Abstract

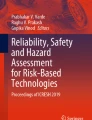

Fretting fatigue damage occurs in contacting parts when they are subjected to fluctuating loads and sliding movements at the same time. Fretting fatigue can reduce the fatigue life of materials by half or even more. Fretting fatigue tests are usually performed using universal hydraulic testing devices. The contact pressure is produced by a fixture, typically designed and manufactured by researchers. In this investigation, a new device is introduced in which the fluctuating loading is supplied by a variable crank system (VCSD). The device called VCSD for abbreviation is basically a position control machine in which displacements can be imposed with an accuracy of 0.01 mm. The axial and contact loads are measured by load cells. The friction load is also measured by using foil strain gauges using a Wheatstone bridge configuration. The functionality of the device is examined by making a comparison between fretting fatigue lives of a number of Al7075-T6 specimens tested on a universal testing machine and VCSD. The results show a very close agreement between the functionality of the two testing rigs. The main advantages of VCSD are its higher frequency with respect to universal devices, simplicity, and cheapness. It can be developed further for high and low temperature tests in future.

Similar content being viewed by others

References

Hills D A and Nowell D, Mechanics of fretting fatigue, Kluwer Academic Publisher, (1994).

Anderson T L, Fracture Mechanics: Fundamentals and Application, Second Edition, CRC Press, (1994).

Prithvi Raj Arora, Jacob M S D, Mohd. Sapuan Salit, Elsadig Mahdi Ahmed, Saleem M, Prasetyo Edi, Experimental evaluation of fretting fatigue test apparatus, International Journal of Fatigue 29 (2007) 941.

Matlik J F, Farris T N, Haake F K, Swanson G R and Duke G C, High-frequency, high-temperature fretting-fatigue experiments, Wear, 261 (2006) 13672.

Matlik J F, Farris T N, High-frequency fretting fatigue experiments, in: Mutoh Y, Kinyon S E, Hoeppner D W (Eds.), Fretting Fatigue: Advances in the Basic Understanding and Applications, ASTM STP 1425, American Society of Testing and Materials, West Conshohocken, PA, (2003) 251.

Hills D A, Nowell D, The development of a fretting fatigue experiment with well-defined characteristics, in: Attia, M.H, Waterhouse R.B. (Eds.), Standardization of Fretting Fatigue: Test Methods and Equipment, ASTM STP 1159, American Society of Testing and Materials, Philadelphia, PA, (1992) 69.

Murthy H, Rajeev P, Okane M and Farris T N, Development of test methods for high temperature fretting of turbine materials subjected to engine type loading, in: Mutoh Y, Kinyon S E, Hoeppner D W (Eds.), Fretting Fatigue: Advances in the Basic Understanding and Applications, ASTM STP 1425, American Society of Testing and Materials, West Conshohocken, PA, (2003) 273.

Majzoobi G H and Jaleh M, Duplex surface treatments on AL7075-T6 alloy against fretting fatigue behavior by application of titanium coating plus nitriding, Materials Science and Engineering: A, 452–453 (2007) 673.

Novin Rooz A., Majzoobi G.H., Nemati J. 2, Farrahi G.H.., The Effects of Chrome and Titanium Coating on Fretting Fatigue Resistance of Aluminum Alloy 7075-T6, Steel research int. 79 (2008), Special Edition Metal Forming Conference 2008, 2 (2008) 145.

Majzoobi G.H., Nemati J., Novin Rooz A.J., Farrahi GH., Modification of Fretting Fatigue behavior of AL7075-T6 alloy by application of Titanium Coating and shot Peening, Tribology International, 42 (2009) 121.

Gutkin R and Alfredsson B, Growth of fretting fatigue cracks in a shrink-fitted joint subjected to rotating bending, Engineering Failure Analysis, 15 (2007) 582.

Rajasekaran R, Nowell D, Fretting fatigue in dovetail blade roots: Experiment and analysis, Tribology International, 39 (2006) 1277.

Ryuichiro Ebara and Masanori Fujimura, Fretting fatigue behavior of Ti-6Al-4V alloy under plane bending stress and contact stress, Tribology International, 39 (2006) 1181.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Majzoobi, G.H., Hojjati, R., Nematian, M. et al. A new device for fretting fatigue testing. Trans Indian Inst Met 63, 493–497 (2010). https://doi.org/10.1007/s12666-010-0070-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-010-0070-5