Abstract

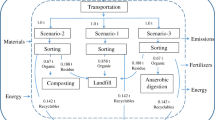

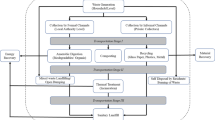

Landfilling and recycling, the predominant waste management methods in Thailand have been evaluated in a life cycle perspective using a case study in Nonthaburi municipality. The major focus was to identify the effects of the recycling activities on the sustainability of the existing waste management. A set of relevant indicators has been used to evaluate the ultimate damages/effects related to environmental, economic and social aspects of waste management methods, including valorisation. “Damage to ecosystems” and “damage to abiotic resources” were considered as the most relevant indicators to assess environmental sustainability. “Life cycle cost” was used as the economic indicator. “Damage to human health” and “income based community well-being” were considered as the most relevant indicators for social sustainability assessment. The results obtained showed that recycling contributes substantially to improving overall social, economic and environmental sustainability of the waste management system. In fact, the recycling of 24 % of Municipal Solid Waste (MSW) was found to compensate the negative environmental, economic and social impacts resulting from the landfilling of the remaining 76 % of MSW. Furthermore, the quantified results in relation to sustainability of recycling reflect the progress made in realizing the policy targets and policy effectiveness in Nonthaburi. Thus, the results of this study could be used to convince stakeholders involved in waste management about the overall benefits of recycling and its influences on sustainability for promoting and strengthening recycling activities in Thailand.

Similar content being viewed by others

References

Nithikul, J., Karthikeyan, O.P., Visvanathan, C.: Reject management from a mechanical biological treatment plant in Bangkok. Thailand. Resour. Conserv. Recy. 55(4), 417–422 (2010)

PCD.: State of Municipal Solid Waste. The Pollution Control Department, Thailand. http://www.pcd.go.th/(2009). Accessed 15 June 2010

Chiemchaisri, C., Juanga, J.P., Visvanathan, C.: Municipal solid waste management in Thailand and disposal emission inventory. Environ. Monit. Assess. 35, 13–20 (2007)

Nonthaburi Municipality: Sustainable Environmental Management in Nonthaburi. Nonthaburi Municipality. Bangkrasor, Thailand (2009)

Agarwal, A., Singhmar, A., Kulshrestha, M., Mittal, A.K.: Municipal solid waste recycling and associated markets in Delhi. India. Resour. Conserv. Recy. 44, 73–90 (2005)

Nonthaburi Municipality.: Nonthaburi Municipality. Bangkrasor, Thailand11000 (Personal communication) (2010)

Finnveden, G., Hauschild, M.Z., Ekvall, T., Guinée, J., Heijungs, R., Hellweg, S., Koehler, A., Pennington, D., Suh, S.: Recent developments in life cycle assessment. J. Environ. Manage. 91, 1–21 (2009)

Eriksson, O., Baky, A.: Identification and testing of potential key parameters in system analysis of municipal solid waste management. Resour. Conserv. Recy. 54, 1095–1099 (2010)

CALCAS—Co-ordination Action for innovation in Life-Cycle Analysis for Sustainability.: http://www.calcasproject.net (2011). Accessed 25 January 2011

IPCC.: In: Metz B., Davidson O.R., Bosch P.R., Dave R., Meyer L.A. (eds) Contribution of Working Group III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge University Press, Cambridge (2007)

Singh, R.K., Murty, H.R., Gupta, S.K., Dikshite, A.K.: An overview of sustainability assessment methodologies. Ecol. Indic. 9, 189–212 (2009)

Liamsanguan, C., Gheewala, S.H.: The holistic impact of integrated solid waste management on greenhouse gas emissions in Phuket. J. Cleaner Prod. 16, 1865–1871 (2008)

Cleary, J.: Life cycle assessments of municipal solid waste management systems: a comparative analysis of selected peer-reviewed literature. Environ. Inter. 35(8), 1256–1266 (2009)

Jeswani, H.K., Azapagic, A., Schepelmann, P., Ritthoff, M.: Options for broadening and deepening the LCA approaches. J. Cleaner Prod. 18, 120–127 (2010)

