Abstract

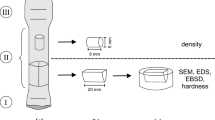

Heat-resistant aluminum alloys are generally developed by dispersing stable intermetallic compounds by adding transition metals (TM) whose diffusion coefficient in aluminum alloys is low even at high temperatures. Commonly used intermetallic compounds include Al-TM binary intermetallic compounds, for example, Al6Fe, Al3Ti and Al3Ni. By contrast, multicomponent intermetallic compounds are hardly used. The present study focuses on Al-Mn-Cu and Al-Mn-Ni ternary intermetallic compounds, and by finely dispersing these intermetallic compounds, attempts to develop heat-resistant alloys. Through the atomization method, Al-(4.96–5.96)Mn-(6.82–7.53)Cu-0.4Zr and Al-(5.48–8.76)Mn-(2.23–4.32)Ni-0.4Zr (in mass%) powders were fabricated, and by degassing these powders at 773 K, intermetallic compounds were precipitated. These powders were then solidified into extrudates by hot extrusion at 773 K. The microstructural characterization of powders and exrudates was carried out by XRD analysis, SEM/EDX and TEM. The mechanical properties of extrudates were determined at room temperature, 523 K and 573 K. In Al-Mn-Cu alloys, while a small amount of Al2Cu was crystallized, precipitated Al20Mn3Cu2 intermetallic compounds were mainly dispersed. In Al-Mn-Ni alloys, while a small amount of Al6Mn intermetallic compounds was precipitated, the precipitated A60Mn11Ni4 intermetallic compounds were mainly dispersed. Both ternary intermetallic compounds were about 200 nm in size. The compounds were elliptical, and their longitudinal direction was oriented along the extrusion direction. In the Al-Mn-Cu alloys, since the work hardening at room temperature was high, the tensile strength became 569 MPa. At elevated temperatures, since hardly any work hardening was observed, the tensile strength decreased markedly. However, in Al-Mn-Ni alloys, since the work hardening is low even at room temperature, the roomtemperature strength is not high. Thus, the decrease in tensile strength at elevated temperatures is relatively small and a high strength was obtained at 523 K and 573 K: 276 MPa and 207 MPa, respectively.

Similar content being viewed by others

References

Griffith W M, Sanders Jr R E and Hildman G J, High-Strength POwder Metallurgy Aluminum Alloys. Koczak MJ and Hildeman GJ, editors, The Metallurgical Society of AIME. (1984) 209.

Langerbeck S L, Griffith W M, Hildmn G J and Simon G W, Rapidly Solidified Powder Aluminum Alloys. Fine ME and Starke EA, editors, ASTM, STP 890 (1984).

Premkumar M K, Lawley A and Koczak K J, Processing and Microstructure of Powder Metallurgy Al-Fe-Ni Alloys. Met. Trans. A, 23 (1992) 3219.

Adachi H, Osamura K and Kusui J, Mechanical Properties of Dispersion-Hardened P/M Al-Mn-Cu-Mg-Zn Alloys at Elevated Temperature. Mater. Sci. For., 519–521 (2006) 419.

Robinson K, The Unit Cell and Brillouin Zone of Ni4Mn11Al60 and Related Compounds. Phil. Mag., 43 (1952) 775.

Adachi H, Osamura K, Tanahashi T, Kikuchi K and Kusui. Effect of Zr Addition on Microstructure of Hot Extruded P/M Al-Zn-Mg-Cu Alloys. J. J. JILM, 55 (2005) 164.

Izumi F and Ikeda T, A Rietveld-Analysis Program RIETAN-98 and its Applications to Zerolites. Mater. Sci. For., 321–324 (2000) 198.

Harada K and Suga H, Solidified Structure of Contrifugally Atomized Powders. J. Jap. Soc. Pow. Powder Met., 40 (1993) 1154.

Son S K, Takeda M and Endo T, Microstructures and Thermal Stability of Metastable-Phase Precipitates Formed in an Al-Cu Alloys at 463K. Z. Metallkd., 96 (2005) 358.

Dix E H, Fink W L and Willey L A, Equlibrium Relations in Aluminum-Manganese Alloys of High Purity, II, Trans. AIME. 104 (1933) 335.

Fink W L and Willey L A, Equlibrium Relations in Aluminum-Nickel Alloys of High Purity. Trans. AIME., 111 (1934) 293.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Adachi, H., Itaka, W., Aida, T. et al. Microstructure and mechanical properties of ternary intermetallic compound dispersed P/M Al-Mn-X-Zr (x=Cu,Ni) alloys. Trans Indian Inst Met 62, 163–167 (2009). https://doi.org/10.1007/s12666-009-0023-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-009-0023-z