Abstract

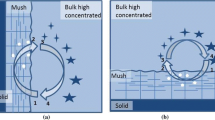

During solidification of castings, equiaxed crystals that is formed sink downwards, sediment and form a packed bed. The behavior of separated moving crystals can be described by a submerged object approach, whereas the viscoplastic behavior of a semi-solid slurry follows a volume-averaged viscoplastic constitutive equation. In this work, a two-phase Eulerian–Eulerian volume-averaging approach is used to combine both flow regimes. The transition happens at a certain solid volume fraction, the so-called coherency limit. Starting with a uniform distribution of crystals at rest, sedimentation and packing of crystals are described. In addition, the material density of the crystal is assumed to increase on cooling and thus the domain shrinks which is also accounted for in this report. It is demonstrated how sensitive the model is, on the considered crystal diameters and on the assumed value for the coherency limits.

Similar content being viewed by others

Abbreviations

- α, β:

-

Rheological function taken from [9]

- c p,ℓ , c p,s :

-

Specific heat (J/kg/K)

- C ε :

-

Settling ratio (–)

- d :

-

Average crystal diameter (m)

- g ℓ , g s :

-

Volume fraction (–)

- \( g_s^{\text{pack}} \) :

-

Packing limit for hard spheres (–)

- \( g_s^{\text{cohe}} \) :

-

Coherency limit (–)

- h ℓ , h s :

-

Volume averaged enthalpy (J/kg)

- H*:

-

Volume heat transfer coefficient (W/m3/K)

- H ℓs :

-

Enthalpy exchange (J/m3/s)

- I :

-

Identity tensor (–)

- k ℓ , k s :

-

Heat conductivity (J/m2/K)

- K :

-

Permeability (m2)

- K v :

-

Viscoplastic consistency (kg sm−2/m)

- K ℓs :

-

Drag coefficient (kg/m3/s)

- m :

-

Strain rate sensitivity coefficient (–)

- M ℓs :

-

Mass transfer (kg/m3/s)

- p ℓ , p s :

-

Pressure (N/m2)

- T ℓ , T s :

-

Volume average temperature (K)

- v ℓ , v s :

-

Flow velocity (m/s)

- \({\dot{ \varvec{ \varepsilon }}_\ell },\;{\dot{ \varvec{ \varepsilon }}_s} \) :

-

Strain rate tensor (–)

- \( \dot \varepsilon_{eq}^s \) :

-

Equivalent strain rate (–)

- μ ℓ , μ s :

-

Viscosity (kg/m/s)

- ρ ℓ , ρ s :

-

Density (kg/m3)

- σ ℓ , σ s :

-

Stress tensor (N/m2)

- τ ℓ , τ s :

-

Deviatoric stress tensor (N/m2)

References

Verö J, Met Ind 48 (1936) 431.

Bishop H F, Ackerlind C G, and Pellini W S, AFS Trans 65 (1957) 247.

Laxmanan V, and Flemings M C, Met Trans A 11 (1980) 1927.

Suery M, and Flemings M C, Met Trans A 13 (1982) 1809.

Flemings M C, Met Trans B 22 (1991) 957.

Dahle A K, and Arnberg L, Acta Mater 45 (1997) 547.

Dahle A K, and StJohn D H, Acta Mater 47 (1998) 31.

Dahle A K, StJohn D H, Thevik H J, and Arnberg L, Metall Mater Trans B 30 (1999) 287.

Nguyen T G, Favier D, and Suery M, Int J Plast 10 (1994) 663.

Martin C L, Brown S B, Favier D, and Suery M, Mater Sci Eng 202 (1995) 13.

Martin C L, Favier D, and Suery M, Int J Plast 13 (1997) 237.

Martin C L, Favier D, and Suery M, Int J Plast 15 (1999) 981.

Ludwig O, Drezet J-M, Martin C L, and Suery M, Metall Mater Trans A 36 (2005) 1525.

Fachinotti V D, Le Corre S, Triolet N, Bobadilla M, and Bellet M, Int J Numer Methods Eng 67 (2006) 1341.

Bellet M, in 9th International Conference on Numerical Methods in Industrial Forming Processes, (eds) Cesar de Sa J M A, and Santos A D, American Institute of Physics, Porto (2007), p 1369.