Cifrian, E., Coz, A., Viguri, J., Andrés, A.: Indicators for valorisation of municipal solid waste and special waste. Waste Biomass Valor. 1, 479–486 (2010)

Pré Consultants.: The Eco-indicator 99—A Damage Oriented Method for Life Cycle Assessment. Methodology Report, The Netherlands. http://www.pre.nl/(2001). Accessed 30 December 2008

Goedkoop, M.J., Heijungs, R., Huijbregts, M., De Schryver, A., Struijs, J., Van Zelm R.: ReCiPe-2008—A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level. First edition Report I: Characterization. http://www.lciarecipe.net (2009). Accessed 25 May 2010

Scotti, M., Bondavalli, C., Bodini, A.: Ecological footprint as a tool for local sustainability: the municipality of Piacenza (Italy) as a case study. Environ. Impact Assess. Rev. 29, 39–50 (2009)

Schaefer, F., Luksch, U., Steinbach, N., Cabeça, J., Hanauer, J.: Ecological Footprint and Biocapacity. Office for Official Publications of the European Communities. ISBN 92-79-02943-6 (2006)

Huijbregts, M.A.J., Hellweg, S., Frischknecht, R., Hungerbühler, K., Hendriks, A.J.: Ecological footprint accounting in the life cycle assessment of products. Ecol. Econ. 64, 798–807 (2008)

Wackernagel, M., Monfreda, C., Moran, D., Wermer, P., Goldfinger, S., Deumling, D., Murray, M.: National Footprint and Biocapacity Accounts 2005: The Underlying Calculation Method. Global Footprint Network, Oakland (2005)

Omer, A.M.: Energy, environment and sustainable development. Renew. Sustain. Energy Rev. 12, 2265–2300 (2008)

Wang, Y.: Fiber and textile waste utilization. Waste Biomass Valor 1, 135–143 (2010)

CIA.: The World Fact Book. The US Central Intelligence Agency. https://www.cia.gov/library/publications/the-world-factbook/geos/sw.html (2008). Accessed 25 March 2010

Reich, M.C.: Economic assessment of municipal waste management systems—case studies using a combination of life cycle assessment (LCA) and life cycle costing (LCC). J. Cleaner Prod. 13, 253–263 (2005)

Ngoc, U.N., Schnitzer, H.: Sustainable solutions for solid waste management in Southeast Asian countries. Waste Manage. 29, 1982–1995 (2009)

Lutz, J., Lekov, A., Chan, P., Whitehead, C.D., Meyers, S., McMahon, J.: Life-cycle cost analysis of energy efficiency design options for residential furnaces and boilers. Energy 31, 311–329 (2006)

Utne, I.B.: Life cycle cost (LCC) as a tool for improving sustainability in the Norwegian fishing fleet. J. Cleaner Prod. 17, 335–344 (2009)

Steen, B.: A systematic approach to environmental priority strategies in product development (EPS) version 2000—models and data of the default method, CPM report 1999. Chalmers University of Technology, Environmental Systems Analysis (2000)

Nguyen, T.L.T., Gheewala, S.H.: Fuel ethanol from cane molasses in Thailand: environmental and cost performance. Energy Policy 36, 1589–1599 (2008)

Giusti, L.: A review of waste management practices and their impact on human health. Waste Manage. 29, 2227–2239 (2009)

Pré Consultants.: BUWAL 250, SimaPro 7.1 manual. Amersfoort, Netherlands (2004)

Jørgensen, A., Bocq, A.L., Nazarkina, L., Hauschild, M.: Methodologies for social life cycle assessment. Int. J. Life Cycle Assess. 13(2), 96–103 (2008)

Hunkeler, D.: Societal LCA Methodology and Case Study. Int. J. Life Cycle Assess. 11(6), 371–382 (2006)

PCD.: Vehicle emission data, pollution control department, Thailand. Available http://infofile.pcd.go.th (2009) Accessed on 10 November 2010

Hischier, R., St. Gallen, E.M.P.A.: Ecoinvent. Life cycle inventories of packaging and graphical papers. Eco invent report no. 11, Swiss Centre for Life Cycle Inventories, Dübendorf (2007)

