Abstract

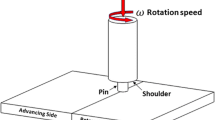

Friction stir processing (FSP) is a solid state process for refining the microstructure. Though FSP has shown significant impact in manufacturing industry, a detailed investigation is needed for further development of the process. The current article presented an experimental investigation on tool plunge stage by using different pin profiles such as conical, square, pentagonal and hexagonal. Influence of pin profiles on the temperature distribution around the tool during plunge has been studied. Thermocouples were placed at two different locations around the tool in the workpiece of Al–Zn–Mg–Cu alloy and temperatures were measured simultaneously at both the locations. FSP tools with different pin profiles under same process parameters were used to study the effects of pin profile on the temperature of the workpiece. Temperature profile was found to be asymmetric around the tool. During plunging stage, it was observed that the temperature due to plastic deformation at pin was less than the temperature caused by friction on the workpiece. Compared to other pin profiles, pentagon pin generated more temperature during the plunging. Further, tool shoulder had significant influence on the workpiece temperature compared to tool pin.

Similar content being viewed by others

References

Thomas W M, Nicholas E D, Needham J C, Murch M G, Templesmith P, and Dawes C J (1991). Patent Application No. 9125978.8.

Mishra R S, and Mahoney M W, Mater Sci Forum 357 (2001) 507.

Gibson B, Lammlein D H, Prater T J, Longhurst W R, Cox C D, Ballun M C, Dharmaraj K J, Cook G E, and Strauss A M, J Manuf Process 16 (2014) 56.

Patel V V, Badheka V J, and Kumar A, Procedia Technol 23 (2016) 537.

St. Węglowski M, Weld Int 28 (2014) 583.

Gan W-Y, Zheng Z, Zhang H, and Tao P, Trans Nonferrous Met Soc China 24 (2014) 975.

Kapoor R, Kandasamy K, Mishra R, Baumann J, and Grant G, Mater Sci Eng A 561 (2013) 159.

Węglowski M S, and Dymek S, Arch Civil Mech Eng 13 (2013) 186.

Behnagh R A, Besharati Givi M, and Akbari M, Mater Manuf Process 27 (2012) 636.

Alidokht S A, Abdollah-zadeh A, Soleymani S, Saeid T, and Assadi H, Mater Charact 63 (2012) 90.

Mahmoud T, and Mohamed S, Mater Sci Eng A 558 (2012) 502.

Sharma V, Prakash U, and Kumar B M, J Mater Process Technol 224 (2015) 117.

Patel V V, Badheka V, and Kumar A, Mater Manuf Process 31 (2016) 1573.

Bahrami M, Givi M K B, Dehghani K, and Parvin N, Mater Des 53 (2014) 519.

Salari E, Jahazi M, Khodabandeh A, Ghasemi-Nanesa H, Mater Des 58 (2014) 381.

Gadakh V S, and Adepu K, J Mater Res Technol 2 (2013) 370.

Mandal S, Rice J, and Elmustafa A, J Mater Process Technol 203 (2008) 411.

Venukumar S, Yalagi S, and Muthukumaran S, Trans Nonferrous Met Soc China 23 (2013) 2833.

Wang D-A, Chao C-W, Lin P-C, and Uan J-Y, J Mater Process Technol 210 (2010) 1942.

Patel V V, Sejani D J, Patel N J, Vora J J, Gadhvi B J, Padodara N R, and Vamja C D, Metallogr Microstruct Anal 5 (2016) 142.

Farias A, Batalha G F, Prados E F, Magnabosco R, and Delijaicov S, Wear 302 (2013) 1327.

Bisadi H, Rasaee S, and Farahmand M, Trans Indian Inst Met 67 (2014) 989.

Song M, and Kovacevic R, Int J Mach Tools Manuf 43 (2003) 605.

Hamilton C, Dymek S, and Sommers A, Int J Mach Tools Manuf 48 (2008) 1120.

Chen C, and Kovacevic R, Int J Mach Tools Manuf 43 (2003) 1319.

Patel V V, Badheka V, and Kumar A, Metallogr Microstruct Anal 5 (2016) 278. doi:10.1007/s13632-016-0285-x

Acknowledgments

Authors wish to thank to the RESPOND project (ISRO/RES/4/567/09-10) of ISRO for the machine facilities under this project. Authors are extending gratitude to the reviewer(s) for reviewing this paper.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Patel, V.V., Badheka, V.J. & Kumar, A. Influence of Pin Profile on the Tool Plunge Stage in Friction Stir Processing of Al–Zn–Mg–Cu Alloy. Trans Indian Inst Met 70, 1151–1158 (2017). https://doi.org/10.1007/s12666-016-0903-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-016-0903-y