Abstract

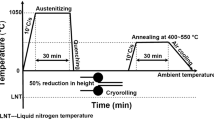

The aim of this work was to produce ultrafine grained low carbon steel (0.13 wt% carbon) by cold compression and subsequent annealing of lath martensite and study its formation kinetics. In this regard, the martensitic specimens were first cold compressed by 65 % and then annealed at 723, 773 and 823 K for various times ranging between 0 and 120 min. Results showed that annealing of the cold-compressed martensitic specimen at 823 K for 90 min led to the formation of ferrite grains with a mean size of 1.8 μm and small precipitates of Fe3C with sizes less than 300 nm. By using the Johnson–Mehl–Avrami–Kolmogorov analysis to describe the kinetics of ferrite recrystallization, the average value of time exponent (n) was found to be 0.96. The activation energy for the ferrite recrystallization was calculated as 83 kJ mol−1, which was consistent with the activation energy value for carbon diffusion in bcc iron (81 kJ mol−1).

Similar content being viewed by others

References

Ueji R and Tsuji N, Minamino Y, Koizumi Y, Sci Technol Adv Mater 5 (2004) 153.

Foroozmehr F, Najafizadeh A and Shafyeib A, Mater Sci Eng A 528 (2011) 5754.

Valiev R Z, Islamgaliev R K and Alexandrov I V, Prog Mater Sci 45 (2000) 103.

Park K T, Kim Y S, Lee J G and Shin D H, Mater Sci Eng A 293 (2000) 165.

Song R, Ponge D, Raabe D, Speer J G and Matlock D K, Mater Sci Eng A 441 (2006) 1.

Jamaati R, Toroghinejad M R, Edris H and Salmani M R, Trans Indian Inst Met 67 (2014) 787.

Ueji R, Tsuji N, Minamino Y and Koizumi Y, Acta Mater 50 (2002) 4177.

Ghassemali E, Kermanpur A and Najafizadeh A, J Nanosci Nanotechnol 10 (2010) 6177.

Hosseini S M, Najafizadeh A and Kermanpur A, J Mater Process Technol 211 (2011) 230.

Htun M S, Kyaw S T and Lwin K T, J Met Mater Miner 18 (2008) 191.

Get TTT and CCT Diagram with Steel Composition, in: http://www.calculations.ewi.org/vjp/secure/TTTCCTPlots.asp.

Brooks C R, Principles of the Heat Treatment of Plain Carbon and Low Alloy Steels, ASM International, Materials Park, OH, 1996.

Mazaheri Y, Kermanpur A, Najafizadeh A and Saeidi N, Acta Metall Sin (Engl Lett) 28 (2015) 249.

Kulakov M, Poole W J and Militzer M, Metall Mater Trans A 44 (2013) 3564.

Kooi B J, Phys Rev B 73 (2006) 1.

Fotsing E R, Phase Transformation Kinetics and Microstructure of Carbide and Diboride Based Ceramics, Technische Universität Clausthal, Clausthal-Zellerfeld (2005).

Huang J, Poole W J and Militzer M, Metall Mater Trans A 35 (2004) 3363.

Ghosh K S, Kumar A K and Mohan M K, Trans Indian Inst Met 61 (2008) 487.

Mclellan R B and Wasz M L, J Phys Chem Solids 54 (1993) 583.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ashrafi, H., Najafizadeh, A. Fabrication of the Ultrafine Grained Low Carbon Steel by Cold Compression and Annealing of Martensite. Trans Indian Inst Met 69, 1467–1473 (2016). https://doi.org/10.1007/s12666-015-0714-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0714-6