DEDE: Department of Alternative Energy Development and Efficiency.: Annual report, Ministry of Energy, Thailand (2008)

IPCC.: In: Eggleston H.S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K. (eds.) Guidelines for national greenhouse gas inventories, prepared by the National Greenhouse Gas Inventories Programme. Published: IGES, Japan (2006)

IAI.: IAI-International Aluminium Institute. Life cycle Assessment of Aluminium: Inventory Data for the Primary Aluminium Industry. http://www.world-aluminium.org/About+Aluminium/Story+of (2007). Accessed 5 August 2010

EAA (European Aluminium Association).: Environmental Profile Report for the European Aluminium Industry. http://www.eaa.net/upl/4/en/doc/EAA_Environmental_profile_report_May08.pdf (2008). Accessed 15 August 2010

Oers, L., Koning, A., Jeroen, G.: Abiotic Resource Depletion in LCA. Road and Hydraulic Engineering Institute, Leiden (2002)

Acknowledgments

Research grant from the Joint Graduate School of Energy and Environment is acknowledged. The authors would like to thank Nonthaburi Municipal Council, sorting and recycling facilities in Thailand for providing required data.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Midpoint Impact Categories Related to MSW Management

Resources consumption (inputs) and emissions(outputs)/from MSW management | Midpoint impacts | Unit of measurement | General formula to quantify the magnitude of impacts | References for background information |

|---|---|---|---|---|

Input: Land consumption Land occupation and land transformation → treatment facilities, final disposal, transportation, fossil fuel mining for energy | Land occupation (LO)/(Ecological Footprint—EF) | m2 year | \( {\text{LO}}_{\text{direct(local)}} = \sum\limits_{\text{a}} {{\text{A}}_{\text{a}} \times {\text{t}}_{\text{a}} } \) where LODirect, direct land occupation; Aa, occupation of area by local land use type a, ta-occupation time (years) \( {\text{LO}}_{\text{Gross}} = {\text{LO}}_{\text{EM}} + {\text{LO}}_{\text{T}} + {\text{LO}}_{\text{TF}} \quad {\text{LO}}_{\text{Net}} = {\text{LO}}_{\text{Gross}} - {\text{LO}}_{\text{P}} \) where LOEM, T,TF,P, land occupation for energy and material production, transportation, treatment facility, by-products | [21, 41] |

Input: Fossil fuel and mineral consumption Crude oil → diesel production for transportation, waste handling and processing machineries Coal, natural gas, crude oil → electricity and thermal energy required for recycling, operating machineries | Abiotic resource depletion potential | kg Sb eq. | \( {\text{AR}}_{\text{Gross(i)}} = {\text{AR}}_{\text{EM(i)}} + {\text{AR}}_{\text{T(i)}} + {\text{AR}}_{\text{TF(i)}} \quad {\text{AR}}_{\text{Net(i)}} = {\text{ARD}}_{\text{Gross(i)}} - {\text{AR}}_{\text{REM(i)}} = {\text{m}}_{\text{i}} \) where ARGross(i), gross abiotic resource i, AR REM(i) is abiotic resources i conservation from Recovered Energy and Materials. mi, net quantity of resource i extracted \( {\text{ADP}}_{\text{i}} = \frac{{{\text{DR}}_{\text{i}} }}{{\left( {{\text{R}}_{\text{i}} } \right)^{2} }} \times \frac{{({\text{R}}_{\text{ref}} )^{2} }}{{{\text{DR}}_{\text{ref}} }} \) where ADPi, abiotic depletion potential of resource i; Ri, ultimate reserve of resources i (kg); DRi, extraction rate of resources i (kg year−1); Rref, ultimate reserve of the reference resource (antimony kg); DRref, extraction rate of the reference resource (kg year−1) \( {\text{ADP}} = \sum\limits_{i} {{\text{ADP}}_{i} } \times {\text{m}}_{\text{i}} \) | [41] |

