mechanical characteristics of in situ metal matrix composites, Mater. Sci. Eng. R, 29(2000), No. 3-4, p. 49.

B. Ghosh and S.K. Pradhan, Microstructure characterization of nanocrystalline TiC synthesized by mechanical alloying, Mater. Chem. Phys., 120(2010), No. 2-3, p. 537.

M. Razavi, M.R. Rahimipour, and A.H. Rajabi-Zamani, Effect of nanocrystalline TiC powder addition on the hardness and wear resistance of cast iron, Mater. Sci. Eng. A, 454-455(2007), p. 144.

E. Zhang, S.Y. Zeng, and B. Wang, Preparation and microstructure of in situ particle reinforced titanium matrix alloy, J. Mater. Process. Technol., 125-126(2002), p. 103.

I.A.M. Arif, M.K. Talari, A.L. Anis, M.H. Ismail, and N.K. Babu, Grain refinement, microstructural and hardness investigation of C added Ti–15–3 Alloys prepared by argon arc melting, Trans. Indian Inst. Met., 70(2017), No. 3, p. 861.

R. Sarkar, P. Ghosal, K. Muraleedharan, T.K. Nandy, and K.K. Ray, Effect of boron and carbon addition on microstructure and mechanical properties of Ti-15-3 alloy, Mater. Sci. Eng. A, 528(2011), No. 13-14, p. 4819.

R. Banoth, R. Sarkar, A. Bhattacharjee, T.K. Nandy, and G. V.S.N Rao, Effect of boron and carbon addition on microstructure and mechanical properties of metastable beta titanium alloys, Mater. Des., 67(2015), p. 50.

N.K. Babu, K. Kallip, M. Leparoux, M.K. Talari, K.A. Alogab, and N.M. Alqahtani, Phase evolution during high energy cube milling of Ti–6Al–4V0.5 vol% TiC powders using heptane and tin as process control agents (PCAs), Adv. Eng. Mater., 19(2017), No. 2, art. No. 1600662.

Q.M. Wang, K. Zhang, J. Gong, Y.Y. Cui, C. Sun, and L.S. Wen, NiCoCrAlY coatings with and without an Al2O3/Al interlayer on an orthorhombic Ti2AlNb-based alloy: Oxidation and interdiffusion behaviors, Acta Mater., 55(2007), No. 4, p.1427.

H.P. Duan, H.X. Xu, W.H. Su, Y.B. Ke, Z.Q. Liu, and H.H. Song, Effect of oxygen on the microstructure and mechanical properties of Ti–23Nb–0.7Ta–2Zr alloy, Int. J. Miner. Metall. Mater., 19(2012), No. 12, p. 1128

H. Zhang, H.J. Li, Q.Y. Guo, Y.C. Liu, and L.M. Yu, Hot deformation behavior of Ti–22Al–25Nb alloy by processing maps and kinetic analysis, J. Mater. Res., 31(2016), No. 12, p. 1764.

B. Shao, Y.Y. Zong, D.S. Wen, Y.T. Tian, and D.B. Shan, Investigation of the phase transformations in Ti–22Al–25Nb alloy, Mater. Charact., 114(2016), p. 75.

Y.C. Liu, F. Lan, G.C. Yang, and Y.H. Zhu, Microstructural evolution of rapidly solidified Ti–Al peritectic alloy, J. Cryst. Growth, 271(2004), No. 1-2, p. 313.

C.J. Cowen and C.J. Boehlert, Comparison of the microstructure, tensile, and creep behavior for Ti–22Al–26Nb (at. pct) and Ti–22Al–26Nb–5B (at. pct), Metall. Mater. Trans. A, 38(2007), No. 1, p. 26.

T.K. Nandy, R.S. Mishra, and D. Banerjee, Creep behaviour of an orthorhombic phase in a Ti–Al–Nb alloy, Scripta Met. Mater., 28(1993), No. 5, p. 569.

C.J. Boehlert, B.S. Majumdar, V. Seetharaman, and D.B. Miracle, Part I. The microstructural evolution in Ti–Al–Nb O + BCC orthorhombic alloys, Metall, Mater. Trans. A, 30(1999), No. 9, p. 2305.

I.W. Hall and C.Y. Ni, Thermal stability of an SCS-6/Ti–22Al–23Nb composite, Mater. Sci. Eng. A, 192-193(1995), p. 987.

Y.Q. Yang, Y. Zhu, Z.J. Ma, and Y. Chen, Formation of interfacial reaction products in SCS-6SiC/Ti2AlNb composites, Scripta Mater., 51(2004), No. 5, p. 385.

X. Luo, Y.Q. Wang, Y.Q. Yang, M.X. Zhang, B. Huang, S. Liu, and N. Jin, Effect of C/Mo duplex coating on the interface and tensile strength of SiCf/Ti–21Al–29Nb composites, J. Alloys Compd., 721(2017), p. 653.

P.R. Smith, A.H. Rosenberger, M.J. Shepard, and R. Wheeler, Review AP/M approach for the fabrication of an orthorhombic titanium aluminide for MMC applications, J. Mater. Sci., 35(2000), No. 13, p. 3169.