Kumar A, and Dutta P, Int J Heat Mass Transf 48 (2005) 3674.

Kumar A, Walker M J, Sundarraj S, and Dutta P, Metall Mater Trans B 42 (2011) 825.

Kumar A, Walker M J, Sundarraj S, and Dutta P, Metall Mater Trans B 42 (2011) 783.

Ludwig A, and Wu M, Metall Mater Trans A 33 (2002) 3673.

Wu M, Ludwig A, Bührig-Polaczek A, Fehlbier M, and Sahm P R, Int J Heat Mass Transf 46 (2003) 2819.

Wu M, and Ludwig A, Mater Sci Eng A 413–414 (2005) 192.

Wu M, Ludwig A, and Luo J, Mater Sci Forum 475–479 (2005) 2725.

Ludwig A, and Wu M, Mater Sci Eng A 413–414 (2005) 109.

Wang T, Wu M, Ludwig A, Abondano M, Pustal B, and Bührig-Polaczek A, Int J Cast Met Res 18 (2005) 221.

Wu M, and Ludwig A, Metall Mater Trans A 37 (2006) 1613.

Wu M, and Ludwig A, in 11th International Conference on Modeling of Casting, Welding and Advanced Solidification Processes (MCWASP XI), Opio, France, (eds) Gandin C-A, and Bellet M (2006), p 291.

Wang T M, Lin T J, Cao Z Q, Jin J Z, Grimmig T, Bührig-Polaczek A, Wu M, and Ludwig A, Acta Metall Sin 42 (2006) 591.

Wu M, and Ludwig A, Metall Mater Trans A 38 (2007) 1465.

Wu M, and Ludwig A, Acta Mater 57 (2009) 5621.

Wu M, and Ludwig A, Acta Mater 57 (2009) 5632.

Wu M, Fjeld A, and Ludwig A, Comput Mater Sci 50 (2010) 32.

Wu M, Ludwig A, and Fjeld A, Comput Mater Sci 50 (2010) 43.

Kharicha A, Stefan-Kharicha M, Ludwig A, and Wu M, IOP Conf Ser Mater Sci Eng 33 (2012) 012042.

Wu M, Ahmadein M, Kharicha A, Ludwig A, Li J, and Schumacher P, IOP Conf Ser Mater Sci Eng 33 (2012) 012075.

Wu M, Li J, Kharicha A, Ludwig A, in 1st International Conference on Ingot Casting, Rolling and Forging (2012), p 1.

Li J, Wu M, Ludwig A, and Kharicha A, Int J Heat Mass Transf 72 (2014) 668.

Ishii M, and Zuber N, AIChE J 25 (1979) 843.

Ni J, and Beckermann C, Metall Trans B 22 (1991) 349.

Ludwig A, Vakhrushev A, Holzmann T, Wu M, and Kharicha A, IOP Conf Ser Mater Sci Eng 84 (2015) 012102.

Wang C Y, Ahuja S, Beckermann C, and De Groh III H C, Metall Mater Trans B 26 (1995) 111.

Ludwig A, Kharicha A, Hölzl C, Domitner J, Wu M, and Pusztai T, Eng Anal Bound Elem 45 (2014) 29.

Combeau H, Založnik M, Hans S, and Richy P E, Metall Mater Trans B 40 (2009) 289.

Wu M, Li J, Ludwig A, and Kharicha A, Comput Mater Sci 79 (2013) 830.

Kozlowski P F, Thomas B G, Azzi J A, and Wang H, Metall Mater Trans A 23 (1992) 903.

Acknowledgments

This work was financially supported by the FWF Austrian Science Fund (P22614-N22), FFG Bridge Early Stage (No. 3893791), and the Austrian Federal Ministry of Economy, Family and Youth and the National Foundation for Research, Technology and Development within the framework of the Christian Doppler Laboratory for Advanced Process Simulation of Solidification and Melting.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ludwig, A., Vakhrushev, A., Wu, M. et al. Simulation of Crystal Sedimentation and Viscoplastic Behavior of Sedimented Equiaxed Mushy Zones. Trans Indian Inst Met 68, 1087–1094 (2015). https://doi.org/10.1007/s12666-015-0651-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0651-4