Abstract

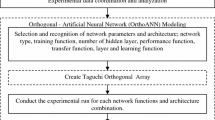

In the present investigation two smart prediction tools, namely the general regression neural network (GRNN) and multiple regression analysis (MRA) models were developed to predict and compare some of the key machinability aspects like average kerf width, average surface roughness and material removal rate in the wire electrical discharge machining process of titanium grade 6. Pulse-on time, pulse-off time, wire feed and wire tension were considered as machining variables to develop the predictive model. In order to curtail cross-validation error in GRNN, optimized kernel bandwidth was utilized using the grid search method. The neural network and regression models were trained, validated and tested with measured data. A mathematical model was developed using multiple regression analysis. The ANOVA test was also conducted to determine the significant parameters affecting the responses. The results indicated that the predicted responses lie within ± 5% and ± 10% error for GRNN and MRA, respectively, which suggests that the GRNN model is more reliable and adequate than the regression model. A comparative study with previous research work was also done to confirm the novelty along with application potential of the proposed model.

Similar content being viewed by others

Abbreviations

- NTM:

-

non-traditional machining

- WEDM:

-

wire electrical discharge machining

- EDM:

-

electrical discharge machining

- MR:

-

multiple regression

- MRA:

-

multiple regression analysis

- CNC:

-

computer numerical control

- TON :

-

pulse-on time

- TOFF :

-

pulse-off time

- WF:

-

wire feed

- WT:

-

wire tension

- MRR:

-

material removal rate

- EDS:

-

energy dispersive spectroscopy

- ANN:

-

artificial neural network

- GRNN:

-

general regression neural network

- NSGA-II:

-

non-dominated sorting genetic algorithm-II

- BPNN:

-

back propagation neural network

- FFBPNN:

-

feed forward back propagation neural network

- GA:

-

genetic algorithm

- PSO:

-

particle swarm optimization

- AWJM:

-

abrasive waterjet machining

- ANOVA:

-

analysis of variance

- GRA:

-

grey relational analysis

- TWR:

-

tool wear rate

- WWR:

-

weight wear ratio

- RSM:

-

response surface methodology

- HSLA:

-

high strength low alloy

- BPN:

-

back propagation

- EDS:

-

energy dispersive spectroscopy

- SEM:

-

scanning electron microscope

- PH:

-

precipitation hardening

- NF:

-

neuro fuzzy

References

Lazarenko B (1943) To invert the effect of wear on electric power contacts. Dissertation of the All-Union Institute for Electro Technique in Moscow/CCCP, Russian

Singh V, Bhandari R, Yadav VK (2017) An experimental investigation on machining parameters of AISI D2 steel using WEDM. Int J Adv Manuf Technol 93(1–4):203–214

Manjaiah M, Narendranath S, Basavarajappa S (2016) Wire electro discharge machining performance of TiNiCu shape memory alloy. Silicon 8(3):467–475

Majumder H, Paul T, Dey V, Dutta P, Saha A (2017) Use of PCA-grey analysis and RSM to model cutting time and surface finish of Inconel 800 during wire electro discharge cutting. Measurement 107:19–30

Daneshmand S, Monfared V, Neyestanak AAL (2017) Effect of tool rotational and Al2O3 powder in electro discharge machining characteristics of NiTi-60 shape memory alloy. Silicon 9(2):273–283

Sharma P, Chakradhar D, Narendranath S (2017) Analysis and Optimization of WEDM Performance Characteristics of Inconel 706 for Aerospace Application. Silicon:1–0. https://doi.org/10.1007/s12633-017-9549-6

Kumar H, Manna A, Kumar R (2017) Modeling of Process Parameters for Surface Roughness and Analysis of Machined Surface in WEDM of Al/SiC-MMC. Trans Indian Inst Met.:1–4. https://doi.org/10.1007/s12666-017-1159-x

Tosun N, Cogun C, Tosun G (2004) A study on kerf and material removal rate in wire electrical discharge machining based on Taguchi method. J Mater Process Technol 152(3):316–322

VinothKumar S, PradeepKumar M (2017) Experimental Investigation and Optimization of Machining Process Parameters in AISI D2 Steel Under Conventional EDM and Cryogenically Cooled EDM Process. Trans Indian Inst Met:1 70(9):2293–301

Panda BN, Bahubalendruni MR, Biswal BB (2015) A general regression neural network approach for the evaluation of compressive strength of FDM prototypes. Neural Comput Appl 26(5):1129–1136

Özener O, Yüksek L, Özkan M (2013) Artificial neural network approach to predicting engine-out emissions and performance parameters of a turbo charged diesel engine. Therm Sci 17(1):153–166

Oğuz H, Sartas I, Baydan HE (2010) Prediction of diesel engine performance using biofuels with artificial neural network. Expert Syst Appl 37(9):6579–6586

