Abstract

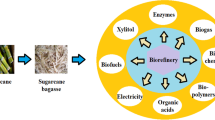

Sugarcane is among the leading agricultural crop cultivated in tropical regions of the world. Industrial processing of sugarcane generates sugar; as well as various solid wastes (i.e. sugarcane bagasse, pressmud). Improvement of biotechnology in industrial level, offers opportunities for economic utilization of these solid residues. In the last few decades, sugarcane bagasse and pressmud have been explored in the theme of lignocellulosic bioconversion. The recalcitrance of biomass is a major drawback towards successful exploitation of lignocellulosic residues. Pretreatment by suitable/efficient processes can overcome this limitation. In this regards; physical, chemical and biological treatment systems are brought into our perspective. Chemical and physicochemical methods are capital-intensive but not environment-friendly, in contrast, method like biological treatment is eco-friendly but extremely slow. There are still major technological and economic challenges need to be addressed; e.g. bioprospecting, established more reliable genetically modified microorganisms, upgrade gene cloning and sequencing processes, yield improvement at large scale etc. Productions of value-added products from these solid wastes are discussed in such a way that pinpoints the most recent trends and the future directions. Biofuels, enzymes, organic acids and bio-sorbents production draw a clear sketch of the current and future bio-based products. Nano-biotechnology and genetic engineering could be future trends to improved processes and products. This review serves as a valuable reference material for a wide range of scientists and technologists in the relevant fields.

Similar content being viewed by others

References

Chandel, A.K., Singh, O.V.: Weedy lignocellulosic feedstock and microbial metabolic engineering: advancing the generation of “Biofuel”. Appl. Microbiol. Biotechnol. 89(5), 1289–1303 (2011)

Somerville, C., Youngs, H., Taylor, C., Davis, S.C., Long, S.P.: Feedstocks for lignocellulosic biofuels. Science 329(5993), 790–792 (2010)

Pandey, A., Soccol, C.R., Nigam, P., Soccol, V.T.: Biotechnological potential of agro-industrial residues. I: sugarcane bagasse. Bioresour. Technol. 74(1), 69–80 (2000)

Chandel, A.K., da Silva, S.S., Carvalho, W., Singh, O.V.: Sugarcane bagasse and leaves: foreseeable biomass of biofuel and bio-products. J. Chem. Technol. Biotechnol. 87(1), 11–20 (2012)

Martín, C., Galbe, M., Nilvebrant, N.-O., Jönsson, L.J.: Comparison of the fermentability of enzymatic hydrolyzates of sugarcane bagasse pretreated by steam explosion using different impregnating agents. Appl. Biochem. Biotechnol. 98(1–9), 699–716 (2002)

Maitan-Alfenas, G.P., Visser, E.M., Guimarães, V.M.: Enzymatic hydrolysis of lignocellulosic biomass: converting food waste in valuable products. Curr. Opin. Food Sci. 1, 44–49 (2015)

Bhatnagar, A., Kesari, K.K., Shurpali, N.: Multidisciplinary approaches to handling wastes in sugar industries. Water Air Soil Pollut. 227(1), 1–30 (2016)

Balakrishnan, M., Batra, V.S.: Valorization of solid waste in sugar factories with possible applications in India: a review. J. Environ. Manage. 92(11), 2886–2891 (2011)

Solomon, S.: Sugarcane by-products based industries in India. Sugar Tech 13(4), 408–416 (2011)

Nava-Valente, N., Alvarado-Lassman, A., Nativitas-Sandoval, L.S., Mendez-Contreras, J.M.: Improved anaerobic digestion of a thermally pretreated mixture of physicochemical sludge; broiler excreta and sugar cane wastes (SCW): effect on organic matter solubilization, biodegradability and bioenergy production. J. Environ. Sci. Health A Tox. Hazard. Subst. Environ. Eng. 51(5), 446–453 (2016)

Liu, Y., Zhang, Y., Xu, J., Sun, Y., Yuan, Z., Xie, J.: Consolidated bioprocess for bioethanol production with alkali-pretreated sugarcane bagasse. Appl. Energy 157, 517–522 (2015)

Wei, D., Liu, X., Yang, S.-T.: Butyric acid production from sugarcane bagasse hydrolysate by Clostridium tyrobutyricum immobilized in a fibrous-bed bioreactor. Bioresour. Technol. 129, 553–560 (2013)

Veana, F., Martínez-Hernández, J.L., Aguilar, C.N., Rodríguez-Herrera, R., Michelena, G.: Utilization of molasses and sugar cane bagasse for production of fungal invertase in solid state fermentation using Aspergillus niger GH1. Braz. J. Microbiol. 45(2), 373–377 (2014)

Moubarik, A., Grimi, N.: Valorization of olive stone and sugar cane bagasse by-products as biosorbents for the removal of cadmium from aqueous solution. Food Res. Int. 73, 169–175 (2015)

Bhat, S.A., Singh, J., Vig, A.P.: Potential utilization of bagasse as feed material for earthworm Eisenia fetida and production of vermicompost. Springerplus 4(1), 11 (2015)

Mtui, G.Y.S.: Recent advances in pretreatment of lignocellulosic wastes and production of value added products. Afr. J. Biotechnol. 8(8), 1398–1415 (2009)

Canilha, L., Chandel, A.K., Suzane dos Santos Milessi, T., Antunes, F.A.F., Luiz da Costa Freitas, W., das Graças Almeida Felipe, M., da Silva, S.S.: Bioconversion of sugarcane biomass into ethanol: an overview about composition, pretreatment methods, detoxification of hydrolysates, enzymatic saccharification, and ethanol fermentation. BioMed Res. Int. 2012, 1–15 (2012)

Rubin, E.M.: Genomics of cellulosic biofuels. Nature 454(7206), 841–845 (2008)

Martin, C., Klinke, H.B., Thomsen, A.B.: Wet oxidation as a pretreatment method for enhancing the enzymatic convertibility of sugarcane bagasse. Enzyme Microb. Technol. 40(3), 426–432 (2007)

Zhao, X., Cheng, K., Liu, D.: Organosolv pretreatment of lignocellulosic biomass for enzymatic hydrolysis. Appl. Microbiol. Biotechnol. 82(5), 815–827 (2009)

Carvalheiro, F., Duarte, L.C., Gírio, F.M.: Hemicellulose biorefineries: a review on biomass pretreatments. J. Sci. Ind. Res. 67(11), 849–864 (2008)

Yang, B., Wyman, C.E.: Pretreatment: the key to unlocking low-cost cellulosic ethanol. Biofuels, Bioprod. Biorefin. 2(1), 26–40 (2008)

Galbe, M., Zacchi, G.: Pretreatment of lignocellulosic materials for efficient bioethanol production. Biofuels, pp. 41–65. Springer, Berlin (2007)

Ramadoss, G., Muthukumar, K.: Ultrasound assisted ammonia pretreatment of sugarcane bagasse for fermentable sugar production. Biochem. Eng. J. 83, 33–41 (2014)

da Silva, A.S.A., Inoue, H., Endo, T., Yano, S., Bon, E.P.S.: Milling pretreatment of sugarcane bagasse and straw for enzymatic hydrolysis and ethanol fermentation. Bioresour. Technol. 101(19), 7402–7409 (2010)

Buaban, B., Inoue, H., Yano, S., Tanapongpipat, S., Ruanglek, V., Champreda, V., Pichyangkura, R., Rengpipat, S., Eurwilaichitr, L.: Bioethanol production from ball milled bagasse using an on-site produced fungal enzyme cocktail and xylose-fermenting Pichia stipitis. J. Biosci. Bioeng. 110(1), 18–25 (2010)

Jiang, L., Zheng, A., Zhao, Z., He, F., Li, H.: Comprehensive utilization of glycerol from sugarcane bagasse pretreatment to fermentation. Bioresour. Technol. 196, 194–199 (2015)

Janke, L., Leite, A., Batista, K., Weinrich, S., Sträuber, H., Nikolausz, M., Nelles, M., Stinner, W.: Optimization of hydrolysis and volatile fatty acids production from sugarcane filter cake: Effects of urea supplementation and sodium hydroxide pretreatment. Bioresour. Technol. 199, 235–244 (2016)