Outputs: Emissions NH3, NO2 −, NO3 −, PO −34 → landfill/open dumps, anaerobic digestion NOx → transportation, energy and auxiliary materials production, incineration, NH3, H2S → landfills/open dumps, anaerobic digestion, NOx, SOx → fuel production, incinération transportation HCl, HF → fuel production | Eutrophication potential | kg PO4 3− eq. or kg NO3 −eq | \( {\text{X}}_{\text{Gross}} = \sum {\left( {{\text{Q}}_{\text{i}} {\text{EM}} \times {\text{EF}}_{\text{i}} } \right)} + \sum {\left( {{\text{Q}}_{\text{i}} {\text{T}} \times {\text{EF}}_{i} } \right)} + \sum {\left( {{\text{Q}}_{\text{i}} {\text{TF}} \times {\text{EF}}_{\text{i}} } \right)} \) \( {\text{X}}_{\text{Net}} = {\text{X}}_{\text{Gross}} - \sum {({\text{Q}}_{\text{i}} {\text{PA}} \times {\text{EF}}_{\text{i}} )} \) Here X = GWP, POFP, EP, AP, HTP GWP, global warming potential; POFP, photo-oxidant formation potential; EP, eutrophication potential; AP, acidification potential; HTP, human toxicity potential; Qi, magnitude of substance i from EM—energy and material production; T, transportation; TF, treatment facility; PA, potential avoidance; EFi, equivalency factor of ith substance | |

Acidification potential | kg SO2 eq. | |||

VOCs, NH3 → landfill/open dumps, anaerobic digestion, composting, NOx, SOx, PM10 → Transportation, energy and auxiliary materials production, incineration, | Human toxicity potential | kg 1–4 DB eq | ||

VOCs → landfill/open dumps, anaerobic digestion, aerobic composting, CO, NOx → transportation, energy and auxiliary materials production, incineration, | Photo oxidant formation potential | kg C2H4 eq. | ||

CH4 → landfill/open dumps CO2, N2O, CO → transportation of MSW, energy and auxiliary material production, incineration | Global warming potential | kg CO2 eq. |

Appendix 2: Life Cycle Inventory of Recycling, Production of an Equal Amount of Materials via Virgin Production and Landfilling

Paper recycling | Plastics recycling | Aluminium recycling | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

Inputs/outputs | Units | 1 tonne of paper waste recycling | Virgin production of 893 kg paper | Inputs/outputs | Units | 1 tonne of plastic waste recycling | Virgin production of 900 kg plastics | Inputs/outputs | Units | 1 tonne of aluminium waste recycling | Virgin production of 758 kg Aluminium |

Raw materials/energy consumption | Raw materials/energy consumption | Raw materials/energy consumption | |||||||||

Hard Wood | m3 | 0.00E+00 | 6.96E−02 | Hard coal | kg | 4.25E−02 | 1.03E+02 | Total scrap input | kg | 1.00E+03 | 0.00E+00 |

Soft wood | m3 | 0.00E+00 | 1.97E+00 | Soft coal | kg | 7.45E+02 | 1.51E+01 | Bauxite | kg | 1.40E−02 | 3.99E+03 |

Wood chips | m3 | 0.00E+00 | 7.50E−02 | Heavy oil | kg | 8.69E+00 | 8.24E+02 | Alumina input | kg | 0.00E+00 | 1.46E+03 |

Sulphate pulp | kg | 0.00E+00 | 6.99E+01 | Natural gas | m3 | 6.55E+02 | 6.25E+02 | Anodes | kg | 0.00E+00 | 3.29E+02 |

Mixed waste paper | kg | 9.76E+02 | 1.81E+02 | Aluminium, | kg | 0.00E+00 | 1.51E−01 | Aluminium | kg | 0.00E+00 | 7.58E+02 |

Kaolin | kg | 5.76E+01 | 8.03E+01 | Iron, 46 % in ore | kg | 9.75E−03 | 2.63E+00 | Electricity | kWh | 9.65E+01 | 1.19E+04 |

Aluminium | kg | 9.22E+00 | 6.51E+00 | Emissions | Hard coal | kg | 6.06E+01 | 2.40E+03 | |||

Electricity | kWh | 4.70E+02 | 1.12E+03 | CO2 | kg | 2.14E+03 | 1.58E+03 | Soft coal | kg | 1.90E+01 | 2.57E+03 |

