Abstract

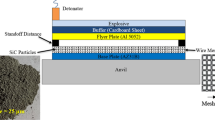

Industry X.0 is the new paradigm that is the driving phenomenon in the process of making things and the new method in which they are produced. In this work, we attempt to fabricate ceramic layer reinforced metal matrix composite (MMC) of AISI 316 L by a two-step laser process. The SiC-Ni-Ti layer on AISI316L serves to improve wear properties. The reinforcement of SiC-Ni-Ti on AISI316L modified the phase structure and microstructure. Coatings of metal-ceramic powders of 40 % SiC-40 %Ti-20 % Ni and 60 % SiC-30 %Ti-10 % Ni was preplaced on 316 L specimens. High power laser was used to irradiate the preplaced coatings to form MMCs of metal-ceramic particles. The composition of the MMC layer was studied by using optical emission spectroscopy (OES) and its microstructure of the MMC layers, phase analysis and its elemental analysis were characterized by optical and scanning electron microscopy (SEM), X-ray diffractometry, and image analyzing techniques, respectively. The formation of non-uniformity of coating thickness, microporous and crack formation at layer of MMC, revealed that a higher percentage of ceramic particles present in the MMC layer entails a particular disadvantage. The results confirmed the high hardness of the surface due to particle refinement with dispersion of hard SiC particle and precipitation of Cr2C3/Fe2Si in the matrix that results the improved wear resistance of laser clad material.

Similar content being viewed by others

Data Availability

The data used to support the findings of this study are included in the article.

Code Availability

Not applicable.

References

Sahasrabudhe H, Bose S, Bandyopadhyay A (2018) In: Jonathan L (ed) Advances in Laser Materials Processing, 2nd edn. Woodhead Publishing, Sawston, pp 507–539. https://doi.org/10.1016/B978-0-08-101252-9.00017-0

Wu CL, Zhang S, Zhang CH, Zhang JB, Liu Y, Chen J (2019) Opt Laser Technol 115:134–139. https://doi.org/10.1016/j.optlastec.2019.02.029

Guan D, He X, Zhang R, Li R, Qu X (2018) Vacuum 148:319–326. https://doi.org/10.1016/j.vacuum.2017.12.003

AlMangour B, Grzesiak D, Borkar T, Yang J-M (2018) Mater Des 138:119–128. https://doi.org/10.1016/j.matdes.2017.10.039

Ellis M, Xiao DC, Lee C, Steen WM, Watkins KG, Brown WP (1995) J Mater Process Technol 52:55–67. https://doi.org/10.1016/0924-0136(94)01443-5

Zhang Z, Yu T, Kovacevic R (2017) Appl Surf Sci 410:225–240. https://doi.org/10.1016/j.apsusc.2017.03.137

Kumar K, Zindani D, Paulo Davim J (2018) Advanced machining and manufacturing processes. Springer, Berlin. https://doi.org/10.1007/978-3-319-76075-9

Quiroz F, García-Castillo FA, Reyes-Osorio LA, Ávila-Cabrera A (2016) Finite Element Modeling of Friction Stir Spot Welding (FSSW) of Ti-6Al-4V. In: International Materials Research Congress. Springer, Cham, pp 119–128

Srivastava D, Chang ITH, Loretto MH (2001) Intermetallics 9:1003–1013. https://doi.org/10.1016/S0966-9795(01)00063-2

Dutta Majumdar J, Pinkerton A, Liu Z, Manna I, Li L (2005) Appl Surf Sci 247:320–327. https://doi.org/10.1016/j.apsusc.2005.01.039

Wang F, Mei J, Jiang H, Wu X (2007) Mater Sci Eng A 445–446:461–466. https://doi.org/10.1016/j.msea.2006.09.093

Li Q, Song GM, Zhang YZ, Lei TC, Chen WZ (2003) Wear 254:222–229. https://doi.org/10.1016/S0043-1648(03)00007-3

Vreeling JA, Ocelík V, De Hosson JTM (2002) Acta Mater 50:4913–4924. https://doi.org/10.1016/S1359-6454(02)00366-X

Majumdar J, Li L (2009) Metall Mater Trans A 40:3001–3008. https://doi.org/10.1007/s11661-009-0018-8

Chen T, Wu F, Wang H, Liu D (2018) Metals 8:601. https://doi.org/10.3390/met8080601

Sadeh S, Gleason GH, Hatamleh MI, Sunny SF, Yu H, Malik AS, Qian D (2019) Metals 9:1196. https://doi.org/10.3390/met9111196

Sano T, Eimura T, Hirose A, Kawahito Y, Katayama S, Arakawa K, Masaki K, Shiro A, Shobu T, Sano Y (2019) Metals 9:1192. https://doi.org/10.3390/met9111192

Troiani E, Zavatta N (2019) Metals 9:728. https://doi.org/10.3390/met9070728

Kallien Z, Keller S, Ventzke V, Kashaev N, Klusemann B (2019) Metals 9:655. https://doi.org/10.3390/met9060655

Li Z, Yu G, He X, Li S, Zhao Y (2018) Metals 8:799. https://doi.org/10.3390/met8100799

Hernando I, Arrizubieta JI, Lamikiz A, Ukar E (2018) Metals 8:536. https://doi.org/10.3390/met8070536

Wu J, Zhang H, Feng Y, Luo B (2018) Metals 8:443. https://doi.org/10.3390/met8060443

Bhowmik A, Dey D, Biswas A (2021) Silicon 13:2003–2010. https://doi.org/10.1007/s12633-020-00591-2

Dey D, Bhowmik A, Biswas A (2020) Effect of SiC content on mechanical and tribological properties of Al2024-SiC composites. Silicon. https://doi.org/10.1007/s12633-020-00757-y

Bhowmik A, Chakraborty D, Dey D, Biswas A (2020) Mater Today Proc 26:2992–2995. https://doi.org/10.1016/j.matpr.2020.02.617

Karamış MB, Erturun V, Sarı FN (2012) Investigation on effects of reciprocating extrusion process on microstructure of AA 6061 based composites. Mater Sci Technol 28:1379–1384. https://doi.org/10.1179/1743284712Y.0000000086

Acknowledgements

We would like to thank the Dr. Navalar Nedunchezhiyan College of Engineering, Cuddalore; Karpagam Academy of Higher Education, Coimbatore; Anna University, Regional Campus Madurai for completing this research work.

Author information

Authors and Affiliations

Contributions

Conceptualization: C. Ramesh Kannan, S. Manivannan; Methodology: C. Ramesh Kannan, S. Manivannan; Formal analysis and investigation: C. Ramesh Kannan, B. Stalin, C. Kailasanathan; Writing - original draft preparation: C. Ramesh Kannan, S. Manivannan; Writing - review and editing: B. Stalin, C. Kailasanathan; Funding acquisition: C. Ramesh Kannan; Resources: S. Manivannan; Supervision: B. Stalin.

Corresponding author

Ethics declarations

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Conflict of Interest

The authors declare that they have no conflict of interest.

Ethics Approval and Consent to Participate

This chapter does not contain any studies with human participants or animals performed by any of the authors.

Consent for Publication

This manuscript does not contain data from any individual person. Not applicable.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kannan, C.R., Manivannan, S., Stalin, B. et al. Metallographic Characterization of SiC-Ni-Ti Layer Reinforced on Austenitic Stainless Steel (AISI 316L) by Two-step Laser Fabrication. Silicon 14, 5393–5400 (2022). https://doi.org/10.1007/s12633-021-01305-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12633-021-01305-y