Hernández-Salas, J.M., Villa-Ramírez, M.S., Veloz-Rendón, J.S., Rivera-Hernández, K.N., González-César, R.A., Plascencia-Espinosa, M.A., Trejo-Estrada, S.R.: Comparative hydrolysis and fermentation of sugarcane and agave bagasse. Bioresour. Technol. 100(3), 1238–1245 (2009)

Ramos, L.P., da Silva, L., Ballem, A.C., Pitarelo, A.P., Chiarello, L.M., Silveira, M.H.L.: Enzymatic hydrolysis of steam-exploded sugarcane bagasse using high total solids and low enzyme loadings. Bioresour. Technol. 175, 195–202 (2015)

González, L.M.L., Reyes, I.P., Dewulf, J., Budde, J., Heiermann, M., Vervaeren, H.: Effect of liquid hot water pre-treatment on sugarcane press mud methane yield. Bioresour. Technol. 169, 284–290 (2014)

Martin, C., Marcet, M., Thomsen, A.B.: Comparison between wet oxidation and steam explosion as pretreatment methods for enzymatic hydrolysis of sugarcane bagasse. BioResources 3(3), 670–683 (2008)

Camassola, M., Dillon, A.J.P.: Biological pretreatment of sugar cane bagasse for the production of cellulases and xylanases by Penicillium echinulatum. Ind. Crops Prod. 29(2), 642–647 (2009)

Contreras, A.M., Rosa, E., Perez, M., Van Langenhove, H., Dewulf, J.: Comparative life cycle assessment of four alternatives for using by-products of cane sugar production. J. Clean. Prod. 17(8), 772–779 (2009)

Cerqueira, D.A., Rodrigues Filho, G., da Silva Meireles, C.: Optimization of sugarcane bagasse cellulose acetylation. Carbohydr. Polym. 69(3), 579–582 (2007)

Paixão, S.M., Ladeira, S.A., Arez, B.F., Martins, M.L.L., Roseiro, J.C., Alves, L.M.: KOH for enhanced sugarcane bagasse delignification and further production of sugar-rich hydrolyzates by enzymes application. In: RRB’10—10th International Conference on Renewable Resources and Biorefineries, Valladolid, Spain, pp. 71–72 (2014)

Rezende, C.A., de Lima, M.A., Maziero, P., Ribeirode Azevedo, E., Garcia, W., Polikarpov, I.: Chemical and morphological characterization of sugarcane bagasse submitted to a delignification process for enhanced enzymatic digestibility. Biotechnol. Biofuels 4(1), 1 (2011)

Cheng, J., Zhu, M.: A novel anaerobic co-culture system for bio-hydrogen production from sugarcane bagasse. Bioresour. Technol. 144, 623–631 (2013)

Botha, T., Von Blottnitz, H.: A comparison of the environmental benefits of bagasse-derived electricity and fuel ethanol on a life-cycle basis. Energy Policy 34(17), 2654–2661 (2006)

Goh, C.S., Tan, K.T., Lee, K.T., Bhatia, S.: Bio-ethanol from lignocellulose: status, perspectives and challenges in Malaysia. Bioresour. Technol. 101(13), 4834–4841 (2010)

Mussatto, S.I., Dragone, G., Rocha, G.J.M., Roberto, I.S.C.: Optimum operating conditions for brewer’s spent grain soda pulping. Carbohydr. Polym. 64(1), 22–28 (2006)

Petit, A.: Application of vacuum belt press filters for cane mud filtration and performance comparison with rotary filters. Sugar Ind. Zuckerind. 139(5), 298–301 (2014)

Agrawal, K.M., Barve, B.R., Khan, S.S.: Biogas from press mud. J. Mech. Civil Eng. 37–41 (2010)

Cifuentes, R., de León, R., Porres, C., Rolz, C.: Windrow composting of waste sugar cane and press mud mixtures. Sugar Tech 15(4), 406–411 (2013)

Nyonje, E.O., Njogu, P., Kinyua, R.: Assessment of the potential for utilization of sugarcane derived press mud for biogas generation in South Nyanza sugarcane zones, Kenya. In: Proceedings of Sustainable Research and Innovation Conference, pp. 48–51 (2014)

Ansari, K.B., Gaikar, V.G.: Pressmud as an alternate resource for hydrocarbons and chemicals by thermal pyrolysis. Ind. Eng. Chem. Res. 53(5), 1878–1889 (2014)

Kumar, R., Kesavapillai, B.: Stimulation of extracellular invertase production from spent yeast when sugarcane pressmud used as substrate through solid state fermentation. Springerplus 1(1), 1–6 (2012)

López González, L.M., Reyes, I.P., Romero Romero, O., Budde, J.R., Heiermann, M., Vervaeren, H.: Antagonistic effects on the methane yield of liquid hot-water pretreated press mud fractions co-digested with vinasse. Energy Fuels 29(11), 7284–7289 (2015)

Sarker, T.C., Mannan, M.A., Sayeed, M.A., Alam, M.F.: Bioconversion of sugar cane industry by-product using bacterial strains. J. Chem. Phys. Biol. Sci. Sect. D 5(4), 4707–4717 (2015)

Partha, N., Sivasubramanian, V.: Recovery of chemicals from pressmud—a sugar industry waste. Indian Chem. Eng. 48(3), 160–163 (2006)

Kumar, P., Barrett, D.M., Delwiche, M.J., Stroeve, P.: Methods for pretreatment of lignocellulosic biomass for efficient hydrolysis and biofuel production. Ind. Eng. Chem. Res. 48(8), 3713–3729 (2009)

Taherzadeh, M.J., Karimi, K.: Pretreatment of lignocellulosic wastes to improve ethanol and biogas production: a review. Int. J. Mol. Sci. 9(9), 1621–1651 (2008)

Sun, Y., Cheng, J.: Hydrolysis of lignocellulosic materials for ethanol production: a review. Bioresour. Technol. 83(1), 1–11 (2002)

Hideno, A., Inoue, H., Tsukahara, K., Fujimoto, S., Minowa, T., Inoue, S., Endo, T., Sawayama, S.: Wet disk milling pretreatment without sulfuric acid for enzymatic hydrolysis of rice straw. Bioresour. Technol. 100(10), 2706–2711 (2009)

Sambusiti, C., Licari, A., Solhy, A., Aboulkas, A., Cacciaguerra, T., Barakat, A.: One-pot dry chemo-mechanical deconstruction for bioethanol production from sugarcane bagasse. Bioresour. Technol. 181, 200–206 (2015)

Zhu, S., Wu, Y., Yu, Z., Zhang, X., Li, H., Gao, M.: The effect of microwave irradiation on enzymatic hydrolysis of rice straw. Bioresour. Technol. 97(15), 1964–1968 (2006)

de Souza Moretti, M.M., Bocchini-Martins, D.A., Nunes, C.D.C.C., Villena, M.A., Perrone, O.M., da Silva, R., Boscolo, M., Gomes, E.: Pretreatment of sugarcane bagasse with microwaves irradiation and its effects on the structure and on enzymatic hydrolysis. Appl. Energy 122, 189–195 (2014)

Behera, S., Arora, R., Nandhagopal, N., Kumar, S.: Importance of chemical pretreatment for bioconversion of lignocellulosic biomass. Renew. Sustain. Energy Rev. 36, 91–106 (2014)

Sukumaran, R.K., Singhania, R.R., Mathew, G.M., Pandey, A.: Cellulase production using biomass feed stock and its application in lignocellulose saccharification for bio-ethanol production. Renew. Energy 34(2), 421–424 (2009)

Zhao, Y., Wang, Y., Zhu, J.Y., Ragauskas, A., Deng, Y.: Enhanced enzymatic hydrolysis of spruce by alkaline pretreatment at low temperature. Biotechnol. Bioeng. 99(6), 1320–1328 (2008)

Martín, C., Thomsen, A.B.: Wet oxidation pretreatment of lignocellulosic residues of sugarcane, rice, cassava and peanuts for ethanol production. J. Chem. Technol. Biotechnol. 82(2), 174–181 (2007)

Torre, P., Aliakbarian, B., Rivas, B., DomÃnguez, J.M., Converti, A.: Release of ferulic acid from corn cobs by alkaline hydrolysis. Biochem. Eng. J. 40(3), 500–506 (2008)

Kumari, S., Das, D.: Improvement of gaseous energy recovery from sugarcane bagasse by dark fermentation followed by biomethanation process. Bioresour. Technol. 194, 354–363 (2015)