Hard coal | kg | 3.35E+02 | 9.13E+01 | CO | kg | 1.85E+00 | 7.56E+00 | Heavy oil | kg | 5.63E+01 | 2.10E+02 |

Soft coal | kg | 9.27E+01 | 2.46E+02 | CH4 | kg | 1.71E−02 | 1.25E+01 | Natural gas | m3 | 1.67E+01 | 6.08E+02 |

Heavy oil | kg | 1.51E+01 | 2.83E+01 | NOx | kg | 6.76E+00 | 4.01E+00 | Emissions | |||

Natural gas | m3 | 8.30E+01 | 1.95E+02 | SOx | kg | 9.05E+00 | 4.19E+00 | CO2 | kg | 3.91E+02 | 1.24E+04 |

Emissions | NMVOC | kg | 1.48E−01 | 3.64E+00 | CO | kg | 3.11E−01 | 1.64E+01 | |||

CO2 | kg | 1.25E+03 | 9.61E+02 | PM > 10 mm | kg | 2.06E+00 | 6.68E−01 | CH4 | kg | 3.23E−02 | 1.27E+00 |

CO | kg | 1.66E+00 | 1.94E+00 | HCl | kg | 4.66E−06 | 5.50E−02 | N2O | kg | 1.69E−05 | 0.00E+00 |

CH4 | kg | 1.94E−01 | 2.56E−01 | NH3 | kg | 8.91E−05 | 0.00E+00 | ||||

N2O | kg | 8.63E−03 | 2.37E−04 | NOx | kg | 6.90E−01 | 4.19E+01 | ||||

NH3 | kg | 4.68E−04 | 1.26E−03 | SOx | kg | 3.45E−01 | 5.43E+01 | ||||

NOx | kg | 3.23E+00 | 3.28E+00 | NMVOCs | kg | 3.76E−02 | 7.73E−02 | ||||

SOx | kg | 1.26E+00 | 2.80E+00 | PM > 10 mm | kg | 1.53E−01 | 1.09E+01 | ||||

NMVOCs | kg | 1.95E−01 | 4.91E−01 | HF | kg | 0.00E+00 | 4.22E−01 | ||||

PM > 10 mm | kg | 8.48E−01 | 9.27E−01 | ||||||||

Metal recycling | Glass recycling | Existing landfilling | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Inputs/outputs | Units | 1 tonne of metal waste recycling | Virgin production of 900 kg metals | Inputs/outputs | Units | 1 tonne of glass waste recycling | Virgin production of 950 kg glass | Inputs/outputs | Units | Landfilling of 1 tonne of waste |

Raw materials/energy consumption | Raw materials/energy consumption | Raw materials/energy consumption | ||||||||

Limestone | kg | 0.00E+00 | 2.57E+02 | Recycling glass | kg | 1.00E+03 | 1.96E+01 | Bauxite | kg | 5.69E−02 |

Iron, 46 % in ore | kg | 0.00E+00 | 2.18E+03 | Dolomite | kg | 0.00E+00 | 1.85E+02 | Iron | kg | 2.97E−02 |

Scrap, external | kg | 1.07E+03 | 1.10E+02 | Iron ore | kg | 0.00E+00 | 1.12E−02 | Hard coal | kg | 1.37E−01 |

Hard coal | kg | 1.65E+02 | 1.07E+03 | Limestone | kg | 5.10E+00 | 2.40E+02 | Soft coal | kg | 1.07E−01 |

Soft coal | kg | 2.54E+02 | 9.60E+01 | Sand, quartz | kg | 0.00E+00 | 5.83E+02 | Heavy oil | kg | 7.14E+00 |

Heavy oil | kg | 2.23E+01 | 7.97E+01 | Sodium chloride | kg | 6.39E+00 | 2.31E+02 | Emissions | ||

Natural gas | m3 | 1.15E+02 | 1.18E+02 | Hard coal | kg | 1.15E+01 | 9.60E+01 | CO2 | kg | 2.65E+01 |