Yadav RN, Yadava V (2015) Application of soft computing techniques for modeling and optimization of slotted-electrical discharge diamond face grinding process. Trans Indian Inst Met 68(5):981–990

Asiltürk I, Çunkaş M (2011) Modeling and prediction of surface roughness in turning operations using artificial neural network and multiple regression method. Expert Syst Appl 38(5):5826–5832

Ibrić S, Jovanović M, Djurić Z, Parojčić J, Solomun L (2002) The application of generalized regression neural network in the modeling and optimization of aspirin extended release tablets with EudragitRS PO as matrix substance. J Control Release 82(2):213–222

Cigizoglu HK, Alp M (2006) Generalized regression neural network in modelling river sediment yield. Adv Eng Softw 37(2):63–68

Celikoglu HB, Cigizoglu HK (2007) Public transportation trip flow modeling with generalized regression neural networks. Adv Eng Softw 38(2):71–79

Pradhan M, Das R (2015) Application of a general regression neural network for predicting radial overcut in electrical discharge machining of AISI D2 tool steel. Int J Mach Mach Mater 17(3-4):355–369

Kim B, Kim S, Kim K (2003) Modelling of plasma etching using a generalized regression neural network. Vacuum 71(4):497–503

Rooki R (2016) Application of general regression neural network (GRNN) for indirect measuring pressure loss of Herschel–Bulkley drilling fluids in oil drilling. Measurement 85:184–191

Alilou VK, Yaghmaee F (2015) Application of GRNN neural network in non-texture image inpainting and restoration. Pattern Recogn Lett 62:24–31

Schaffer JD, Park JW, Barnes E, Lu Q, Qiao X, Deng Y, Li Y, Land WH (2012) GRNN ensemble classifier for Lung Cancer prognosis using only demographic and TNM features. Procedia Comput Sci 12:450–455

Bendu H, Deepak B, Murugan S (2017) Multi-objective optimization of ethanol fuelled HCCI engine performance using hybrid GRNN–PSO. Appl Energy 187:601–611

Kulkarni SG, Chaudhary AK, Nandi S, Tambe SS, Kulkarni BD (2004) Modeling and monitoring of batch processes using principal component analysis (PCA) assisted generalized regression neural networks (GRNN). Biochem Eng J 18(3):193–210

De BP, Kar R, Mandal D, Ghoshal SP (2016) An efficient design of CMOS comparator and folded cascode op-amp circuits using particle swarm optimization with an aging leader and challengers algorithm. Int J Mach Learn Cybern 7(2):325–344

De BP, Kar R, Mandal D, Ghoshal S (2017) PSO with aging leader and challengers for optimal design of high speed symmetric switching CMOS inverter. Int J Mach Learn Cybern 8(4):1403–1422

Kumar A, Majumder H, Vivekananda K, Maity K (2017) NSGA-II approach for multi-objective optimization of wire electrical discharge machining process parameter on inconel 718. Mater Today: Proc 4(2):2194–2202

De BP, Kar R, Mandal D, Ghoshal SP (2015) Optimal selection of components value for analog active filter design using simplex particle swarm optimization. Int J Mach Learn Cybern 6(4):621–636

De BP, Kar R, Mandal D, Ghoshal SP (2016) Optimal design of high speed symmetric switching CMOS inverter using hybrid harmony search with differential evolution. Soft Comput 20(9):3699–3717

De BP, Kar R, Mandal D, Ghoshal S (2016) Soft computing-based approach for optimal design of on-chip comparator and folded-cascode op-amp using colliding bodies optimization. Int J Numer Model Electron Netw Devices Fields 29(5):873–896

De BP, Kar R, Mandal D, Ghoshal S (2015) Optimal analog active filter design using craziness-based particle swarm optimization algorithm. Int J Numer Model Electron Netw Devices Fields 28(5):593–609

Das R, Pradhan M (2014) General regression neural network and back propagation neural network modeling for predicting radial overcut in EDM: A comparative study. World Acad Sci Eng Technol Int J Mech Aerosp Ind Mechatron Manuf Eng 8(4):799–805

Shakeri S, Ghassemi A, Hassani M, Hajian A (2016) Investigation of material removal rate and surface roughness in wire electrical discharge machining process for cementation alloy steel using artificial neural network. Int J Adv Manuf Technol 82(1-4):549–557

Lin B -T, Jean M -D, Chou J -H (2007) Using response surface methodology for optimizing deposited partially stabilized zirconia in plasma spraying. Appl Surf Sci 253(6):3254–3262

Çaydaş U, Hasçalk A (2008) A study on surface roughness in abrasive waterjet machining process using artificial neural networks and regression analysis method. J Mater Process Technol 202(1):574–582