Borges, E.R., Pereira Jr., N.: Succinic acid production from sugarcane bagasse hemicellulose hydrolysate by Actinobacillus succinogenes. J. Ind. Microbiol. Biotechnol. 38(8), 1001–1011 (2011)

Mosier, N., Wyman, C., Dale, B., Elander, R., Lee, Y.Y., Holtzapple, M., Ladisch, M.: Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour. Technol. 96(6), 673–686 (2005)

de Moraes Rocha, G.J., Martin, C., Soares, I.B., Maior, A.M.S., Baudel, H.M., De Abreu, C.A.M.: Dilute mixed-acid pretreatment of sugarcane bagasse for ethanol production. Biomass Bioenergy 35(1), 663–670 (2011)

Alvira, P., Tomás-Pejó, E., Ballesteros, M., Negro, M.J.: Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour. Technol. 101(13), 4851–4861 (2010)

Zhao, X., Peng, F., Cheng, K., Liu, D.: Enhancement of the enzymatic digestibility of sugarcane bagasse by alkali—peracetic acid pretreatment. Enzyme Microb. Technol. 44(1), 17–23 (2009)

Zhao, X., Wu, R., Liu, D.: Production of pulp, ethanol and lignin from sugarcane bagasse by alkali-peracetic acid delignification. Biomass Bioenergy 35(7), 2874–2882 (2011)

Hendriks, A., Zeeman, G.: Pretreatments to enhance the digestibility of lignocellulosic biomass. Bioresour. Technol. 100(1), 10–18 (2009)

Da Cruz, S.H., Dien, B.S., Nichols, N.N., Saha, B.C., Cotta, M.A.: Hydrothermal pretreatment of sugarcane bagasse using response surface methodology improves digestibility and ethanol production by SSF. J. Ind. Microbiol. Biotechnol. 39(3), 439–447 (2012)

Yu, Q., Zhuang, X., Wang, Q., Qi, W., Tan, X., Yuan, Z.: Hydrolysis of sweet sorghum bagasse and eucalyptus wood chips with liquid hot water. Bioresour. Technol. 116, 220–225 (2012)

Laser, M., Schulman, D., Allen, S.G., Lichwa, J., Antal, M.J., Lynd, L.R.: A comparison of liquid hot water and steam pretreatments of sugar cane bagasse for bioconversion to ethanol. Bioresour. Technol. 81(1), 33–44 (2002)

Gurgel, L.V.A., Pimenta, M.T.B., da Silva Curvelo, A.A.: Enhancing liquid hot water (LHW) pretreatment of sugarcane bagasse by high pressure carbon dioxide (HP-CO 2). Ind. Crops Prod. 57, 141–149 (2014)

McWilliams, R.C., Van Walsum, G.P.: Comparison of aspen wood hydrolysates produced by pretreatment with liquid hot water and carbonic acid. Biotechnology for fuels and chemicals, pp. 109–121. Springer, Berlin (2002)

Van Walsum, G. P. Severity function describing the hydrolysis of xylan using carbonic acid. In: Twenty-Second Symposium on Biotechnology for Fuels and Chemicals, Springer, pp. 317–329, (2001)

Yu, Q., Zhuang, X., Lv, S., He, M., Zhang, Y., Yuan, Z., Qi, W., Wang, Q., Wang, W., Tan, X.: Liquid hot water pretreatment of sugarcane bagasse and its comparison with chemical pretreatment methods for the sugar recovery and structural changes. Bioresour. Technol. 129, 592–598 (2013)

Yu, Q., Zhuang, X., Yuan, Z., Qi, W., Wang, W., Wang, Q., Tan, X.: Pretreatment of sugarcane bagasse with liquid hot water and aqueous ammonia. Bioresour. Technol. 144, 210–215 (2013)

van Walsum, G.P., Shi, H.: Carbonic acid enhancement of hydrolysis in aqueous pretreatment of corn stover. Bioresour. Technol. 93(3), 217–226 (2004)

Mosier, N., Hendrickson, R., Dreschel, R., Dien, B., Bothast, R., Welch, G., Ladisch, M: Principles and economics of pretreating cellulose in water for ethanol production. In: Proceedings of the 225th American Chemical Society Meeting, BIOT Division (2003)

Agbor, V.B., Cicek, N., Sparling, R., Berlin, A., Levin, D.B.: Biomass pretreatment: fundamentals toward application. Biotechnol. Adv. 29(6), 675–685 (2011)

Oliveira, F.M.V., Pinheiro, I.O., Souto-Maior, A.M., Martin, C., Gonçalves, A.R., Rocha, G.J.M.: Industrial-scale steam explosion pretreatment of sugarcane straw for enzymatic hydrolysis of cellulose for production of second generation ethanol and value-added products. Bioresour. Technol. 130, 168–173 (2013)

Geddes, C.C., Mullinnix, M.T., Nieves, I.U., Peterson, J.J., Hoffman, R.W., York, S.W., Yomano, L.P., Miller, E.N., Shanmugam, K.T., Ingram, L.O.: Simplified process for ethanol production from sugarcane bagasse using hydrolysate-resistant Escherichia coli strain MM160. Bioresour. Technol. 102(3), 2702–2711 (2011)

Rocha, G.J.M., Gonçalves, A.R., Oliveira, B.R., Olivares, E.G., Rossell, C.E.V.: Steam explosion pretreatment reproduction and alkaline delignification reactions performed on a pilot scale with sugarcane bagasse for bioethanol production. Ind. Crops Prod. 35(1), 274–279 (2012)

Rocha, G.J.M., Martín, C., da Silva, V.F.N., Gómez, E.O., Gonçalves, A.R.: Mass balance of pilot-scale pretreatment of sugarcane bagasse by steam explosion followed by alkaline delignification. Bioresour. Technol. 111, 447–452 (2012)

Palonen, H., Thomsen, A.B., Tenkanen, M., Schmidt, A.S., Viikari, L.: Evaluation of wet oxidation pretreatment for enzymatic hydrolysis of softwood. Appl. Biochem. Biotechnol. 117(1), 1–17 (2004)

Fox, M., Noike, T.: Wet oxidation pretreatment for the increase in anaerobic biodegradability of newspaper waste. Bioresour. Technol. 91(3), 273–281 (2004)

Laureano-Perez, L., Teymouri, F., Alizadeh, H., Dale, B.E.: Understanding factors that limit enzymatic hydrolysis of biomass. Appl. Biochem. Biotechnol. 124(1–3), 1081–1099 (2005)

Chundawat, S.P.S., Venkatesh, B., Dale, B.E.: Effect of particle size based separation of milled corn stover on AFEX pretreatment and enzymatic digestibility. Biotechnol. Bioeng. 96(2), 219–231 (2007)

Krishnan, C., Sousa, L.D.C., Jin, M., Chang, L., Dale, B.E., Balan, V.: Alkali-based AFEX pretreatment for the conversion of sugarcane bagasse and cane leaf residues to ethanol. Biotechnol. Bioeng. 107(3), 441–450 (2010)

Aita, G.A., Salvi, D.A., Walker, M.S.: Enzyme hydrolysis and ethanol fermentation of dilute ammonia pretreated energy cane. Bioresour. Technol. 102(6), 4444–4448 (2011)

Wyman, C.E., Dale, B.E., Elander, R.T., Holtzapple, M., Ladisch, M.R., Lee, Y.Y.: Comparative sugar recovery data from laboratory scale application of leading pretreatment technologies to corn stover. Bioresour. Technol. 96(18), 2026–2032 (2005)

Eggeman, T., Elander, R.T.: Process and economic analysis of pretreatment technologies. Bioresour. Technol. 96(18), 2019–2025 (2005)

Zheng, Y., Pan, Z., Zhang, R.: Overview of biomass pretreatment for cellulosic ethanol production. Int. J. Agric. Biol. Eng. 2(3), 51–68 (2009)

Sánchez, C.: Lignocellulosic residues: biodegradation and bioconversion by fungi. Biotechnol. Adv. 27(2), 185–194 (2009)

Sarkar, N., Ghosh, S.K., Bannerjee, S., Aikat, K.: Bioethanol production from agricultural wastes: an overview. Renew. Energy 37(1), 19–27 (2012)