Emissions | Soft coal | kg | 7.93E+00 | 1.92E+01 | CO | kg | 3.85E−01 | |||

CO2 | kg | 1.05E+03 | 2.69E+03 | Heavy oil | kg | 1.60E+02 | 2.06E+02 | CH4 | kg | 3.50E+01 |

CO | kg | 4.16E+00 | 1.67E+01 | Natural gas | m3 | 2.34E+01 | −3.02E+00 | N2O | kg | 7.10E−05 |

CH4 | kg | 1.83E+00 | 9.77E+00 | Emissions | NH3 | kg | 1.02E+01 | |||

N2O | kg | 5.34E−03 | 8.69E−03 | CO2 | kg | 5.51E+02 | 1.00E+03 | NOx | kg | 2.55E−01 |

NH3 | kg | 1.69E−03 | 1.78E−03 | CO | kg | 2.54E−01 | 1.49E+00 | SOx | kg | 2.48E−02 |

NOx | kg | 2.43E+00 | 4.12E+00 | CH4 | kg | 7.42E−01 | 7.86E−01 | H2S | kg | 4.47E−01 |

SOx | kg | 2.64E+00 | 5.64E+00 | N2O | kg | 1.60E−03 | 2.49E−03 | NMVOCs | kg | 1.48E−01 |

H2S | kg | 0.00E+00 | 8.96E−03 | NH3 | kg | 2.49E−03 | 8.44E−02 | PM > 10 mm | kg | 6.08E−02 |

NMVOCs | kg | 4.09E−01 | 9.14E−01 | NOx | kg | 2.89E+00 | 1.04E+00 | NO3 − | kg | 9.01E−01 |

PM > 10 mm | kg | 1.06E+00 | 1.28E+00 | SOx | kg | 7.09E−01 | 4.26E+00 | |||

HF | kg | 1.37E−02 | 9.96E−03 | NMVOCs | kg | 1.30E+00 | 2.00E+00 | |||

HCl | kg | 1.20E−01 | 7.81E−02 | PM > 10 mm | kg | 6.74E−01 | 1.84E+00 | |||

HF | kg | 2.23E−02 | 3.12E−03 | |||||||

HCl | kg | 5.58E−02 | 1.12E−01 | |||||||

Appendix 3: Quantification of Ultimate Damages for Recycling of One tonne of Paper Waste

(a) Quantification of “damage to ecosystem” from paper recycling (this table shows only the gross damage calculation from paper recycling. Similar approach was followed to quantify gross damage from the virgin production process)

Concept/mathematical formula used | Magnitude | Description/background information | |||

|---|---|---|---|---|---|

1. Ecosystem damage from acidifying/eutrophying substances | |||||

Acidifying/eutrophying substances | NH3 | NOx | SOx | ||

Emission per tonne of waste paper recycling (kg) | (mi) | 4.68E−04 | 3.23E+00 | 1.26E+00 | Data from inventory analysis |

Damage factor \( ( {\text{PDF}}\,{\text{m}}_{\text{local}}^{2} \,{\text{year}}) \)/kg of substance | (αi) | 15.57 | 5.713 | 1.041 | [16] |

Damage to ecosystem from each substance\( ({\text{PDF}}\,{\text{m}}_{\text{local}}^{2} \,{\text{year}}) \)/tonne of waste paper | \( {\text{DE}}_{\text{local}} = {\text{m}}_{\text{i}} \times \alpha_{\text{i}} \) | 7.29E−03 | 1.84E+01 | 1.32E+00 | [16] |

Total damage to ecosystem from all the acidifying/eutrophying substances \( (PDF.m_{local}^{2} .yr) \)/tonne of waste paper | \( {\text{DE}}_{\text{local}} = \sum\limits_{\text{i}} {{\text{m}}_{\text{i}} \alpha_{\text{i}} } \) | 1.98E+01 | [16] | ||

Equivalency factor (EF) for marginal cropland (global m2) (assuming the effects may occur at cropland) | Equivalency factor (global m2/m2) | 1.8 | |||

Yield factor for marginal cropland | Yield factor (dimensionless) | 2 | |||

Damage to ecosystem at global scale due to acidifying/eutrophying substances (PDF global m2 year)/tonne of waste paper | DEglobal = DElocal × equivalency factor (global ha/ha) × yield factor | 7.12E+01 | Authors derived formula | ||