Kuriakose S, Shunmugam M (2005) Multi-objective optimization of wire-electro discharge machining process by non-dominated sorting genetic algorithm. J Mater Process Technol 170(1):133–141

Sivasankar S, Jeyapaul R (2012) Application of grey entropy and regression analysis for modelling and prediction on tool materials performance during edm of hot pressed ZrB 2 at different duty cycles. Procedia Eng 38:3977–3991

Sivaprakasam P, Hariharan P, Gowri S (2014) Modeling and analysis of micro-WEDM process of titanium alloy (Ti–6Al–4V) using response surface approach. Eng Sci Technol Int J 17(4):227–235

Khan MAR, Rahman M (2013) Development of regression equation for surface finish and analysis of surface integrity in EDM. Int J Mech Aerosp Ind Mechatron Eng 7(3):178–183

Sharma N, Khanna R, Gupta RD (2015) WEDM process variables investigation for HSLA by response surface methodology and genetic algorithm. Eng Sci Technol Int J 18(2):171–177

Reddy PVB, Kumar CV, Reddy KH (2010) Modeling of wire EDM process using back propagation (BPN) and General Regression Neural Networks (GRNN). In: Frontiers in Automobile and Mechanical Engineering (FAME). IEEE, pp 317–321

Alias A, Abdullah B, Abbas NM (2012) Influence of machine feed rate in WEDM of titanium Ti-6Al-4V with constant current (6A) using brass wire. Procedia Eng 41:1806–1811

Specht DF (1991) A general regression neural network. IEEE Trans Neural Netw 2(6):568–576

Nawi NM, Atomi WH, Rehman M (2013) The effect of data pre-processing on optimized training of artificial neural networks. Procedia Technol 11:32–39

Bendu H, Deepak B, Murugan S (2016) Application of GRNN for the prediction of performance and exhaust emissions in HCCI engine using ethanol. Energy Convers Manag 122:165–173

Chen H -C, Lin J -C, Yang Y -K, Tsai C -H (2010) Optimization of wire electrical discharge machining for pure tungsten using a neural network integrated simulated annealing approach. Expert Syst Appl 37(10):7147–7153

Abinash KS, Siddhartha R, Mandal NK Study on Kerf Width in Wire-EDM Based on Taguchi Method. In: Applied Mechanics and Materials, 2012. Trans Tech Publ, pp 1808-1816

Sadeghi M, Razavi H, Esmaeilzadeh A, Kolahan F (2011) Optimization of cutting conditions in WEDM process using regression modelling and Tabu-search algorithm. Proc Inst Mech Eng Part B: J Eng Manuf 225(10):1825–1834

Esme U, Sagbas A, Kahraman F (2009) Prediction of surface roughness in wire electrical discharge machining using design of experiments and neural networks. Iran J Sci Technol 33(B3):1

Sarkar S, Mitra S, Bhattacharyya B (2005) Parametric analysis and optimization of wire electrical discharge machining of γ-titanium aluminide alloy. J Mater Process Technol 159(3):286–294

Dey S, Chakraborty S (2015) Forward and reverse mapping for WEDM process using artificial neural networks. Decis Sci Lett 4(3):277–288

Prasad VK, Rajyalakshmi G, Ramaiah PV (2013) Simulation and Modeling of performance characteristic of Wire Cut EDM on Inconel825 using Multiple Regression and ANN. In: International Conference on Mathematical Computer Engineering-ICMCE, p 147

Markopoulos AP, Manolakos DE, Vaxevanidis NM (2008) Artificial neural network models for the prediction of surface roughness in electrical discharge machining. J Intell Manuf 19(3):283– 292

Chandramouli S, Eswaraiah K (2016) Modeling of electrical discharge machining of 17-4 PH steel using regression analysis and artificial neural network. Int J Appl Eng Res 11(6):4359– 4362

Khan MAR, Rahman M, Kadirgama K (2014) Neural network modeling and analysis for surface characteristics in electrical discharge machining. Procedia Eng 90:631–636

Kumar S, Batish A, Singh R, Singh T (2014) A hybrid Taguchi-artificial neural network approach to predict surface roughness during electric discharge machining of titanium alloys. J Mech Sci Technol 28(7):2831–2844

Pradhan MK, Biswas CK (2010) Neuro-fuzzy and neural network-based prediction of various responses in electrical discharge machining of AISI D2 steel. Int J Adv Manuf Technol 50(5-8):591–610

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Majumder, H., Maity, K.P. Predictive Analysis on Responses in WEDM of Titanium Grade 6 Using General Regression Neural Network (GRNN) and Multiple Regression Analysis (MRA). Silicon 10, 1763–1776 (2018). https://doi.org/10.1007/s12633-017-9667-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-017-9667-1