Singh, P., Suman, A., Tiwari, P., Arya, N., Gaur, A., Shrivastava, A.K.: Biological pretreatment of sugarcane trash for its conversion to fermentable sugars. World J. Microbiol. Biotechnol. 24(5), 667–673 (2008)

Hamelinck, C.N., Van Hooijdonk, G., Faaij, A.P.C.: Ethanol from lignocellulosic biomass: techno-economic performance in short-, middle-and long-term. Biomass Bioenergy 28(4), 384–410 (2005)

Hahn-Hägerdal, B., Galbe, M., Gorwa-Grauslund, M.-F., Lidén, G., Zacchi, G.: Bio-ethanol–the fuel of tomorrow from the residues of today. Trends Biotechnol. 24(12), 549–556 (2006)

Yu, Q., Xu, C., Zhuang, X., Yuan, Z., He, M., Zhou, G.: Xylo-oligosaccharides and ethanol production from liquid hot water hydrolysate of sugarcane bagasse. BioResources 10(1), 30–40 (2015)

Rattanapoltee, P., Kaewkannetra, P.: Utilization of agricultural residues of pineapple peels and sugarcane bagasse as cost-saving raw materials in Scenedesmus acutus for lipid accumulation and biodiesel production. Appl. Biochem. Biotechnol. 173(6), 1495–1510 (2014)

Gupta, A., Verma, J.P.: Sustainable bio-ethanol production from agro-residues: a review. Renew. Sustain. Energy Rev. 41, 550–567 (2015)

Khatiwada, D., Leduc, S., Silveira, S., McCallum, I.: Optimizing ethanol and bioelectricity production in sugarcane biorefineries in Brazil. Renew. Energy 85, 371–386 (2016)

Cardona, C.A., Quintero, J.A., Paz, I.C.: Production of bioethanol from sugarcane bagasse: status and perspectives. Bioresour. Technol. 101(13), 4754–4766 (2010)

Shen, F., Hu, J., Zhong, Y., Liu, M.L.Y., Saddler, J.N., Liu, R.: Ethanol production from steam-pretreated sweet sorghum bagasse with high substrate consistency enzymatic hydrolysis. Biomass Bioenergy 41, 157–164 (2012)

da Silva Martins, L.H., Rabelo, S.C., da Costa, A.C.: Effects of the pretreatment method on high solids enzymatic hydrolysis and ethanol fermentation of the cellulosic fraction of sugarcane bagasse. Bioresour. Technol. 191, 312–321 (2015)

Huang, Y., Qin, X., Luo, X.-M., Nong, Q., Yang, Q., Zhang, Z., Gao, Y., Lv, F., Chen, Y., Yu, Z.: Efficient enzymatic hydrolysis and simultaneous saccharification and fermentation of sugarcane bagasse pulp for ethanol production by cellulase from Penicillium oxalicum EU2106 and thermotolerant Saccharomyces cerevisiae ZM1-5. Biomass Bioenergy 77, 53–63 (2015)

Liu, Y., Xu, J., Zhang, Y., Yuan, Z., He, M., Liang, C., Zhuang, X., Xie, J.: Sequential bioethanol and biogas production from sugarcane bagasse based on high solids fed-batch SSF. Energy 90, 1199–1205 (2015)

Capecchi, L., Galbe, M., Barbanti, L., Wallberg, O.: Combined ethanol and methane production using steam pretreated sugarcane bagasse. Ind. Crops Prod. 74, 255–262 (2015)

Taherzadeh, M.J., Karimi, K.: Enzymatic-based hydrolysis processes for ethanol from lignocellulosic materials: a review. BioResources 2(4), 707–738 (2007)

Giese, E.C., Chandel, A.K., Oliveira, I.S., Silva, S.S., Gonzalves, J.F., Correa, K.D.: Prospects for the bioethanol production from sugarcane feedstock: focus on Brazil. Nova Science Publishers, New York, NY, USA (2011)

Lin, Y., Tanaka, S.: Ethanol fermentation from biomass resources: current state and prospects. Appl. Microbiol. Biotechnol. 69(6), 627–642 (2006)

Antunes, F.A.F., Chandel, A.K., Milessi, T.S.S., Santos, J.C., Rosa, C.A., da Silva, S.S.: Bioethanol production from sugarcane bagasse by a novel Brazilian pentose fermenting yeast Scheffersomyces shehatae UFMG-HM 52.2: evaluation of fermentation medium. Int. J. Chem. Eng. 2014 (Article ID 180681), 8 (2014)

Chandra, R., Takeuchi, H., Hasegawa, T.: Methane production from lignocellulosic agricultural crop wastes: a review in context to second generation of biofuel production. Renew. Sustain. Energy Rev. 16(3), 1462–1476 (2012)

Moraes, B.S., Zaiat, M., Bonomi, A.: Anaerobic digestion of vinasse from sugarcane ethanol production in Brazil: challenges and perspectives. Renew. Sustain. Energy Rev. 44, 888–903 (2015)

Karellas, S., Boukis, I., Kontopoulos, G.: Development of an investment decision tool for biogas production from agricultural waste. Renew. Sustain. Energy Rev. 14(4), 1273–1282 (2010)

Janke, L., Leite, A., Nikolausz, M., Schmidt, T., Liebetrau, J., Nelles, M., Stinner, W.: Biogas production from sugarcane waste: assessment on kinetic challenges for process designing. Int. J. Mol. Sci. 16(9), 20685–20703 (2015)

Taherzadeh, M.J., Karimi, K.: Acid-based hydrolysis processes for ethanol from lignocellulosic materials: a review. BioResources 2(3), 472–499 (2007)

Kurakake, M., Ide, N., Komaki, T.: Biological pretreatment with two bacterial strains for enzymatic hydrolysis of office paper. Curr. Microbiol. 54(6), 424–428 (2007)

De Paoli, F., Bauer, A., Leonhartsberger, C., Amon, B., Amon, T.: Utilization of by-products from ethanol production as substrate for biogas production. Bioresour. Technol. 102(11), 6621–6624 (2011)

Rouf, M.A., Bajpai, P.K., Jotshi, C.K.: Optimization of biogas generation from press mud in batch reactor. Bangladesh J. Sci. Ind. Res. 45(4), 371–376 (2010)

Börjesson, P., Mattiasson, B.: Biogas as a resource-efficient vehicle fuel. Trends Biotechnol. 26(1), 7–13 (2008)

Rabelo, S.C., Carrere, H., MacielFilho, R., Costa, A.C.: Production of bioethanol, methane and heat from sugarcane bagasse in a biorefinery concept. Bioresour. Technol. 102(17), 7887–7895 (2011)

Baêta, B.E.L., Lima, D.R.S., Balena Filho, J.G., Adarme, O.F.H., Gurgel, L.V.A., de Aquino, S.F.: Evaluation of hydrogen and methane production from sugarcane bagasse hemicellulose hydrolysates by two-stage anaerobic digestion process. Bioresour. Technol. 218, 436–446 (2016)

Lai, Z., Zhu, M., Yang, X., Wang, J., Li, S.: Optimization of key factors affecting hydrogen production from sugarcane bagasse by a thermophilic anaerobic pure culture. Biotechnol. Biofuels 7(1), 1 (2014)

Urbaniec, K., Bakker, R.R.: Biomass residues as raw material for dark hydrogen fermentation—a review. Int. J. Hydrogen Energy 40(9), 3648–3658 (2015)

Hallenbeck, P.C., Abo-Hashesh, M., Ghosh, D.: Strategies for improving biological hydrogen production. Bioresour. Technol. 110, 1–9 (2012)

Hawkes, F.R., Hussy, I., Kyazze, G., Dinsdale, R., Hawkes, D.L.: Continuous dark fermentative hydrogen production by mesophilic microflora: principles and progress. Int. J. Hydrogen Energy 32(2), 172–184 (2007)

Kim, D.-H., Kim, S.-H., Shin, H.-S.: Sodium inhibition of fermentative hydrogen production. Int. J. Hydrogen Energy 34(8), 3295–3304 (2009)

Fan, Y.-T., Xing, Y., Ma, H.-C., Pan, C.-M., Hou, H.-W.: Enhanced cellulose-hydrogen production from corn stalk by lesser panda manure. Int. J. Hydrogen Energy 33(21), 6058–6065 (2008)

Wang, J., Wan, W.: Factors influencing fermentative hydrogen production: a review. Int. J. Hydrogen Energy 34(2), 799–811 (2009)