2. Ecosystem damage due to direct and indirect land occupation/conversion | |||||

Damage to ecosystem (local) due to direct land occupation for recycling of paper\( ({\text{PDF}}\,{\text{m}}_{\text{local}}^{2} \,{\text{year}}) \)/tonne of waste paper | DElocal = PDF × Area × time (direct land occupation for paper recycling is assumed to be negligible. Thus Area = 0) | 0E+00 | [16] | ||

Damage to ecosystem due to direct land occupation for recycling of paper (PDF global m2 year)/tonne of waste paper | DEglobal = DElocal × equivalency factor (global ha/ha) × Yield factor | 0E+00 | Authors derived formula | ||

Total fossil energy consumption for recycling (MJ/tonne of waste paper) (including energy for transportation, thermal energy and electricity) | Total energy consumed (MJ) = transportation + heat + electricity | 1.32E+04 | Authors derived formula | ||

Land occupation for fossil energy generation (global m2 year/MJ) | Characterization factor (global m2 year/MJ) | 0.5 | [20] | ||

Land occupation for fossil energy generation (global m2 year/tonne of waste paper) | Land occupation(global) = total energy (MJ) × characterization factor (global m2 year/MJ) | 6.62E+03 | [16] | ||

PDF of fossil fuel mining land | PDF (dimensionless) | 1.19 | [17] | ||

Yield factor for mining land | Yield factor (dimensionless) | 2 | |||

Damage to ecosystem due to fossil energy consumption (PDF global m2 year)/tonne of waste paper | DEglobal = land occupation(global) × PDF × yield factor | 1.58E+04 | |||

Gross ecosystem damage (PDF global m 2 year) from recycling of one tonne of waste paper | Gross ecosystem damage = DE acidification/eutrophication + DE occupatiom | 1.58E+04 | |||

(b) Quantification of “damage to abiotic resources” from recycling

Calculation of damage to reference resources (Dr) (Reference resource—crude oil 42 MJ/kga)

Description | Value | Unit |

|---|---|---|

(a) Volume of one oil barrel in liters | 160 | L |

(b) Estimated extraction cost incrementa | 30 | $/barrel in year 2000 |

(c) Mass of oil in one barrel | 136 | kg |

(d) Extraction cost increment per kg oil extraction (d) = (b)/(c) | 0.22 | $/kg (relative to year 2000) |

(e) Production amount in base year 2000 (based on ReCiPe Model)a | 3.43E+12 | kg |

(f) Marginal Cost Increase (MCIr)a (f) = (d)/(e) | 6.43E−14 | $/kg/kg |

(g) Average inflation rate of Middle East countries (d)b | 5 | % |

(h) Time period between current year and the base year (t)a | 10 | From base year (2000 to 2010) |

(i) Future value of 1 dollar for year 2010 (1 + d)t (i) = (1 + (g)/100)h | 1.63 | $ (relative to base year 2000) |

(j) Damage of 1 kg of crude oil extraction (Dr) (j) = (e) × ((f) × (i) | 0.36 | $/kg (year 2010) |

Calculation of “damage to abiotic resources” from paper recycling (similar approach was followed to calculate damage from the virgin production process)

Type of fossil fuel used | ||||

|---|---|---|---|---|

Description | Hard coal (18 MJ/kg) | Soft coal (10 MJ/kg) | Heavy oil (42 MJ/kg) | Natural gas (36.6 kg/m3) |

Amount of fossil energy used (kg/tonne of paper waste)* | 335 | 92.7 | 15.1 | 83 |

Characterization factors (relative to the energy content of crude oil 42 MJ/kg)a | 0.43 | 0.24 | 1.00 | 0.87 |

Fossil fuel consumption (kg crude oil-eq)/tonne of paper waste | 143.57 | 22.07 | 15.10 | 72.33 |

Total fossil fuel consumption (kg crude oil-eq/tonne of paper waste) | 253.07 | |||

Damage of 1 kg of crude oil (reference resource) extraction ($/kg) | 0.36 | |||

Gross damage to abiotic resources from recycling ($/tonne of paper waste) | 91.11 | |||