J. Wu, L. Xu, Z.G. Lu, B. Lu, Y.Y. Cui, and R. Yang, Microstructure design and heat response of powder metallurgy Ti2AlNb alloys, J. Mater. Sci. Technol., 31(2015), No. 12, p. 1251.

P. Davies, R. Pederson, M. Coleman, and S. Birosca, The hierarchy of microstructure parameters affecting the tensile ductility in centrifugally cast and forged Ti-834 alloy during high temperature exposure in air, Acta Mater., 117(2016), p. 51.

S. Gorsse, Y. L. Petitcorps, S. Matar, and F. Rebillat, Investigation of the Young's modulus of TiB needles in situ produced in titanium matrix composite, Mater. Sci. Eng. A, 340(2003), No. 1-2, p. 80.

H. Feng, D. Jia, and Y. Zhou, Influence factors of ball milling process on BE powder for reaction sintering of TiB/Ti-4.0Fe-7.3Mo composite, J. Mater. Process. Technol., 182(2007), No. 1-2, p. 79.

H.Z. Niu, Y.F. Chen, D.L. Zhang, Y.S. Zhang, J.W. Lu, W. Zhang, and P.X. Zhang, Fabrication of a powder metallurgy Ti2AlNb-based alloy by spark plasma sintering and associated microstructure optimization, Mater. Des., 89(2016), p. 823.

M. Li, Q. Cai, Y.C. Liu, Z.Q. Ma, Z.M. Wang, Y. Huang, and J.X. Yu, Dual structure O + B2 for enhancement of hardness in furnace-cooled Ti2AlNb-based alloys by powder metallurgy, Adv. Powder Technol., 28(2017), No. 7, p. 1719.

M. Li, Q. Cai, Y. Liu, Z. Ma, Z. Wang, Y. Huang, and H. Li, Formation of fine B2/β + O structure and enhancement of hardness in the aged Ti2AlNb-Based alloys prepared by spark plasma sintering, Metall. Mater. Trans. A, 48(2017), No. 9, p. 4365.

M. Behera, S. Raju, R. Mythili, and S. Saroja, Study of kinetics of α⇔ β phase transformation in Ti–4.4 mass% Ta–1.9 mass% Nb alloy using differential scanning calorimetry, J. Therm. Anal. Calorim., 124(2016), No. 3, p. 1217.

M.I.D. Barros, D. Rats, L. Vandenbulcke, and G. Farges, Influence of internal diffusion barriers on carbon diffusion in pure titanium and Ti–6Al–4V during diamond deposition, Diamond Relat. Mater., 8(1999), No. 6, p. 1022.

M. Hansen, K. Anderko, and H.W. Salzberg, Constitution of binary alloys, J. Electrochem. Soc., 105(1958), No. 12, p. 260.

K. Muraleedharan, D. Banerjee, S. Banerjee, and S. Lele, The α2-to-O transformation in Ti–Al–Nb alloys, Philos. Mag. A., 5(1995), No. 5, p. 1011.

J. Roger, B. Gardiola, J. Andrieux, J.C. Viala, and O. Dezellus, Synthesis of Ti matrix composites reinforced with TiC particles: thermodynamic equilibrium and change in microstructure, J. Mater. Sci., 52(2017), No. 7, p. 4129.

H.M. Rietveld, A profile refinement method for nuclear and magnetic structures, J. Appl. Crystallogr., 2(1969), No. 2, p. 65.

W. Wang, W.D. Zeng, C. Xue, X.B. Liang, and J.W. Zhang, Quantitative analysis of the effect of heat treatment on microstructural evolution and microhardness of an isothermally forged Ti–22Al–25Nb (at.%) orthorhombic alloy, Intermetallics, 45(2014), p. 29.

Y. Wang, X.Q. Cai, Z.W. Yang, D.P. Wang, X.G. Liu, and Y.C. Liu, Effects of Nb content in Ti–Ni–Nb brazing alloys on the microstructure and mechanical properties of Ti–22Al–25Nb alloy brazed joints, J. Mater. Sci. Technol., 33(2017), No. 7, p. 682.

B. Shao, S.X. Wan, D.B. Shan, B. Guo, and Y.Y. Zong, Hydrogen-induced improvement of the cylindrical drawing properties of a Ti–22Al–25Nb alloy, Adv. Eng. Mater., 19(2016), No. 3, art. No. 1600621.

Acknowledgements

The authors are grateful to the China National Funds for Distinguished Young Scientists (No. 51325401), the National Natural Science Foundation of China (Nos. 51474156 and U1660201), and the National Magnetic Confinement Fusion Energy Research Program of China (No. 2014GB125006) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Yr., Cai, Q., Liu, Yc. et al. Evaluation of precipitation hardening in TiC-reinforced Ti2AlNb-based alloys. Int J Miner Metall Mater 25, 453–458 (2018). https://doi.org/10.1007/s12613-018-1591-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-018-1591-x