Rai, P.K., Singh, S.P., Asthana, R.K., Singh, S.: Biohydrogen production from sugarcane bagasse by integrating dark-and photo-fermentation. Bioresour. Technol. 152, 140–146 (2014)

Radjaram, B., Saravanane, R.: Start up study of UASB reactor treating press mud for biohydrogen production. Biomass Bioenergy 35(7), 2721–2728 (2011)

Radjaram, B., Saravanane, R.: Assessment of optimum dilution ratio for biohydrogen production by anaerobic co-digestion of press mud with sewage and water. Bioresour. Technol. 102(3), 2773–2780 (2011)

Lazaro, C.Z., Perna, V., Etchebehere, C., Varesche, M.B.A.: Sugarcane vinasse as substrate for fermentative hydrogen production: the effects of temperature and substrate concentration. Int. J. Hydrogen Energy 39(12), 6407–6418 (2014)

Ghimire, A., Frunzo, L., Pirozzi, F., Trably, E., Escudie, R., Lens, P.N.L., Esposito, G.: A review on dark fermentative biohydrogen production from organic biomass: process parameters and use of by-products. Appl. Energy 144, 73–95 (2015)

Couto, S.R., Sanromán, M.A.: Application of solid-state fermentation to ligninolytic enzyme production. Biochem. Eng. J. 22(3), 211–219 (2005)

Singhania, R.R., Sukumaran, R.K., Pillai, A., Prema, P., Szakacs, G., Pandey, A.: Solid-state fermentation of lignocellulosic substrates for cellulase production by Trichoderma reesei NRRL 11460. Indian J. Biotechnol. 5(3), 332–336 (2006)

Rodríguez-Zúñiga, U.F., Neto, V.B., Couri, S., Crestana, S., Farinas, C.S.: Use of spectroscopic and imaging techniques to evaluate pretreated sugarcane bagasse as a substrate for cellulase production under solid-state fermentation. Appl. Biochem. Biotechnol. 172(5), 2348–2362 (2014)

de Castro, A.M., de Carvalho, M.L.D.A., Leite, S.G.F., Pereira Jr., N.: Cellulases from Penicillium funiculosum: production, properties and application to cellulose hydrolysis. J. Ind. Microbiol. Biotechnol. 37(2), 151–158 (2010)

Cassia Pereira, J., Paganini Marques, N., Rodrigues, A., Brito de Oliveira, T., Boscolo, M., Silva, R.D., Gomes, E., Bocchini Martins, D.A.: Thermophilic fungi as new sources for production of cellulases and xylanases with potential use in sugarcane bagasse saccharification. J. Appl. Microbiol. 118(4), 928–939 (2015)

Kumar, R., Singh, S., Singh, O.V.: Bioconversion of lignocellulosic biomass: biochemical and molecular perspectives. J. Ind. Microbiol. Biotechnol. 35(5), 377–391 (2008)

Abdel-Rahman, M.A., Tashiro, Y., Sonomoto, K.: Lactic acid production from lignocellulose-derived sugars using lactic acid bacteria: overview and limits. J. Biotechnol. 156(4), 286–301 (2011)

Yadegary, M., Hamidi, A., Alavi, S.A., Khodaverdi, E., Yahaghi, H., Sattari, S., Bagherpour, G., Yahaghi, E.: Citric acid production from sugarcane bagasse through solid state fermentation method using Aspergillus niger mold and optimization of citric acid production by Taguchi method. Jundishapur J. Microbiol. 6(9), 1–6 (2013)

Adsul, M.G., Varma, A.J., Gokhale, D.V.: Lactic acid production from waste sugarcane bagasse derived cellulose. Green Chem. 9(1), 58–62 (2007)

Dumbrepatil, A., Adsul, M., Chaudhari, S., Khire, J., Gokhale, D.: Utilization of molasses sugar for lactic acid production by Lactobacillus delbrueckii subsp. delbrueckii mutant Uc-3 in batch fermentation. Appl. Environ. Microbiol. 74(1), 333–335 (2008)

Liang, L., Liu, R., Li, F., Wu, M., Chen, K., Ma, J., Jiang, M., Wei, P., Ouyang, P.: Repetitive succinic acid production from lignocellulose hydrolysates by enhancement of ATP supply in metabolically engineered Escherichia coli. Bioresour. Technol. 143, 405–412 (2013)

Brandão, P.C., Souza, T.C., Ferreira, C.A., Hori, C.E., Romanielo, L.L.: Removal of petroleum hydrocarbons from aqueous solution using sugarcane bagasse as adsorbent. J. Hazard. Mater. 175(1), 1106–1112 (2010)

Miretzky, P., Cirelli, A.F.: Cr (VI) and Cr(III) removal from aqueous solution by raw and modified lignocellulosic materials: a review. J. Hazard. Mater. 180(1), 1–19 (2010)

Mack, C., Wilhelmi, B., Duncan, J.R., Burgess, J.E.: Biosorption of precious metals. Biotechnol. Adv. 25(3), 264–271 (2007)

Kaur, S., Rani, S., Mahajan, R.K.: Adsorptive removal of dye crystal violet onto low-cost carbon produced from Eichhornia plant: kinetic, equilibrium, and thermodynamic studies. Desalination Water Treat. 53(2), 543–556 (2015)

Alomá, I., Martín-Lara, M.A., Rodríguez, I.L., Blázquez, G., Calero, M.: Removal of nickel (II) ions from aqueous solutions by biosorption on sugarcane bagasse. J. Taiwan Inst. Chem. Eng. 43(2), 275–281 (2012)

Wang, J., Chen, C.: Biosorbents for heavy metals removal and their future. Biotechnol. Adv. 27(2), 195–226 (2009)

Tao, H.-C., Zhang, H.-R., Li, J.-B., Ding, W.-Y.: Biomass based activated carbon obtained from sludge and sugarcane bagasse for removing lead ion from wastewater. Bioresour. Technol. 192, 611–617 (2015)

Esfandiar, N., Nasernejad, B., Ebadi, T.: Removal of Mn(II) from groundwater by sugarcane bagasse and activated carbon (a comparative study): application of response surface methodology (RSM). J. Ind. Eng. Chem. 20(5), 3726–3736 (2014)

Mohamad, M., Ahmad, H., Ismail, N., Morad, N., Samuding, K.: Enhancement of natural local soil in minimizing the migration of heavy metals using pressmud. Int. J. Adv. Agric. Environ. Eng. 1(1), 89–93 (2014)

Karnitz, O., Gurgel, L.V.A., Gil, L.F.: Removal of Ca(II) and Mg(II) from aqueous single metal solutions by mercerized cellulose and mercerized sugarcane bagasse grafted with EDTA dianhydride (EDTAD). Carbohydr. Polym. 79(1), 184–191 (2010)

Eyheraguibel, B., Silvestre, J.R.M., Morard, P.: Effects of humic substances derived from organic waste enhancement on the growth and mineral nutrition of maize. Bioresour. Technol. 99(10), 4206–4212 (2008)

Rahman, A., Begum, M.F., Rahman, M., Bari, M.A., Illias, G.N.M., Alam, M.F.: Isolation and identification of Trichoderma species from different habitats and their use for bioconversion of solid waste. Turk. J. Biol. 35(2), 183–194 (2011)

Vargas-Garcı, M.C., Suárez-Estrella, F., López, M.J., Moreno, J.: Effect of inoculation in composting processes: modifications in lignocellulosic fraction. Waste Manage. 27(9), 1099–1107 (2007)

Gupta, N., Tripathi, S., Balomajumder, C.: Characterization of pressmud: a sugar industry waste. Fuel 90(1), 389–394 (2011)

Mahamuni, S.V., Patil, A.S.: Microbial consortium treatment to distillery spent wash and press mud cake through pit and windrow system of composting. J. Chem. Biol. Phys. Sci. 2(2), 847–855 (2012)

Joshi, N., Sharma, S., Kangri, G.: Physico-chemical characterization of sulphidation press mud composted press mud and vermicomposted pressmud. Rep. Opin. 2(3), 79–82 (2010)

Kalaivanan, D., Hattab, K.O.: Influence of enriched pressmud compost on soil chemical properties and yield of rice. Res. J. Microbiol. 3(4), 254–261 (2008)