(c) Calculation of “Life Cycle Cost” of paper recycling

Description | Value | Unit |

|---|---|---|

(a) Capital Cost | 85 (3)* | Baht/tonne of paper waste |

(b) Operational and maintenance costs | 18,457 (599) | Baht/tonne of paper waste |

(c) Environmental cost | 2,833 (92) | Baht/tonne of paper waste |

(d) Gross life cycle cost of paper recycling (d) = (a) + (b) + (c) | 21,374 (694) | Baht/tonne of paper waste |

Revenue generation | ||

(e)Average selling prices of the recycled paper | 22,400 (727) | Baht/tonne of recycled paper |

(f) Recyclability of paper waste | 0.91 | Tonne of recycled paper/tonne of paper waste |

(g) Income generation potential by selling recycled paper (g) = (e) × (f) | 20,384 (662) | Baht/tonne of paper waste |

(h) Credited environmental cost | 3,045 (99) | Baht/tonne of paper waste |

(i) Total revenue generation (i) = (g) + (h) | 23,429 (761) | Baht/tonne of paper waste |

(j) Net life cycle cost (j) = (d) − (i) | −2,055 (−67) | Baht/tonne of paper waste |

(d) Calculation of “damage to human health” from paper recycling (similar approach was followed to calculate damage from the virgin production process)

(a) Type of emissions* | (b) Magnitude of emissions from paper recycling (kg/tonne of paper waste)* | Characterization factorsa | (f) Total health damage (DALYs/tonne of paper waste) (f) = (b) × (c) + (b) × (d) + (b) × (e) | ||

|---|---|---|---|---|---|

(c) Mortality occurrence (YOLL/kg of pollutant) | (d) Severe morbidity(person years YLD/kg of pollutant) | (e) Morbidity (persons years YLD/kg of pollutant) | |||

CO2 | 1.25E+03 | 7.93E−07 | 3.53E−07 | 6.55E−07 | 2.26E−03 |

CO | 1.66E+00 | 2.38E−06 | 1.06E−06 | 1.96E−06 | 8.94E−06 |

CH4 | 1.94E−01 | 1.95E−05 | 8.65E−06 | 1.60E−05 | 8.55E−06 |

N2O | 8.63E−03 | 2.87E−04 | 1.10E−04 | 2.14E−04 | 5.27E−06 |

NH3 | 4.68E−04 | 2.64E−05 | −4.66E−06 | 7.22E−06 | 1.36E−08 |

NOx | 3.23E+00 | 2.45E−05 | −2.06E−06 | 3.61E−06 | 8.41E−05 |

SOx | 1.26E+00 | 3.76E−05 | −6.58E−06 | 1.02E−05 | 5.21E−05 |

NMVOCs | 1.95E−01 | 1.53E−05 | 4.25E−06 | 0.00E+00 | 3.83E−06 |

PM > 10 mm | 8.48E−01 | 4.24E−04 | −2.33E−06 | 3.61E−06 | 3.61E−04 |

Total health damage (DALYs/tonne of paper waste recycling (∑f) | 2.78E−03 | ||||

(e) Calculation of “Income based community well-being” from paper recycling

Description | Amount | Unit |

|---|---|---|

Income generation from selling of paper wastea | 4376.54 | Baht/tonne of paper waste |

Total created employment opportunities throughout the recycling process chainb | 0.71 | Labour days/tonne |

Wages based income generationc | 1,797.88 | Baht/tonne of paper waste |

Total income generation potential to the community | 6,174.43 | Baht/tonne of paper waste |

Per capita living expenses of middle-class people in Thailand | 5,000 | Baht/person/month |

No of individual who may deserve a better lifestyle due to this income increment in the society | ≥1 | No of individuals/tonne of paper waste recycling |

Rights and permissions

About this article

Cite this article

Menikpura, S.N.M., Gheewala, S.H., Bonnet, S. et al. Evaluation of the Effect of Recycling on Sustainability of Municipal Solid Waste Management in Thailand. Waste Biomass Valor 4, 237–257 (2013). https://doi.org/10.1007/s12649-012-9119-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-012-9119-5