Sarker, T.C., Mannan, M.A., Mondol, P.C., Kabir, A.H., Parvez, S.M., Alam, M.F.: Physico-chemical profile and microbial diversity during bioconversion of sugarcane press mud using bacterial suspension. Not. Sci. Biol. 5(3), 346–353 (2013)

Khwairakpam, M., Bhargava, R.: Bioconversion of filter mud using vermicomposting employing two exotic and one local earthworm species. Bioresour. Technol. 100(23), 5846–5852 (2009)

Sangwan, P., Kaushik, C.P., Garg, V.K.: Vermicomposting of sugar industry waste (press mud) mixed with cow dung employing an epigeic earthworm Eisenia fetida. Waste Manage. Res. 28(1), 71–75 (2010)

Prakash, M., Karmegam, N.: Vermistabilization of pressmud using Perionyx ceylanensis Mich. Bioresour. Technol. 101(21), 8464–8468 (2010)

Kumar, R., Verma, D., Singh, B.L., Kumar, U.: Composting of sugar-cane waste by-products through treatment with microorganisms and subsequent vermicomposting. Bioresour. Technol. 101(17), 6707–6711 (2010)

Dominguez, M., Mejia, A., Revah, S., Barrios-González, J.: Optimization of bagasse, nutrients and initial moisture ratios on the yield of penicillin in solid-state fermentation. World J. Microbiol. Biotechnol. 17(7), 751–756 (2001)

Nigam, J.N.: Cultivation of Candida langeronii in sugar cane bagasse hemicellulosic hydrolyzate for the production of single cell protein. World J. Microbiol. Biotechnol. 16(4), 367–372 (2000)

Mandelli, F., Brenelli, L.B., Almeida, R.F., Goldbeck, R., Wolf, L.D., Hoffmam, Z.B., Ruller, R., Rocha, G.J.M., Mercadante, A.Z., Squina, F.M.: Simultaneous production of xylooligosaccharides and antioxidant compounds from sugarcane bagasse via enzymatic hydrolysis. Ind. Crops Prod. 52, 770–775 (2014)

Gebre, H., Fisha, K., Kindeya, T., Gebremichal, T.: Synthesis of furfural from bagasse. Int. Lett. Chem. Phys. Astron. 57, 72–84 (2015)

Baudel, H.M., Zaror, C., de Abreu, C.S.A.M.: Improving the value of sugarcane bagasse wastes via integrated chemical production systems: an environmentally friendly approach. Ind. Crops Prod. 21(3), 309–315 (2005)

Abd-Alla, A.: Microbial conversion of sugar cane phytosterol by Fusarium solani. Int. J. Anal. Pharm. Biomed. Sci. 2(4), 14–21 (2013)

Ou, S., Zhao, J., Wang, Y., Tian, Y., Wang, J.: Preparation of octacosanol from filter mud produced after sugarcane juice clarification. LWT Food Sci. Technol. 45(2), 295–298 (2012)

Suma, N., Reddy, B.S.V., Gloridoss, R.G., Prabhu, T.M., Kumar, C.B., Suresh, B.N., Shilpa, V.T.: Egg shell and yolk quality characteristics of layers fed with sugarcane press residue in soya and fish based diets. Vet. World 8(2), 232–238 (2015)

Bonomi, A., Cavalett, O., da Cunha, M.P., Lima, M.A.P.: The virtual sugarcane biorefinery concept. Virtual biorefinery, pp. 5–11. Springer, Berlin (2016)

Junqueira, T.L., Cavalett, O., Bonomi, A.: The virtual sugarcane biorefinery—a simulation tool to support public policies formulation in bioenergy. Ind. Biotechnol. 12(1), 62–67 (2016)

ISO: ISO Norm 14040:2006. Life Cycle Assessment: Principles and Framework. Environmental Management. International Organisation for Standardisation, Geneva (2006)

Dias, M.O.S., Junqueira, T.L., Cavalett, O., Cunha, M.P., Jesus, C.D.F., Rossell, C.E.V., Maciel Filho, R., Bonomi, A.: Integrated versus stand-alone second generation ethanol production from sugarcane bagasse and trash. Bioresour. Technol. 103(1), 152–161 (2012)

Moraes, B.S., Junqueira, T.L., Pavanello, L.G., Cavalett, O., Mantelatto, P.E., Bonomi, A., Zaiat, M.: Anaerobic digestion of vinasse from sugarcane biorefineries in Brazil from energy, environmental, and economic perspectives: profit or expense? Appl. Energy 113, 825–835 (2014)

Pereira, L.G., Chagas, M.F., Dias, M.O.S., Cavalett, O., Bonomi, A.: Life cycle assessment of butanol production in sugarcane biorefineries in Brazil. J. Clean. Prod. 96, 557–568 (2015)

Pereira, L.G., Chagas, M.F., Dias, M.O.S., Cavalett, O., Bonomi, A.: Life cycle assessment of biobutanol production integrated to sugarcane biorefineries in Brazil. In: “Integrating cleaner production into sustainability strategies” 4th International Workshop, São Paulo, Brazil, 22–24 May, 2013

de Moraes Rocha, G.J., Nascimento, V.M., Goncalves, A.R., Silva, V.F.N., Martín, C.: Influence of mixed sugarcane bagasse samples evaluated by elemental and physical–chemical composition. Ind. Crops Prod. 64, 52–58 (2015)

Liu, C.-F., Sun, R.-C., Qin, M.-H., Zhang, A.-P., Ren, J.-L., Xu, F., Ye, J., Wu, S.-B.: Chemical modification of ultrasound-pretreated sugarcane bagasse with maleic anhydride. Ind. Crops Prod. 26(2), 212–219 (2007)

Peng, F., Ren, J.-L., Xu, F., Bian, J., Peng, P., Sun, R.-C.: Comparative study of hemicelluloses obtained by graded ethanol precipitation from sugarcane bagasse. J. Agric. Food Chem. 57(14), 6305–6317 (2009)

Zhang, Z., O’Hara, I.M., Doherty, W.O.S.: Pretreatment of sugarcane bagasse by acid-catalysed process in aqueous ionic liquid solutions. Bioresour. Technol. 120, 149–156 (2012)

Chandel, A.K., Kapoor, R.K., Singh, A., Kuhad, R.C.: Detoxification of sugarcane bagasse hydrolysate improves ethanol production by Candida shehatae NCIM 3501. Bioresour. Technol. 98(10), 1947–1950 (2007)

Pattra, S., Sangyoka, S., Boonmee, M., Reungsang, A.: Bio-hydrogen production from the fermentation of sugarcane bagasse hydrolysate by Clostridium butyricum. Int. J. Hydrogen Energy 33(19), 5256–5265 (2008)

Cheng, K.-K., Cai, B.-Y., Zhang, J.-A., Ling, H.-Z., Zhou, Y.-J., Ge, J.-P., Xu, J.-M.: Sugarcane bagasse hemicellulose hydrolysate for ethanol production by acid recovery process. Biochem. Eng. J. 38(1), 105–109 (2008)

Zhao, X., Song, Y., Liu, D.: Enzymatic hydrolysis and simultaneous saccharification and fermentation of alkali/peracetic acid-pretreated sugarcane bagasse for ethanol and 2,3-butanediol production. Enzyme Microb. Technol. 49(4), 413–419 (2011)

Rodríguez-Chong, A., Ramírez, J.A., Garrote, G., Vázquez, M.: Hydrolysis of sugar cane bagasse using nitric acid: a kinetic assessment. J. Food Eng. 61(2), 143–152 (2004)

Gámez, S., González-Cabriales, J.J., Ramírez, J.A., Garrote, G., Vázquez, M.: Study of the hydrolysis of sugar cane bagasse using phosphoric acid. J. Food Eng. 74(1), 78–88 (2006)

Pasquini, D., Pimenta, M.T.B., Ferreira, L.H., Curvelo, A.A.S.: Sugar cane bagasse pulping using supercritical CO 2 associated with co-solvent 1-butanol/water. J. Supercrit. Fluids 34(2), 125–131 (2005)

Pasquini, D., Pimenta, M.T.B., Ferreira, L.H., da Silva Curvelo, A.A.: Extraction of lignin from sugar cane bagasse and Pinus taeda wood chips using ethanol—water mixtures and carbon dioxide at high pressures. J. Supercrit. Fluids 36(1), 31–39 (2005)

González, L.M.L., Vervaeren, H., Reyes, I.P., Dumoulin, A., Romero, O.R., Dewulf, J.: Thermo-chemical pre-treatment to solubilize and improve anaerobic biodegradability of press mud. Bioresour. Technol. 131, 250–257 (2013)

Vallejos, M.E., Felissia, F.E., Kruyeniski, J., Area, M.C.: Kinetic study of the extraction of hemicellulosic carbohydrates from sugarcane bagasse by hot water treatment. Ind. Crops Prod. 67, 1–6 (2015)

Batalha, L.A.R., Han, Q., Jameel, H., Chang, H.-M., Colodette, J.L., Gomes, F.J.B.: Production of fermentable sugars from sugarcane bagasse by enzymatic hydrolysis after autohydrolysis and mechanical refining. Bioresour. Technol. 180, 97–105 (2015)

Sendelius, J.: Steam pretreatment optimization for sugarcane bagasse in bioethanol production. Master of Science Thesis. Department of Chemical Engineering, Lund University, Sweden (2005)

Schneider, W.D.H., dos Reis, L., Camassola, M., Dillon, A.J.P.: Morphogenesis and production of enzymes by Penicillium echinulatum in response to different carbon sources. BioMed Res. Int. 2014, 1–10 (2014)

Guilherme, A.A., Dantas, P.V.F., Santos, E.S., Fernandes, F.A.N., Macedo, G.R.: Evaluation of composition, characterization and enzymatic hydrolysis of pretreated sugar cane bagasse. Braz. J. Chem. Eng. 32(1), 23–33 (2015)

Binod, P., Satyanagalakshmi, K., Sindhu, R., Janu, K.U., Sukumaran, R.K., Pandey, A.: Short duration microwave assisted pretreatment enhances the enzymatic saccharification and fermentable sugar yield from sugarcane bagasse. Renew. Energy 37(1), 109–116 (2012)

Qiu, Z., Aita, G.M., Walker, M.S.: Effect of ionic liquid pretreatment on the chemical composition, structure and enzymatic hydrolysis of energy cane bagasse. Bioresour. Technol. 117, 251–256 (2012)

Zhao, X.B., Wang, L., Liu, D.H.: Effect of several factors on peracetic acid pretreatment of sugarcane bagasse for enzymatic hydrolysis. J. Chem. Technol. Biotechnol. 82(12), 1115–1121 (2007)

Das, P., Ganesh, A., Wangikar, P.: Influence of pretreatment for deashing of sugarcane bagasse on pyrolysis products. Biomass Bioenergy 27(5), 445–457 (2004)

Sindhu, R., Kuttiraja, M., Binod, P., Sukumaran, R.K., Pandey, A.: Physicochemical characterization of alkali pretreated sugarcane tops and optimization of enzymatic saccharification using response surface methodology. Renew. Energy 62, 362–368 (2014)

Dos Santos, D.D.S., Camelo, A.C., Rodrigues, K.C.P., Carlos, L.C., Pereira Jr., N.: Ethanol production from sugarcane bagasse by Zymomonas mobilis using simultaneous saccharification and fermentation (SSF) process. Appl. Biochem. Biotechnol. 161(1–8), 93–105 (2010)

Martins, E.S., Silva, D., Da Silva, R., Gomes, E.: Solid state production of thermostable pectinases from thermophilic Thermoascus aurantiacus. Process Biochem. 37(9), 949–954 (2002)

Martín, C., Marcet, M., Almazán, O., Jönsson, L.J.: Adaptation of a recombinant xylose-utilizing Saccharomyces cerevisiae strain to a sugarcane bagasse hydrolysate with high content of fermentation inhibitors. Bioresour. Technol. 98(9), 1767–1773 (2007)

Rouf, M.A., Islam, M.S., Bajpai, P.K., Jotshic, C.K.: Techno-economic assessment of biogas production from press mud in Bangladesh. Bangladesh J. Sci. Ind. Res. 48(1), 51–58 (2013)

Janke, L., Leite, A.F., Nikolausz, M., Radetski, C.M., Nelles, M., Stinner, W.: Comparison of start-up strategies and process performance during semi-continuous anaerobic digestion of sugarcane filter cake co-digested with bagasse. Waste Manage. 48, 199–208 (2016)

Bolado-Rodríguez, S., Toquero, C., Martín-Juárez, J., Travaini, R., García-Encina, P.A.: Effect of thermal, acid, alkaline and alkaline-peroxide pretreatments on the biochemical methane potential and kinetics of the anaerobic digestion of wheat straw and sugarcane bagasse. Bioresour. Technol. 201, 182–190 (2016)

Fangkum, A., Reungsang, A.: Biohydrogen production from sugarcane bagasse hydrolysate by elephant dung: effects of initial pH and substrate concentration. Int. J. Hydrogen Energy 36(14), 8687–8696 (2011)

Bocchini, D.A., Oliveira, O., Gomes, E., Da Silva, R.: Use of sugarcane bagasse and grass hydrolysates as carbon sources for xylanase production by Bacillus circulans D1 in submerged fermentation. Process Biochem. 40(12), 3653–3659 (2005)

Milagres, A.M.F., Santos, E., Piovan, T., Roberto, I.C.: Production of xylanase by Thermoascus aurantiacus from sugar cane bagasse in an aerated growth fermentor. Process Biochem. 39(11), 1387–1391 (2004)

Pandey, P., Pandey, A.K.: Production of cellulase-free thermostable xylanases by an isolated strain of Aspergillus niger PPI, utilizing various lignocellulosic wastes. World J. Microbiol. Biotechnol. 18(3), 281–283 (2002)

Oliveira, L.A., Porto, A.L.F., Tambourgi, E.B.: Production of xylanase and protease by Penicillium janthinellum CRC 87M-115 from different agricultural wastes. Bioresour. Technol. 97(6), 862–867 (2006)

Muthuvelayudham, R., Viruthagiri, T.: Fermentative production and kinetics of cellulase protein on Trichoderma reesei using sugarcane bagasse and rice straw. Afr. J. Biotechnol. 5(20), 1873–1881 (2006)

Ojumu, T.V., Solomon, B.O., Betiku, E., Layokun, S.K., Amigun, B.: Cellulase production by Aspergillus flavus Linn Isolate NSPR 101 fermented in sawdust, bagasse and corncob. Afr. J. Biotechnol. 2(6), 150–152 (2003)

Martin, N., Souza, S.R.D., Silva, R.D., Gomes, E.: Pectinase production by fungal strains in solid-state fermentation using agro-industrial bioproduct. Braz. Arch. Biol. Technol. 47(5), 813–819 (2004)

Silva, D., Martins, E.D.S., Silva, R.D., Gomes, E.: Pectinase production by Penicillium viridicatum RFC3 by solid state fermentation using agricultural wastes and agro-industrial by-products. Braz. J. Microbiol. 33(4), 318–324 (2002)

Ferreira, V., Da Silva, R., Silva, D., Gomes, E.: Production of pectate lyase by Penicillium viridicatum RFC3 in solid-state and submerged fermentation. Int. J. Microbiol. 2010, 1–8 (2010)

Singh, A., Bajar, S., Bishnoi, N.R., Singh, N.: Laccase production by Aspergillus heteromorphus using distillery spent wash and lignocellulosic biomass. J. Hazard. Mater. 176(1), 1079–1082 (2010)

Mazutti, M.A., Zabot, G., Boni, G., Skovronski, A., de Oliveira, D., Di Luccio, M., Rodrigues, M.I., Treichel, H., Maugeri, F.: Optimization of inulinase production by solid-state fermentation in a packed-bed bioreactor. J. Chem. Technol. Biotechnol. 85(1), 109–114 (2010)

Mohapatra, P.K.D., Mondal, K.C., Pati, B.R.: Production of tannase by the immobilized cells of Bacillus licheniformis KBR6 in Ca-alginate beads. J. Appl. Microbiol. 102(6), 1462–1467 (2007)

Rajagopalan, G., Krishnan, C.: α-Amylase production from catabolite derepressed Bacillus subtilis KCC103 utilizing sugarcane bagasse hydrolysate. Bioresour. Technol. 99(8), 3044–3050 (2008)

Rodriguez, J.A., Mateos, J.C., Nungaray, J., Gonzále, V., Bhagnagar, T., Roussos, S., Cordova, J., Baratti, J.: Improving lipase production by nutrient source modification using Rhizopus homothallicus cultured in solid state fermentation. Process Biochem. 41(11), 2264–2269 (2006)

Laopaiboon, P., Thani, A., Leelavatcharamas, V., Laopaiboon, L.: Acid hydrolysis of sugarcane bagasse for lactic acid production. Bioresour. Technol. 101(3), 1036–1043 (2010)

John, R.P., Nampoothiri, K.M., Pandey, A.: Solid-state fermentation for l-lactic acid production from agro wastes using Lactobacillus delbrueckii. Process Biochem. 41(4), 759–763 (2006)

Kumar, D., Jain, V.K., Shanker, G., Srivastava, A.: Citric acid production by solid state fermentation using sugarcane bagasse. Process Biochem. 38(12), 1731–1738 (2003)

Khosravi-Darani, K., Zoghi, A.: Comparison of pretreatment strategies of sugarcane baggase: experimental design for citric acid production. Bioresour. Technol. 99(15), 6986–6993 (2008)

Liu, R., Liang, L., Li, F., Wu, M., Chen, K., Ma, J., Jiang, M., Wei, P., Ouyang, P.: Efficient succinic acid production from lignocellulosic biomass by simultaneous utilization of glucose and xylose in engineered Escherichia coli. Bioresour. Technol. 149, 84–91 (2013)

Xi, Y.-L., Dai, W.-Y., Xu, R., Zhang, J.-H., Chen, K.-Q., Jiang, M., Wei, P., Ouyang, P.-K.: Ultrasonic pretreatment and acid hydrolysis of sugarcane bagasse for succinic acid production using Actinobacillus succinogenes. Bioprocess Biosyst. Eng. 36(11), 1779–1785 (2013)

Jiang, M., Xu, R., Xi, Y.-L., Zhang, J.-H., Dai, W.-Y., Wan, Y.-J., Chen, K.-Q., Wei, P.: Succinic acid production from cellobiose by Actinobacillus succinogenes. Bioresour. Technol. 135, 469–474 (2013)

Singh, O.V., Jain, R.K., Singh, R.P.: Gluconic acid production under varying fermentation conditions by Aspergillus niger. J. Chem. Technol. Biotechnol. 78(2–3), 208–212 (2003)

Behnood, R., Anvaripour, B., Jaafarzade Haghighi Fard, N., Farasati, M.: Petroleum hydrocarbons adsorption from aqueous solution by raw sugarcane bagasse. Int. J. Emerg. Sci. Eng. 1(6), 96–99 (2013)

Garg, U.K., Kaur, M.P., Garg, V.K., Sud, D.: Removal of nickel (II) from aqueous solution by adsorption on agricultural waste biomass using a response surface methodological approach. Bioresour. Technol. 99(5), 1325–1331 (2008)

Garg, U., Kaur, M.P., Jawa, G.K., Sud, D., Garg, V.K.: Removal of cadmium (II) from aqueous solutions by adsorption on agricultural waste biomass. J. Hazard. Mater. 154(1), 1149–1157 (2008)

Zhang, Z., O’Hara, I.M., Kent, G.A., Doherty, W.O.S.: Comparative study on adsorption of two cationic dyes by milled sugarcane bagasse. Ind. Crops Prod. 42, 41–49 (2013)

Ullah, I., Nadeem, R., Iqbal, M., Manzoor, Q.: Biosorption of chromium onto native and immobilized sugarcane bagasse waste biomass. Ecol. Eng. 60, 99–107 (2013)

Niu, X., Zheng, L., Zhou, J., Dang, Z., Li, Z.: Synthesis of an adsorbent from sugarcane bagass by graft copolymerization and its utilization to remove Cd (II) ions from aqueous solution. J. Taiwan Inst. Chem. Eng. 45(5), 2557–2564 (2014)

Yu, J.-X., Wang, L.-Y., Chi, R.-A., Zhang, Y.-F., Xu, Z.-G., Guo, J.: Competitive adsorption of Pb2+ and Cd2+ on magnetic modified sugarcane bagasse prepared by two simple steps. Appl. Surf. Sci. 268, 163–170 (2013)

Gurgel, L.V.A., de Freitas, R.P., Gil, L.F.: Adsorption of Cu (II), Cd (II), and Pb(II) from aqueous single metal solutions by sugarcane bagasse and mercerized sugarcane bagasse chemically modified with succinic anhydride. Carbohydr. Polym. 74(4), 922–929 (2008)

Júnior, O.K., Gurgel, L.V.A., de Freitas, R.P., Gil, L.F.: Adsorption of Cu(II), Cd(II), and Pb(II) from aqueous single metal solutions by mercerized cellulose and mercerized sugarcane bagasse chemically modified with EDTA dianhydride (EDTAD). Carbohydr. Polym. 77(3), 643–650 (2009)

Xing, Y., Liu, D., Zhang, L.-P.: Enhanced adsorption of methylene blue by EDTAD-modified sugarcane bagasse and photocatalytic regeneration of the adsorbent. Desalination 259(1), 187–191 (2010)

Karnitz, O., Gurgel, L.V.A., De Melo, J.C.P., Botaro, V.R., Melo, T.N.M.R.S., de Freitas Gil, R.P., Gil, L.F.: Adsorption of heavy metal ion from aqueous single metal solution by chemically modified sugarcane bagasse. Bioresour. Technol. 98(6), 1291–1297 (2007)

Mulinari, D.R., da Silva, M.L.C.C.P.: Adsorption of sulphate ions by modification of sugarcane bagasse cellulose. Carbohydr. Polym. 74(3), 617–620 (2008)

Rana, K., Shah, M., Limbachiya, N.: Adsorption of copper Cu2+ metal ion from waste water using sulphuric acid treated sugarcane bagasse as adsorbent. Int. J. Adv. Eng. Res. Sci. 1(1), 55–59 (2014)

Homagai, P.L., Ghimire, K.N., Inoue, K.: Adsorption behavior of heavy metals onto chemically modified sugarcane bagasse. Bioresour. Technol. 101(6), 2067–2069 (2010)

Gusmão, K.A.G., Gurgel, L.V.A., Melo, T.M.S., Gil, L.F.: Application of succinylated sugarcane bagasse as adsorbent to remove methylene blue and gentian violet from aqueous solutions—kinetic and equilibrium studies. Dyes Pigments 92(3), 967–974 (2012)

Khoramzadeh, E., Nasernejad, B., Halladj, R.: Mercury biosorption from aqueous solutions by sugarcane bagasse. J. Taiwan Inst. Chem. Eng. 44(2), 266–269 (2013)

Pehlivan, E., Tran, H.T., Ouédraogo, W.K.I., Schmidt, C., Zachmann, D., Bahadir, M.: Sugarcane bagasse treated with hydrous ferric oxide as a potential adsorbent for the removal of As(V) from aqueous solutions. Food Chem. 138(1), 133–138 (2013)

Zaheer, S., Bhatti, H.N., Sdaf, S., Safa, Y., Zia-ur-Ruhman, M.: Biosorptioncharateristics of sugarcane bagasse for the removal of foron blue E-BL bye from aqueous solutions. J. Anim. Plants Sci. 24(1), 272–279 (2014)

Ayyappan, R., Sophia, A.C., Swaminathan, K., Sandhya, S.: Removal of Pb(II) from aqueous solution using carbon derived from agricultural wastes. Process Biochem. 40(3), 1293–1299 (2005)

Kalderis, D., Koutoulakis, D., Paraskeva, P., Diamadopoulos, E., Otal, E., del Valle, J.O., Fernández-Pereira, C.: Adsorption of polluting substances on activated carbons prepared from rice husk and sugarcane bagasse. Chem. Eng. J. 144(1), 42–50 (2008)

Amin, N.K.: Removal of reactive dye from aqueous solutions by adsorption onto activated carbons prepared from sugarcane bagasse pith. Desalination 223(1), 152–161 (2008)

Acknowledgments

We are really thankful to Dr. Ahmed abd-El Gawad for extensively editing the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sarker, T.C., Azam, S.M.G.G. & Bonanomi, G. Recent Advances in Sugarcane Industry Solid By-Products Valorization. Waste Biomass Valor 8, 241–266 (2017). https://doi.org/10.1007/s12649-016-9665-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9665-3